Stainless Steels

Austenitic

SUS304 - UNS S30400 | Stainless Steel

Overview & Features

While not as strong as SUS301, it is possible to increase its strength by cold rolling, and can be used for spring components.

In addition, annealed or lightly rolled finishes have higher elongation and can withstand complex processing.

We supply a variety of stainless steels for springs as specified in JIS G4313.

Please refer to this page for the features and comparison of each grade of stainless steel for springs.

Examples of Applications

Vibration Motors/Haptics, FPC, Shielding Cases, Hinges, Variable Resistors, Injectors, Oil Rings, Printer Parts, Chains, Heaters (Heating Elements), Razor Blades Guards, Syringe Needles

Available Shapes

Manufacturable Range (COIL, SHEET)

Thickness

0.010-3.0mm

Width

3.0-300mm

Length

COIL or SHEET less than 2000mm

This is the manufacturing range of coils and sheets we manufacture.

For inquiries regarding procurement items, please contact us.

Standards

We manufacture in accordance with JIS G4313 standards.

Overseas standards are listed as equivalent or similar to our materials, so please use them as a reference.

JIS

SUS304 (G4313, G4305)

UNS

AISI

S30400

304

EN

1.4301

ISO

4301-304-00-I, X5CrNi18-10

GB

S30408, 06Cr19Ni10

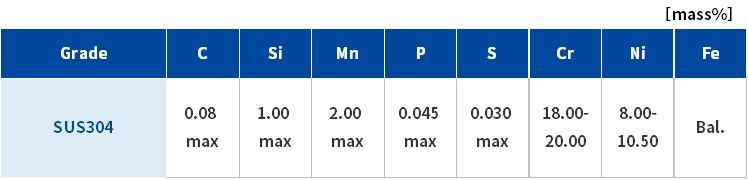

Chemical Composition

Physical Properties

Density

7.90 g/cm³

Specific Heat

502 J/(kg・K)

Electrical Resistivity

72 μΩ・cm

Young's Modulus

193 GPa

Thermal Expansion

17.3×10-6/K(0~100℃)

Thermal Conductivity

16.3 W/(m・K)

Melting Range

1380-1420 ℃

Magnetism

It is non-magnetic in the solution heat-treated state, but becomes weakly magnetic when processed.

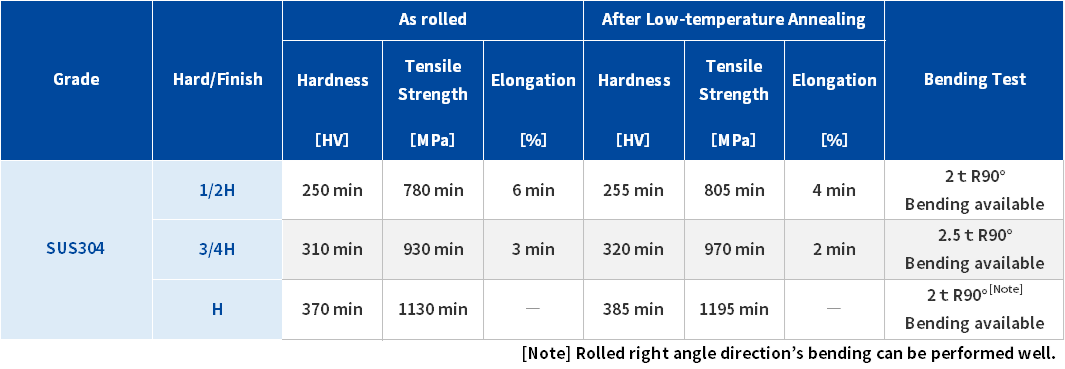

Mechanical Properties

Unless otherwise specified, we manufacture in accordance with JIS standards (table below), but you can also specify stricter standards or custom specifications.

Low-Temperature Annealing

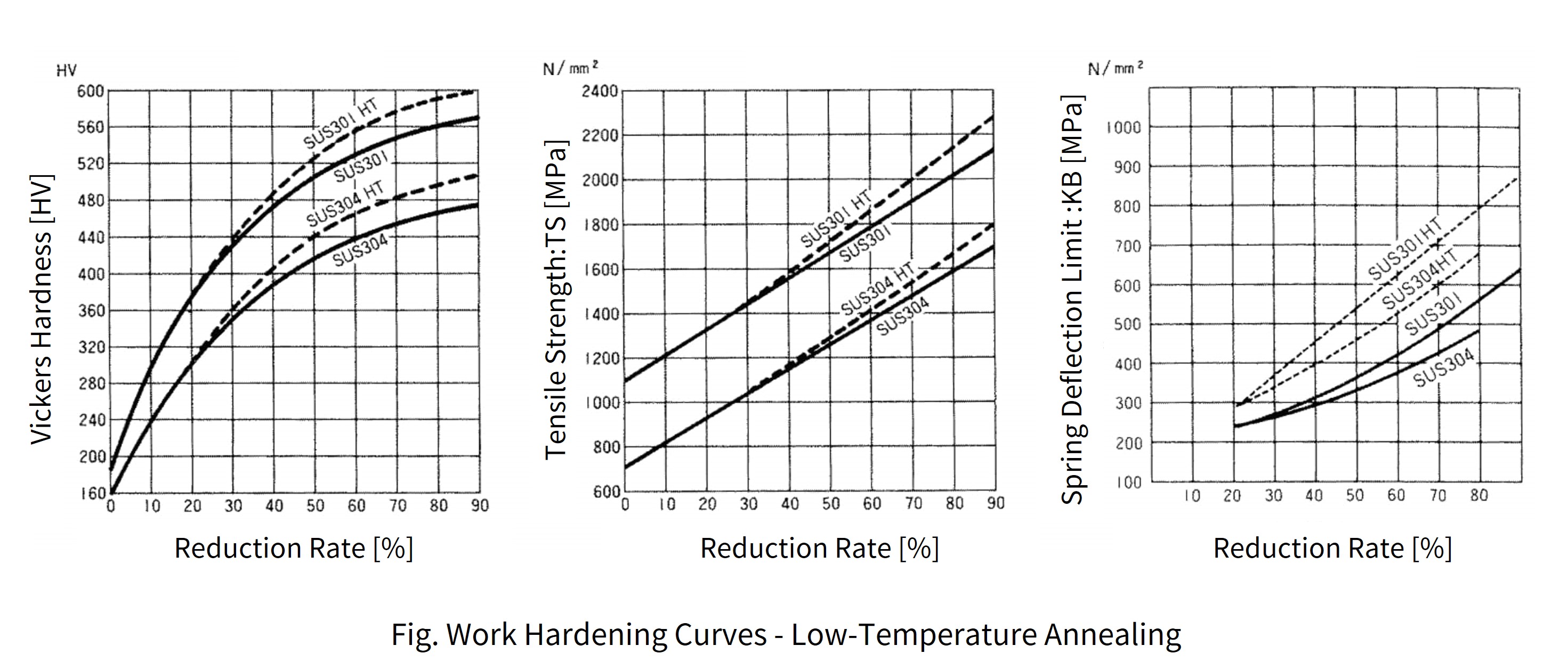

Stainless Steels for springs can be used as rolled, but if strong springiness is required, we recommend low-temperature annealing at about 400°C after part processing.

This low-temperature annealing must be performed after processing. If processing is performed on products that have already been low-temperature annealed, the effect of low-temperature annealing will be lost.

The best condition for low temperature annealing is heating at [400-420℃ for 1 to 2 hours] to obtain the best performance.

Depending on product performance, equipment, and working conditions, treatment at 200-450°C for an appropriate amount of time is also acceptable.

low-temperature annealing in the air forms oxide film(golden color) on surface, but this film can be easily removed by slight acidity or mechanical surface treatment.

As noted above, low-temperature annealing at [400-420℃] can obtain the best performance on mechanical properties, but corrosion resistance gets worse. If corrosion resistance is your priority, I recommend heat treatment is performed at[under 350℃].

In addition, if low-temperature annealing is performed with dirty oil, dust, or other foreign matter adhering to the material surface, it may be burned on to the surface of the material. Therefore, it is necessary to clean the surface as much as possible beforehand.

The effect of low-temperature annealing on mechanical properties is shown in the figure below.

Anisotropy

SUS301 s is manufactured by cold rolling and has necessarily anisotropy.

The higher the springiness, the higher the rolling ratio and thus the stronger the anisotropy, so anisotropy should be considered when using the product.

In general, strength (tensile strength, spring limit, yield point, elastic modulus, etc.)

is stronger in the direction perpendicular to the rolling direction and weakest in the direction parallel to it. Elongation shows the opposite trend. Therefore, when selecting a material that will be bent, please make sure that the bending axis is perpendicular to the rolling direction, or at most 45°.

Also, the higher the strength of the material, the less toughness it has and the greater the springback will be, therefore, please consider the processing conditions carefully before use.

Related Pages

Stainless Steels for Springs

This materials are possible to increase their hardness by rolling, they can be used as spring parts.

Ultrafine Grain Stainless Steel

nanoSUS™

nanoSUS™ a stainless steel in which the crystal grain size of the material is refined to about 1μm. The control of microstructure contributes to improving various properties such as strength, fatigue properties, and workability."

Stainless Steels

Stainless steel is an alloy of iron (Fe) with at least 10.5% chromium (Cr) and is used in a wide range of applications because it has good properties in terms of corrosion resistance, strength, workability, and heat resistance.

Stainless Steels Foils (Under t0.10mm)

We offer not only thin stainless steel foils, but also propose the appropriate steel grade and temper depending on specific application and use requirements, such as strength, workablility, magnetism, and corrosion resistance.