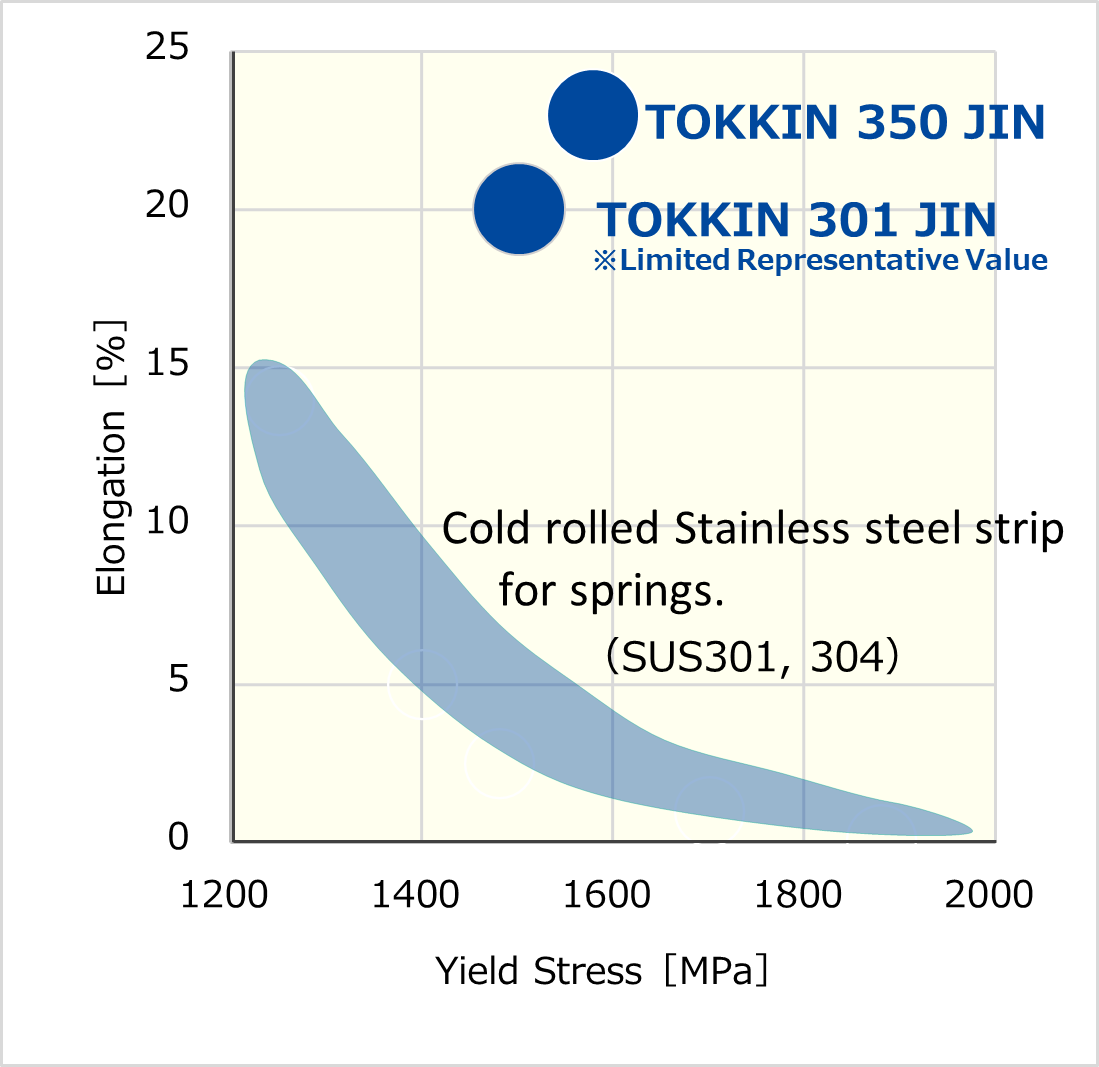

This is an excellent material series with high strength and excellent workability that cannot be obtained with ordinary manufacturing methods, achieved through TOKKIN's proprietary "JIN™" manufacturing process.

The balance of Yield stress (YS) exceeds 35,000 MPa x Elongation (EL) is among the highest in the world and received

TOKKIN 350 JIN and TOKKIN 301 JIN are available, which you can select according to the required properties.

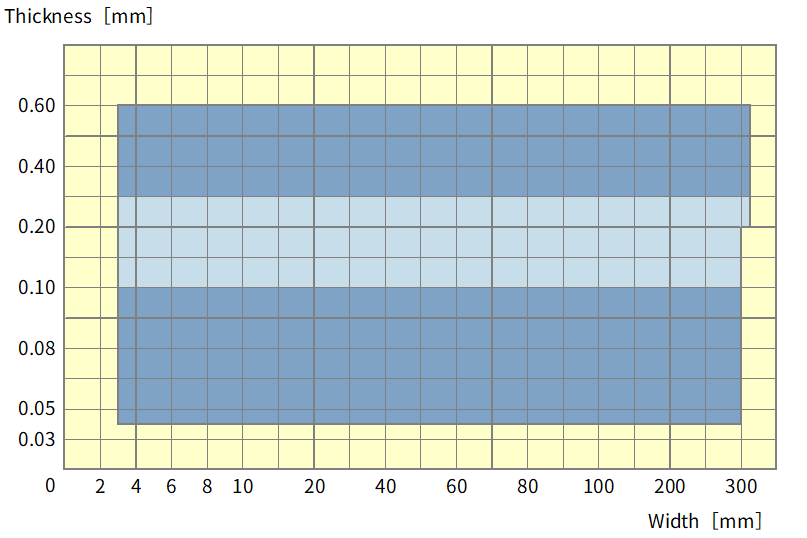

Thickness : 0.030mm-0.60mm *Contact Sales if you need 0.030mm-0.10mm and 0.30mm-0.60mm.

Width : 3.0mm-300mm

Length : COIL or SHEET less than L2000mm

Manufacturing range

Please Contact us for more detail

The balance diagram of yield strength (YS) and elongation (EL) between JIN series and general stainless steels SUS301 and SUS304 for springs is shown in the figure on the right.

JIN series has both high strength and ductility, so that it is possible to realize shapes that have been difficult to fabricate with conventional stainless steels for springs.

Please scroll horizontally to view.

| Materials | C | Si | Mn | P | S | Cr | Ni | Mo | Fe | N |

|---|---|---|---|---|---|---|---|---|---|---|

| TOKKIN 350 JIN (TOKKIN 350) |

0.07~0.11 | ≦0.50 | 0.50~1.25 | ≦0.040 | ≦0.030 | 16.00~17.00 | 4.00~5.00 | 2.50~3.25 | Bal. | 0.07~0.13 |

| TOKKIN 301 JIN (SUS301) |

≦0.15 | ≦1.00 | ≦2.00 | ≦0.045 | ≦0.030 | 16.00~18.00 | 6.00~8.00 | - | Bal. | - |

The mechanical properties of TOKKIN 350 JIN and TOKKIN 301 JIN are shown in the table below.

*Typical values are examples and are not guaranteed values.

Please scroll horizontally to view.

| Yield Strength [MPa] |

Tensile Strength [MPa] |

Elongation [%] |

Hardness [HV] |

||

|---|---|---|---|---|---|

| TOKKIN 350 JIN | Spec | 1430 min | 1500 min | 16 min | 460 min |

| Typical Value | 1523 | 1567 | 23 | 472 | |

| TOKKIN 301 JIN | Reference Spec* | 400 min | 1500 min | 12 min | - |

| Typical Value | 1503 | 1586 | 20 | 496 | |

| SUS301-H | Typical Value | 1500 | 1570 | 9 | 445 |

| SUS301-3/4H | Typical Value | 900 | 1370 | 22 | 390 |

[Note] *As for specification value, please contact us for more details.

This is a 42-second movie of a tensile testing comparing TOKKIN 350 JIN with a common SUS301-H.

You can also see the difference in elongation rate and SS curve.

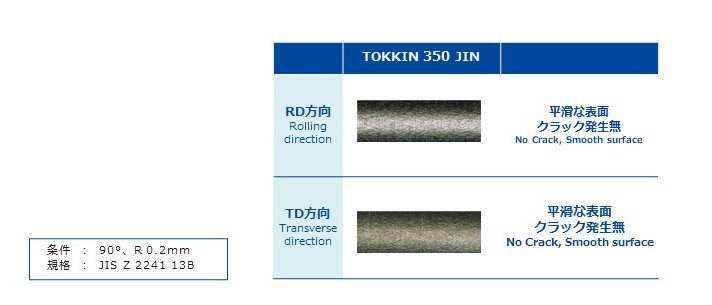

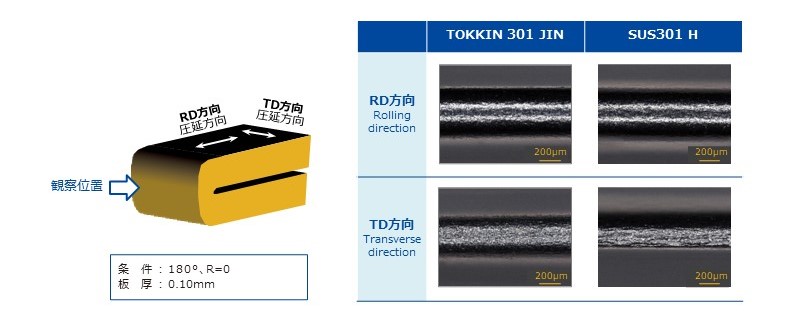

TOKKIN 350 JIN and TOKKIN 301 JIN both have low anisotropy during processing, so they can be used without concern for the direction of processing.

Because SUS301 has strong anisotropy, it is prone to Cracking when bent in the Transverse Direction (parallel to the rolling direction).

TOKKIN 350 JIN and TOKKIN 301 JIN have high pitting corrosion resistance.

nanoSUS™ is a stainless steel that has ultrafine grained (UFG) microstructures with average grain sizes smaller than 1 μm.Compared to normal material, various property improvements can be expected, such as improved strength, fatigue properties, and workability by controlling the microstructure.

There are several types of bellows, such as welded bellows and molded bellows, depending on the manufacturing method.For stainless steels and nickel alloys for bellows, Please refer to this page.

Spring Material is used for springs because it can obtain high strength through cold working and heat treatment.SUS301, SUS304, SUS631, SUS632J1, and SUS420J2 are the five common grades of stainless steel used in TOKKIN's spring manufacturing.