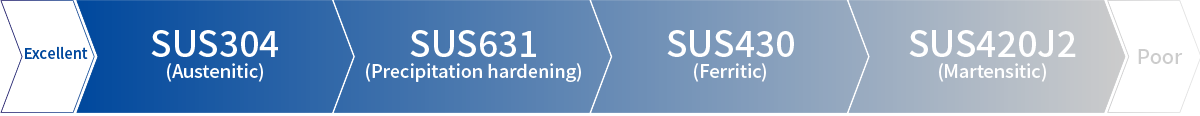

The relationships among austenitic steels (e.g. SUS304), ferritic steels (e.g. SUS430), martensitic steels (e.g. SUS420J2), and precipitation hardening steels (e.g. SUS631) is as shown in below figure. Click on any particular grade to see the details. To see the general properties of stainless steels, please refer to the table of contents below.

Please scroll horizontally to view.

| Type | Grade | Description *Links are to related pages |

|---|---|---|

| Austenitic |

*Reference Standards JIS G4305, G4313 |

Type 17-7 stainless steel with low chromium and nickel content of 18-8 stainless steel. Due to austenite instability, cold working causes martensitic transformation, which significantly increases mechanical strength and magnetic permeability. |

|

*Reference Standards JIS G4305, G4313 |

It is the most commonly used of the austenitic grades, and the most common form of 304 is 18-8 stainless steel. |

|

|

*Reference Standards JIS G4305 |

It has a lower carbon content than SUS304, and is particularly resistant to intergranular corrosion. It is also suitable for deep drawing due to its low hardness in the annealed state and low work hardenability. |

|

|

[TOKKIN Original Product] |

Austenitic materials are nonmagnetic in the solution heat-treated state and become magnetic when cold worked. However, TOKKIN 305M is a non-magnetic stainless steel designed to reduce this tendency. |

|

|

*Reference Standards JIS G4305 |

Its high nickel content and addition of molybdenum provide excellent workability and corrosion resistance. It is often used for drawing purposes, but its low carbon content and high nickel content make it less hard and weaker in work-hardening at annealed state. |

|

|

*Reference Standards JIS G4305 |

This material has a lower carbon content than SUS316, and has improved drawability and intergranular corrosion resistance. Materials for Bellows High Corrosion Resistant Stainless Steel Non-Magnetic Stainless Steels |

|

| Precipitation Hardening |

*Reference Standards JIS G4305, G4313 |

The most typical precipitation-hardened grade that can be heat-treated to increase strength while retaining the excellent performance of 18-8 stainless steel. Stainless Steels for Springs Precipitation Hardening Stainless Steels |

|

*Reference Standards JIS G 4313 |

While SUS631 is soft and can be processed in various ways in its solution heat-treated state, it requires intermediate hardening treatment to harden it. SUS632J1 is hard at room temperature even after solution treatment, and only one precipitation hardening treatment is required as a subsequent heat treatment. Stainless Steels for Springs Precipitation Hardening Stainless Steels |

|

|

[TOKKIN Original Product] |

A chromium-nickel-molybdenum precipitation hardening stainless steel used for applications requiring high strength and excellent weldability along with corrosion resistance. Materials for Bellows JIN™ Series Precipitation Hardening Stainless Steels |

|

| Ferritic |

*Reference Standards JIS G 4305 |

It is the most popular grade among stainless steels because of its high chromium content which is higher than all 13% chromium steels , and improves corrosion resistance. Furthermore, it is easy to machine since it does not undergo work transformation as austenitic steels do. |

|

[TOKKIN Original Product] |

It is much harder than SUS430, has sufficient formability, and can be press-worked with high speed and precision without drawing cracks. |

|

| Martensitic |

*Reference Standards JIS G4305, G4313 |

It is hardened by quenching, and a fairly wide range of mechanical properties can be obtained by adjusting tempering. The microstructure of our material is such that the carbides are completely spheroidal and can be easily machined in the annealed finish material. Martensitic Stainless Steels |

|

[TOKKIN Original Product] |

Because the carbon content is even higher than SUS420J2, after quench hardening the highest level of hardness among stainless steels can be obtained and is suitable for making blades. Martensitic Stainless Steels |

|

|

[TOKKIN Original Product] |

RB-X is a material that can be hardened by quenching and tempering heat treatment because of its high carbon content even though it is a stainless steel. It has higher chromium content than RB-S and excellent corrosion resistance by adding nickel and molybdenum. Since the carbon content is slightly lower than that of RB-S, the hardness after quenching is slightly lower. Martensitic Stainless Steels |

| Annealed austenitic stainless steels has significantly lower yield strength when compared to tensile strength, and higher elongation. Although SUS301 is an excellent material that can withstand complex processing, special consideration must be given to processing machinery, dies, lubricants, and work methods, etc., because work hardening and springback are extremely large. In addition, in the case of rolling finishing, durability differs depending on the direction of processing. For example, bending parallel to the rolling direction of the material is tend to cracking, so it is necessary to choose bending at perpendicular direction carefully. |

|

| Precipitation hardening stainless steels are characterized by the ability to increase strength through heat treatment. In particular, SUS631 is a soft metastable austenite phase in the annealed (solution heat-treated) state, making it a material that can withstand complex processing as well as austenitic stainless steel. By precipitation hardening (heat treatment) after machining, both workability and strength can be obtained. |

|

| The mechanical properties and workability of ferritic stainless steels are similar to those of medium-carbon steels. Annealed steel is tend to the stretcher strain seen in soft steels. To avoid this, a skin pass finish should be used. |

|

| Martensitic stainless steels are easier to machine than ferritic stainless steels at low carbon. High carbon content makes it hard even when annealed, making complex machining difficult. |

| Type | Grade | Chemical Compositions[mass%] | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cr | Ni | Mo | Fe | Others | ||

| Austenitic | SUS301 | 0.15 max | 1.00 max | 2.00 max | 0.045 max | 0.030 max | 16.00-18.00 | 6.00-8.00 | - | Bal. | - |

| SUS304 | 0.08 max | 1.00 max | 2.00 max | 0.045 max | 0.030 max | 18.00-20.00 | 8.00-10.50 | - | Bal. | - | |

| SUS304L | 0.030 max | 1.00 max | 2.00 max | 0.045 max | 0.030 max | 18.00-20.00 | 9.00-13.00 | - | Bal. | - | |

| TOKKIN™ 305M |

0.09 max | 0.60-1.00 | 1.40-1.80 | 0.045 max | 0.030 max | 18.00-19.00 | 12.00-13.00 | - | Bal. | - | |

| SUS316 | 0.08 max | 1.00 max | 2.00 max | 0.045 max | 0.030 max | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 | Bal. | - | |

| SUS316L | 0.030 max | 1.00 max | 2.00 max | 0.045 max | 0.030 max | 16.00-18.00 | 12.00-15.00 | 2.00-3.00 | Bal. | - | |

| Precipitation Hardening |

SUS631 (17-7PH) |

0.09 max | 1.00 max | 1.00 max | 0.040 max | 0.030 max | 16.00-18.00 | 6.50-7.75 | - | Bal. | Al 0.75-1.5 |

| SUS632J1 (15-7PH) |

0.09 max | 1.00-2.00 | 1.00 max | 0.040 max | 0.030 max | 13.50-15.50 | 6.50-7.75 | - | Bal. | Cu 0.40-1.0 Ti 0.20-0.65 |

|

| TOKKIN™ 350 |

0.07-0.11 | 0.50 max | 0.50-1.25 | 0.040 max | 0.030 max | 16.00-17.00 | 4.00-5.00 | 2.50-3.25 | Bal. | N 0.07-0.13 | |

| Ferritic | SUS430 | 0.12 max | 0.75 max | 1.00 max | 0.040 max | 0.030 max | 16.00-18.00 | - | - | Bal. | - |

| FS-1 | 0.08 max | 1.50-2.50 | 1.00 max | 0.040 max | 0.010 max | 16.00-18.00 | 1.50 max | - | Bal. | - | |

| Martensitic | SUS420J2 | 0.26-0.40 | 1.00 max | 1.00 max | 0.040 max | 0.030 max | 12.00-14.00 | - | - | Bal. | - |

| RB-S | 0.58-0.70 | 1.00 max | 1.00 max | 0.040 max | 0.015 max | 12.50-14.50 | - | - | Bal. | - | |

| RB-X | 0.36-0.42 | 1.00 max | 1.50 max | 0.040 max | 0.015 max | 13.00-14.5 | 0.50 max | 0.60-1.00 | Bal. | - | |

| Type | Grade | C | Si | Mn | P | S | Cr | Ni | Mo | Fe | Others |

| Chemical Compositions[mass%] | |||||||||||

| Condition | Temper/Finish | Description *Links are to related pages |

|---|---|---|

| Annealed | BA | Bright annealed after cold rolling. Materials with a BA finish are the softest, and the most suitable for highly sophisticated and complex processing. |

| Skin Passed | Skin Passed | The surface condition and mechanical properties are adjusted by light cold-rolling after annealing. Workability is equal to or slightly harder than BA finish. It also helps prevent stretcher strain, which tends to appear in annealed ferritic stainless steels. |

| 2B(Bright) | ||

| 2D(Dull) | ||

| Rolled (As-Rolled) *To be determined by cold rolling degree |

R | After annealing, the finished product is rolled according to the desired mechanical properties. The higher the rolling process rate, the higher the hardness and tensile strength, but the increased directionality and reduced elongation make complex processing more difficult. For SUS301, 304, 631, etc., the degree of cold-rolling is specified as 1/4H, 1/2H, 3/4H, H...etc. |

| 1/4H | ||

| 1/2H | ||

| 3/4H | ||

| H | ||

| EH | ||

| SEH |

| Bright | Cold rolling is performed with shiny rolls, and the surface is finished to a glossy state. |

|---|---|

| Dull | Cold-rolled with a uniformly roughened surface on the rolling rolls, the surface is finished to a pear-like, non-glossy state. |

| Polish | Abrasive material with a roughness suitable for your application and needs. Eg. Hairline finish |

Annealing is performed in the following cases.

Annealing conditions is as follows.

| Type | Temperature | Cooling |

|---|---|---|

| Austenitic | 1010~1150℃ | Rapid Cooling |

| Martensitic | 750~850℃ | Slow Cooling |

| Ferritic | 780~850℃ | Rapid or Slow Cooling |

Martensitic stainless steels can be hardened by quenching, but there are some differences when compared to carbon steel.

The maximum hardening hardness of each steel grade is as follows: Sub-zero treatment after quenching is particularly effective for high-carbon, high-temperature quenched grades.

| Grade | Max. Hardening Hardness [HV] |

Sub Zero Hardness [HV] |

|---|---|---|

| RB-S | 620~680 | 650~720 |

| SUS420J2 | 580~640 | 590~670HV |

Its hardness can be increased by heat treatment, but it also depends on the steel grade, some are hardened by a single heat treatment, while others require a two-step process.

Please refer to the precipitation hardening stainless steels page for precipitation hardening heat treatment conditions.

It most commonly occurs where the passive coating layer is physically damaged or chemically attacked. This creates a weak point where water or corrosive solutions attack the substrate. The pitting corrosion resistance (PRE) index, which is determined from the elemental content, is one of the guidelines for superiority or inferiority of pitting corrosion resistance.

*There are steel grades whose corrosion resistance has been greatly improved through composition adjustment and additional processing.

Spring Material is used for springs because it can obtain high strength through cold working and heat treatment.SUS301, SUS304, SUS631, SUS632J1, and SUS420J2 are the five common grades of stainless steel used in TOKKIN's spring manufacturing.

This grade is based on SUS304 (18Cr-8Ni), a typical austenitic stainless steel, and has stabilized austenite phase by increasing chemical composition such as nickel, manganese and chromium, making it less susceptible to magnetization even after cold rolling.

This is a steel grade with increased nickel and added molybdenum to SUS304, a typical austenitic stainless steel.

Stainless steel hardened by the precipitation of compounds and other substances through heat treatment. It has the advantages of austenitic stainless steel while its strength can be increased by heat treatment.

Stainless steel which can obtain extreme high strength through quenching.

Please click here to see the features of each steel grade.