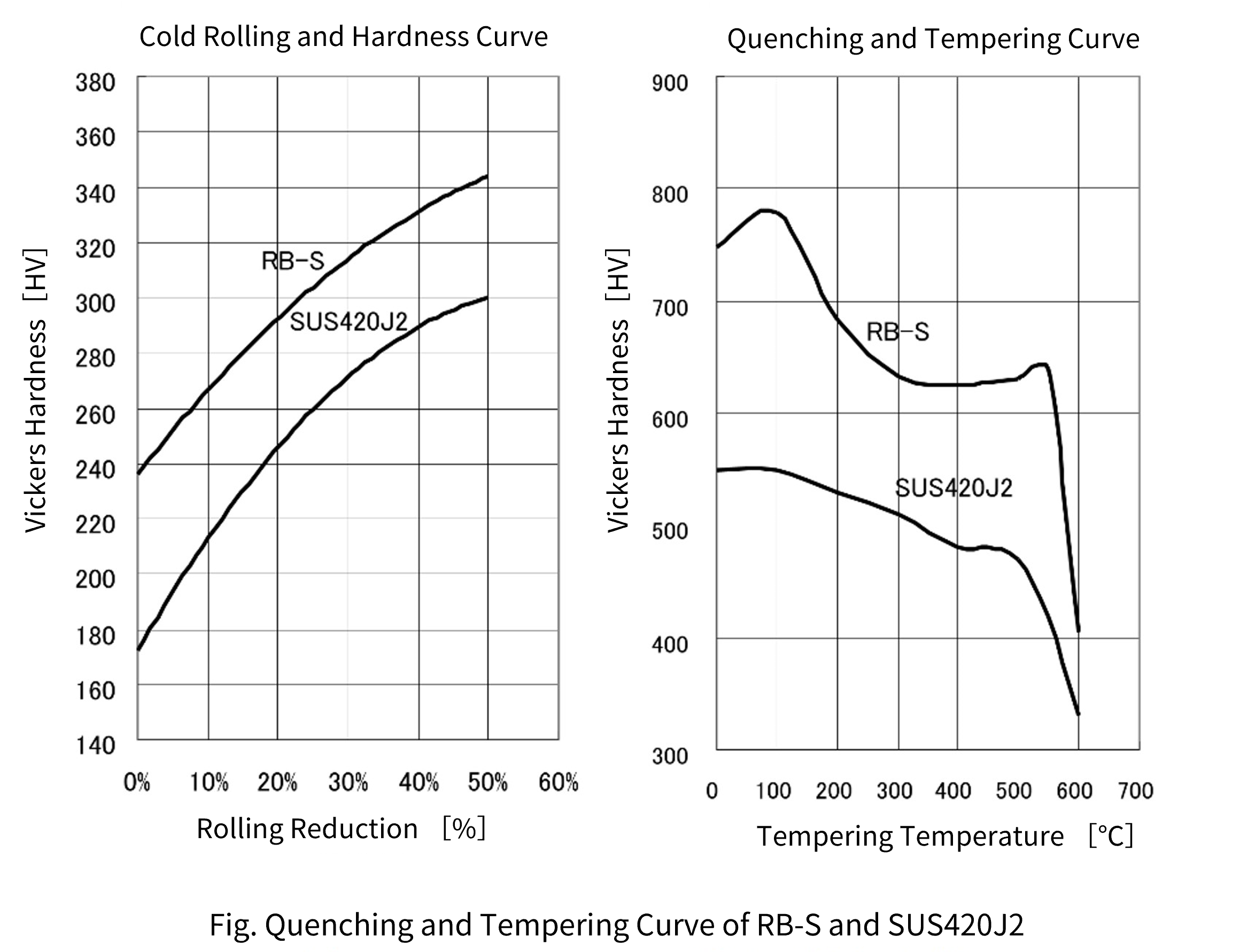

SUS420J2, RB-S, and RB-X are classified as martensitic stainless steels and can be hardened through quenching and tempering heat treatment.

Martensitic stainless steel contains high carbon content and can be hardened through quenching, resulting in high strength. Furthermore, adjusting the tempering conditions can achieve various mechanical properties.

It also has high heat resistance and work-hardening properties, so it is used in various fields as shown in the application section.

However, due to its high carbon content, it has the disadvantage of being the most rust-prone of all stainless steels, so it requires anti-rust treatment similar to iron.

Knitting Needles, Reed, Spinning Machine, Doctor Blades, Industrial Knives, Scale, Soldering Irons, Scrapers, HDD Parts, Bearing Parts, Springs

Thickness: 0.050~2.5mm

Width : 3.0~300mm

| It is classified as a martensitic stainless steel and because of its marketability and prce, it is widely used in various fields. Our annealed finish makes the carbides completely spheroidized, making processing easier. | |

| RB-S [TOKKIN Original Product] |

It is classified as a martensitic stainless steel and with a higher Carbon content compared to SUS420J2, great hardening occurs during quenching, it has the highest level of hardness among stainless steels.Because it is quite hard even after annealing, less suitable for complex processing, but it is an ideal material for blades. |

| RB-X [TOKKIN Original Product] |

Although it is a stainless steel, RB-X can be hardened through quenching and tempering heat treatment because of its high Carbon content.It has superior corrosion resistance than RB-S due to higher Chromium content and addition of Nickel and Molybdenum. Because its Carbon content is slightly lower than RB-S, the hardness after quenching is slightly lower. |

Equivalent overseas standards are for reference only.

RB-S and RB-X are TOKKIN original product.

Please scroll horizontally to view.

| Grade | Japan | USA | Europe | International | |

|---|---|---|---|---|---|

| JIS G4313,G4305 | UNS | AISI/ASTM | EN | ISO | |

| SUS420J2 | SUS420J2 | S42000 | 420 | 1.4028 1.4034 |

X30Cr13 |

Please scroll horizontally to view.

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo | Fe |

|---|---|---|---|---|---|---|---|---|---|

| SUS420J2 | 0.26~0.40 | ≦1.00 | ≦1.00 | ≦0.040 | ≦0.030 | 12.00~14.00 | - | - | Bal. |

| RB-S | 0.58~0.70 | ≦1.00 | ≦1.00 | ≦0.040 | ≦0.015 | 12.50~14.50 | - | - | Bal. |

| RB-X | 0.36~0.42 | ≦1.00 | ≦1.50 | ≦0.040 | ≦0.015 | 13.00~ 14.50 |

≦0.50 | 0.60~1.00 | Bal. |

Please scroll horizontally to view.

| Grade | Density [g/cm3 ] |

Specific Heat [J/(kg・K)] |

Electrical Resistance [μΩ・cm] |

Young's Modulus [GPa] |

Thermal Expansion Coefficient [×10-6/K] |

Thermal Conductivity [W/(m・K)] |

Melting Point [℃] |

Magnetism |

|---|---|---|---|---|---|---|---|---|

| SUS420J2 | 7.75 | 460 | 55 | 200 | 10.3 (0~100℃) |

24.7 | 1454~1510 | Magnetism |

| RB-S | 7.70 | 430 | 60 | 220 | - | 25.0 | - | Magnetism |

Please scroll horizontally to view.

| Grade | Hardness[HV] | ||

|---|---|---|---|

| As Annealed / As Rolled | After Heat Treatment (Reference Values) |

||

| Annealed | Full Hard | Quenching and Tempering | |

| SUS420J2 | 150~200 | 280~320 | 450~550 |

| RB-S | 230~270 | 310~360 | 600~750 |

| RB-X | 190~230 | 300~350 | 500~650 |

Please scroll horizontally to view.

| Grade | Temper / Finish | Tensile Strength [N/m㎡] |

Elongation [%] |

|---|---|---|---|

| SUS420J2 | Annealed | 540~655 | 20~30 |

| Full Hard | 880~1030 | 1~3 |