Spring Material is specified in JIS G 4313 and is used for springs because it can obtain high strength through cold working and heat treatment. SUS301, SUS304, SUS631, SUS632J1, and SUS420J2 are the five common grades of stainless steel used in TOKKIN's spring manufacturing. Depending on the application and requested specifications, TOKKIN can assist you in selecting the correct material for you. TOKKIN provides stainless steel foil and other specifications (plate thickness and temper) that are not generally distributed, in optimal conditions, because we can produce to order from small lots.

Springs, Springs for Seat Belts, Other Automotive Parts, Tactile Switches, Membrane Switches, Clocks, Stationery

Thickness : 0.010mm-2.5mm

*Availability may vary by steel grade.

Width : 3.0mm-300mm *Contact Sales if your desired values is over 300mm.

Length : COIL or SHEET less than L2000mm

Please scroll horizontally to view.

| Type | Grade | Description |

|---|---|---|

| Austenitic | SUS301 | Most widely used stainless steels, chosen for its very good work hardening properties, corrosion resistance and workability.

|

| SUS304 | ||

| Precipitation Hardening | SUS631 (17-7PH) |

This is a typical precipitation hardening stainless steel grade whose hardness can be increased by heat treatment, but it is a difficult material to obtain due to its relatively small distribution volume. Material A (solution-treated) is soft in austenite phase and can be processed more complexly than other grades, but it requires subsequent heat treatments twice, so it takes some time and effort. Material C (cold-rolled) is supplied after cold working to an appropriate hardness. Compared to Material A, Material C cannot be processed complexly. However, by applying heat treatment under optimum conditions, Material C can achieve a strength second only to high-carbon martensitic hardened materials. |

| SUS632J1 (15-7PH) |

SUS632J1 has high strength even in solution heat-treated condition because of its martensitic phase, and a certain degree of strength can be obtained without cold working, which deteriorates the anisotropy. You need precipitation hardening heat treatment only once, which is very easy. Since there is little difference in strength at welded joints, it is sometimes used for steel belts and other applications that involve welding. |

|

| Martensitic | SUS420J2 | SUS420J2 is a material that can be hardened by quenching and tempering heat treatment due to its high carbon content. In our annealed finish condition, the carbides are completely spheroidized, which makes machining easier and provides excellent hardenability.

|

Unless otherwise specified, we manufacture in accordance with JIS standards. Equivalent overseas standards are for reference only.

Please scroll horizontally to view.

| Grade | Japan | the U.S.A | Europe | International | |

|---|---|---|---|---|---|

| JIS G4313 | UNS | AISI/ASTM | EN | ISO | |

| SUS301 | SUS301 | S30100 | 301 | 1.4319 | X5CrNi17-7 |

| SUS304 | SUS304 | S30400 | 304 | 1.4301 | X5CrNi18-10 |

| SUS631 (17-7PH) |

SUS631 | S17700 | 631 | 1.4568 | X7CrNiAl17-7 |

| SUS632J1 (15-7PH) |

SUS632J1 | - | - | - | - |

| SUS420J2 | SUS420J2 | S42000 | 420 | 1.4028 1.4034 |

X30Cr13 X30Cr13 |

Please scroll horizontally to view.

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo | Fe | Others |

|---|---|---|---|---|---|---|---|---|---|---|

| SUS301 | 0.15 max | 1.00 max | 2.00 max | 0.045 max | 0.030 max | 16.00-18.00 | 6.00-8.00 | - | Bal. | - |

| SUS304 | 0.08 max | 1.00 max | 2.00 max | 0.045 max | 0.030 max | 18.00-20.00 | 8.00-10.50 | - | Bal. | - |

| SUS631 (17-7PH) |

0.09 max | 1.00 max | 1.00 max | 0.040 max | 0.030 max | 16.00-18.00 | 6.50-7.75 | - | Bal. | Al 0.75-1.5 |

| SUS632J1 (15-7PH) |

0.09 max | 1.00-2.00 | 1.00 max | 0.040 max | 0.030 max | 13.50-15.50 | 6.50-7.75 | - | Bal. | Cu 0.40-1.00 Ti 0.20-0.65 |

| SUS420J2 | 0.26-0.40 | 1.00 max | 1.00 max | 0.040 max | 0.030 max | 12.00-14.00 | 0.60 max | - | Bal. | - |

Please scroll horizontally to view.

| Grade | Density [g/cm3 ] |

Specific Heat [J/(kg・K)] |

Electrical Resistance [μΩ・cm] |

Young's modulus [GPa] |

Thermal Expansion [×10-6/K] |

Thermal Conductivity [W/(m・K)] |

Melting Point [℃] |

Magnetism |

|---|---|---|---|---|---|---|---|---|

| SUS301 | 7.93 | 502 | 72 | 193 | 16.9 (0-100℃) |

16.3 | 1380-1420 | Nonmagnetic in the solution heat-treated condition, but becomes weakly magnetic when processed. |

| SUS304 | 7.90 | 502 | 72 | 193 | 17.3 (0-100℃) |

16.3 | 1380-1420 | Nonmagnetic in the solution heat-treated condition, but becomes weakly magnetic when processed. |

| SUS631 (17-7PH) |

7.81 | 420 | 79 | 200 | 15.3 (25-100℃) |

16.3 (100℃) |

1414-1447 | Nonmagnetic in the solution heat-treated condition, but becomes quite strongly magnetic when processed. |

| SUS632J1 (15-7PH) |

7.74 | 502 | 100 | 196 | 10.9 (0-100℃) |

15.9 (100℃) |

- | Magnetism |

| SUS420J2 | 7.75 | 460 | 55 | 200 | 10.3 (0-100℃) |

24.7 | 1454-1510 | Magnetism |

Please scroll horizontally to view.

| As Rolled | After Low-temperature Annealing | Bending Test | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Grade | Temper /Finish |

Hardness [HV] |

Tensile Strength [MPa] |

Elongation [%] |

Spring Deflection Limit [MPa] |

Hardness [HV] |

Tensile Strength [MPa] |

Elongation [%] |

Spring Deflection Limit [MPa] |

|

| SUS301 | 1/4H | 250 min | 860 min | 25 min | - | 253 min | 880 min | 20 min | - | 1tR90°Bending Available |

| 1/2H | 310 min | 930 min | 10 min | (315 min) | 315 min | 960 min | 8 min | (390 min) | 2tR90°Bending Available | |

| 3/4H | 370 min | 1130 min | 5 min | (390 min) | 380 min | 1175 min | 4 min | (540 min) | 2.5tR90°Bending Available | |

| H | 430 min | 1320 min | - | (490 min) | 440 min | 1400 min | - | (655 min) | [Note]4tR90°Bending Available | |

| EH | 490 min | 1570 min | - | (590 min) | 505 min | 1665 min | - | (785 min) | - | |

| SEH | 530 min | 1740 min | - | (650 min) | 550 min | 1840 min | - | (590 min) | [Note]2tR90°Bending Available | |

| SUS304 | 1/2H | 250 min | 780 min | 6 min | (275 min) | 255 min | 805 min | 4 min | (315 min) | 2tR90°Bending Available |

| 3/4H | 310 min | 930 min | 3 min | (335 min) | 320 min | 970 min | 2 min | (430 min) | 2.5tR90°Bending Available | |

| H | 370 min | 1130 min | - | (390 min) | 385 min | 1195 min | - | (590 min) | [Note]2tR90°Bending Available | |

[Note] Rolled right angle direction`s bending can be performed well.

Please scroll horizontally to view.

| As Annealed / As Rolled | As Precipitation Hardened | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Grade | Condition | Temper/Finish | Hardness [HV] |

Tensile Strength [MPa] |

Elongation [%] |

V bend 0.5t |

W bend 1.0t |

Heat Treatment | Hardness [HV] |

Tensile Strength [MPa] |

Yield Strength [MPa] |

Spring Deflection Limit [MPa] |

| SUS631 | Condition A | BA, 2B | 200 max |

1030 max |

20 min |

R90° | R90° | TH1050 | 345 min |

1140 min |

960 min |

- |

| RH950 | 392 min |

1230 min |

1030 min |

- | ||||||||

| Condition C | 1/2H | 350 min |

1080 min |

5 min |

1.5t R90° | 2.0t R90° | CH | 380 min |

1230 min |

880 min |

635 min |

|

| 3/4H | 400 min |

1180 min |

- | - | - | 450 min |

1420 min |

1080 min |

835 min |

|||

| H | 450 min |

1420 min |

- | - | - | 530 min |

1720 min |

1320 min |

980 min |

|||

| EH | 480 min |

1620 min |

- | - | - | 560 min |

1900 min |

1570 min |

- | |||

Please scroll horizontally to view.

| As Rolled | As Precipitation Hardened | ||||||

|---|---|---|---|---|---|---|---|

| Grade | Temper /Finish |

Hardness [HV] |

Tensile Strength [MPa] |

Elongation [%] |

Hardness [HV] |

Tensile Strength [MPa] |

Elongation [%] |

| SUS632J1 | 1/2H | 350 max | 1200 max | 1250 min | 400 min | 1300 min | 1200 min |

| 3/4H | 420 max | 1450 max | 1500 min | 480 min | 1550 min | 1400 min | |

Please scroll horizontally to view.

| As Annealed / As Rolled | After Quenching and Tempering (Reference Values) |

||||

|---|---|---|---|---|---|

| Grade | Temper /Finish |

Hardness [HV] |

Tensile Strength [MPa] |

Elongation [%] |

Hardness [HV] |

| SUS420J2 | Annealed | 150-200 | 540-655 | 1250 min | 450-550 |

| Full Hard | 280-320 | 880-1030 | 1-3 | ||

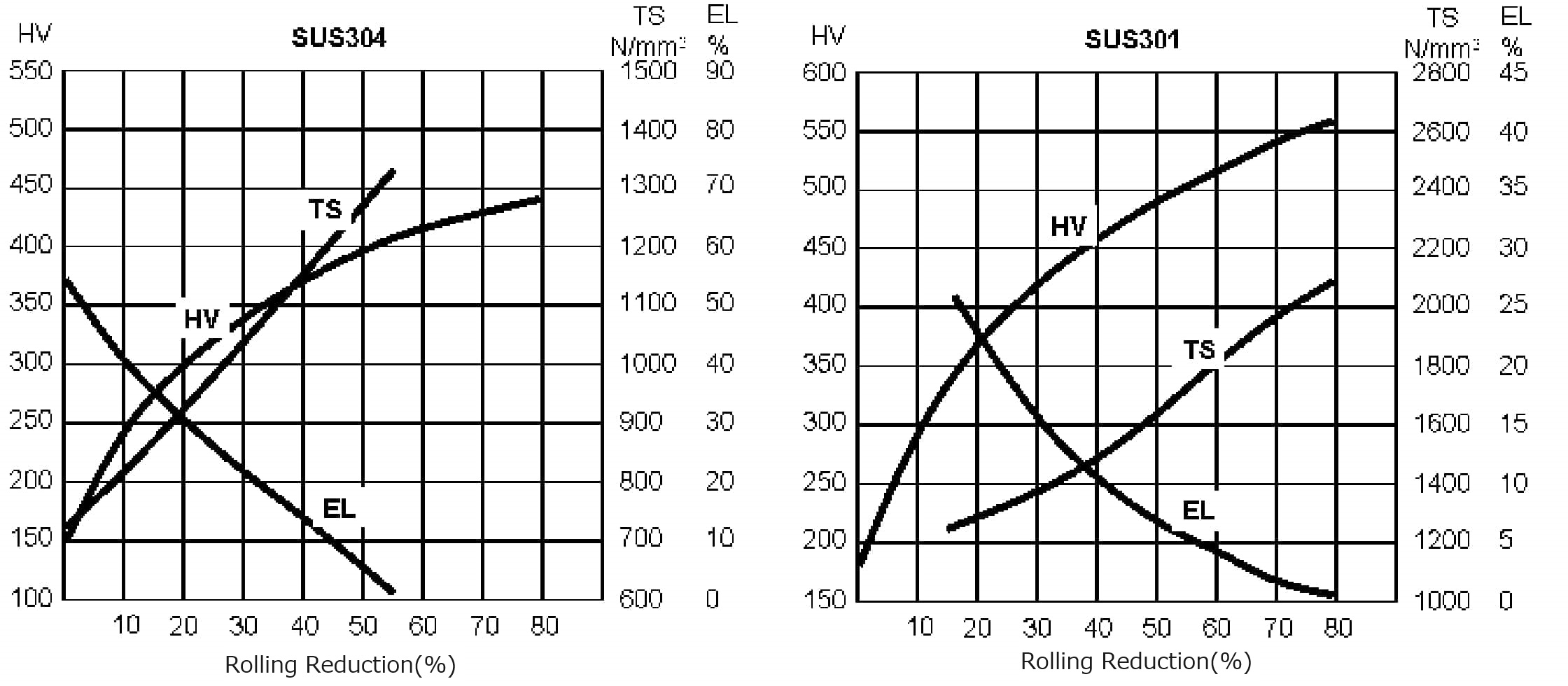

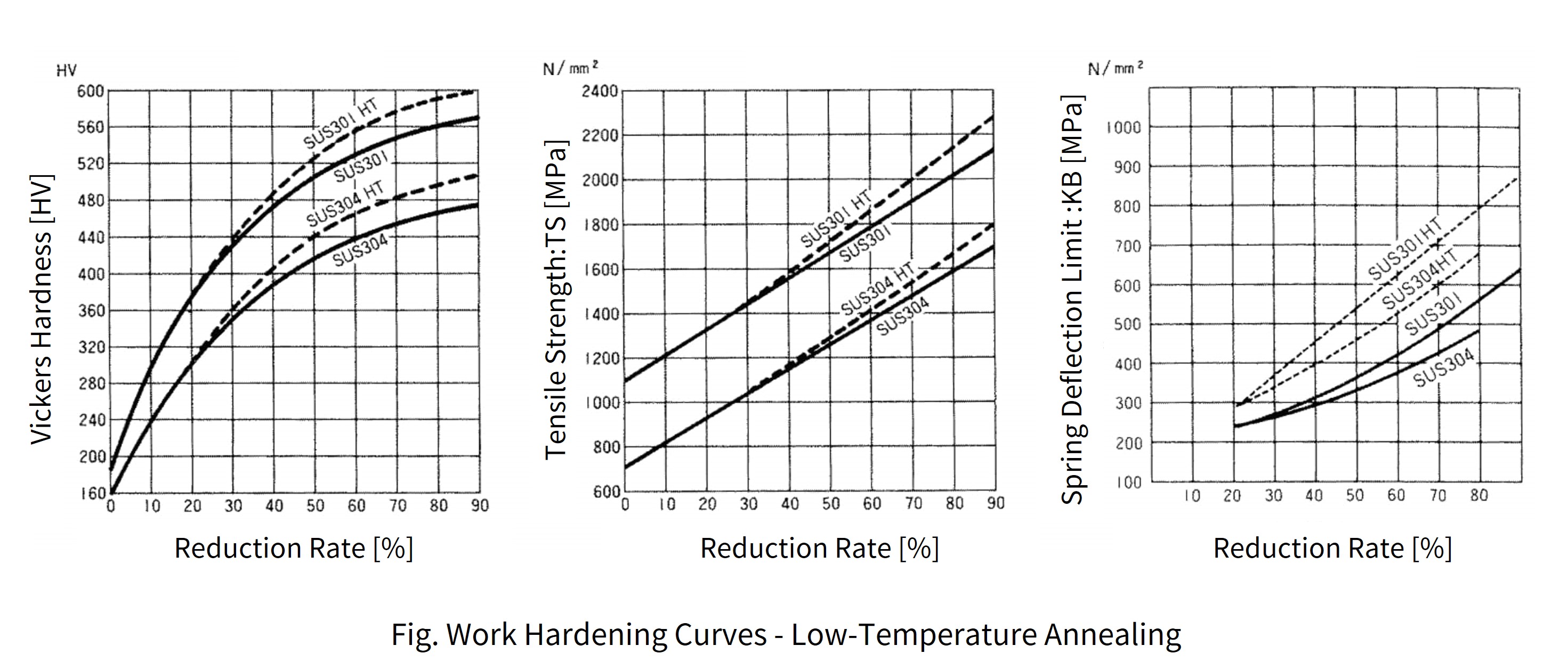

Stainless steels for springs is manufactured by cold rolling and has necessarily anisotropy.

Therefore, it is necessary to take anisotropy into consideration when using the material. In general, strength (tensile strength, spring limit, yield point, elastic modulus, etc.) is stronger in the direction perpendicular to the rolling direction and weakest in the direction parallel to it. Elongation shows the opposite trend. Therefore,when selecting a material that will be bent, please make sure that the bending axis is perpendicular to the rolling direction, or at most 45°.

Also, the higher the strength of the material, the less toughness it has and the greater the springback will be ,therefore, please consider the processing conditions carefully before use.

SUS301 and SUS304 can be used as rolled, but if strong springiness is desired, we recommend low-temperature annealing at about 400°C after part processing. This low-temperature annealing must be performed after processing. If processing is performed on a product that has already been low-temperature annealed, the effect of low-temperature annealing will be lost. Please refer to each steel grade page for heat treatment conditions.

SUS420J2 can be hardened by quenching and tempering.

Please refer to the SUS420J2 page for heat treatment conditions.

We can also provide quenched and tempered materials.

We can make it to foils (less than 0.10 mm thick) in all the stainless steels we manufacture

This grade is based on SUS304 (18Cr-8Ni), a typical austenitic stainless steel, and has stabilized austenite phase by increasing chemical composition such as nickel, manganese and chromium, making it less susceptible to magnetization even after cold rolling.