Stainless Steels

Austenitic

TOKKIN™ 305M - UNS S30500

| Non-Magnetic Stainless Steel

Overview & Features

TOKKIN 305M is adjusted these content at the higher level within the range of JIS SUS305, it exhibits increased stability compared to the typical SUS305.

Additionally, with a higher nickel (Ni) content, it has excellent processability and corrosion resistance.

Examples of Applications

Camera Modules/Components, Communication Equipment Parts, Medical Equipment, Indwelling Needles, Motor Parts

*Due to its non-magnetic properties, it is used for applications where magnetism is not desired, such as in electronic components.

Available Shapes

Manufacturable Range (COIL, SHEET)

Thickness

0.010-1.5mm

Width

3.0-300mm

Length

COIL or SHEET less than 2000mm

This is the manufacturing range of coils and sheets we manufacture.

Standards

TOKKIN's own grade of steel.

Overseas standards are listed as equivalent or similar to our materials, so please use them as a reference.

JIS

SUS305 (G4305)

UNS

AISI

S30500

305

EN

1.4303

ISO

4303-305-00-I, X4CrNi18-12

GB

S30510, 10Cr18Ni12

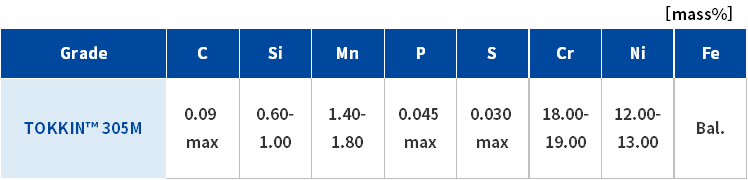

Chemical Composition

Physical Properties

Density

7.93 g/cm³

Specific Heat

502 J/(kg・K)

Electrical Resistivity

72 μΩ・cm

Young's Modulus

193 GPa

Thermal Expansion

17.3×10-6/K

Thermal Conductivity

16.3 W/(m・K) (100℃)

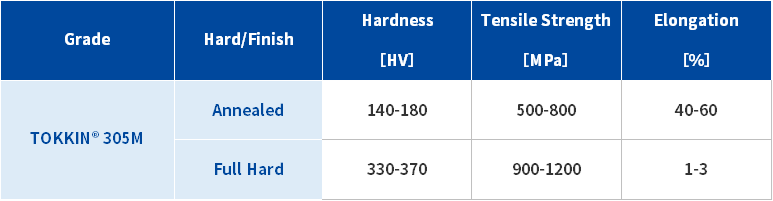

Mechanical Properties

The table below shows approximate values of mechanical properties for annealed finish and full hardened finish.

We can manufacture products in the desired hardness (finish) between annealed finish and full hardened finish, but some finishes may not be available depending on the plate thickness, so please contact us first.

*For ultra-thin foil, soft materials such as annealed or 2B finish may not be applicable due to concerns about defects (folding, wrinkling, etc.).

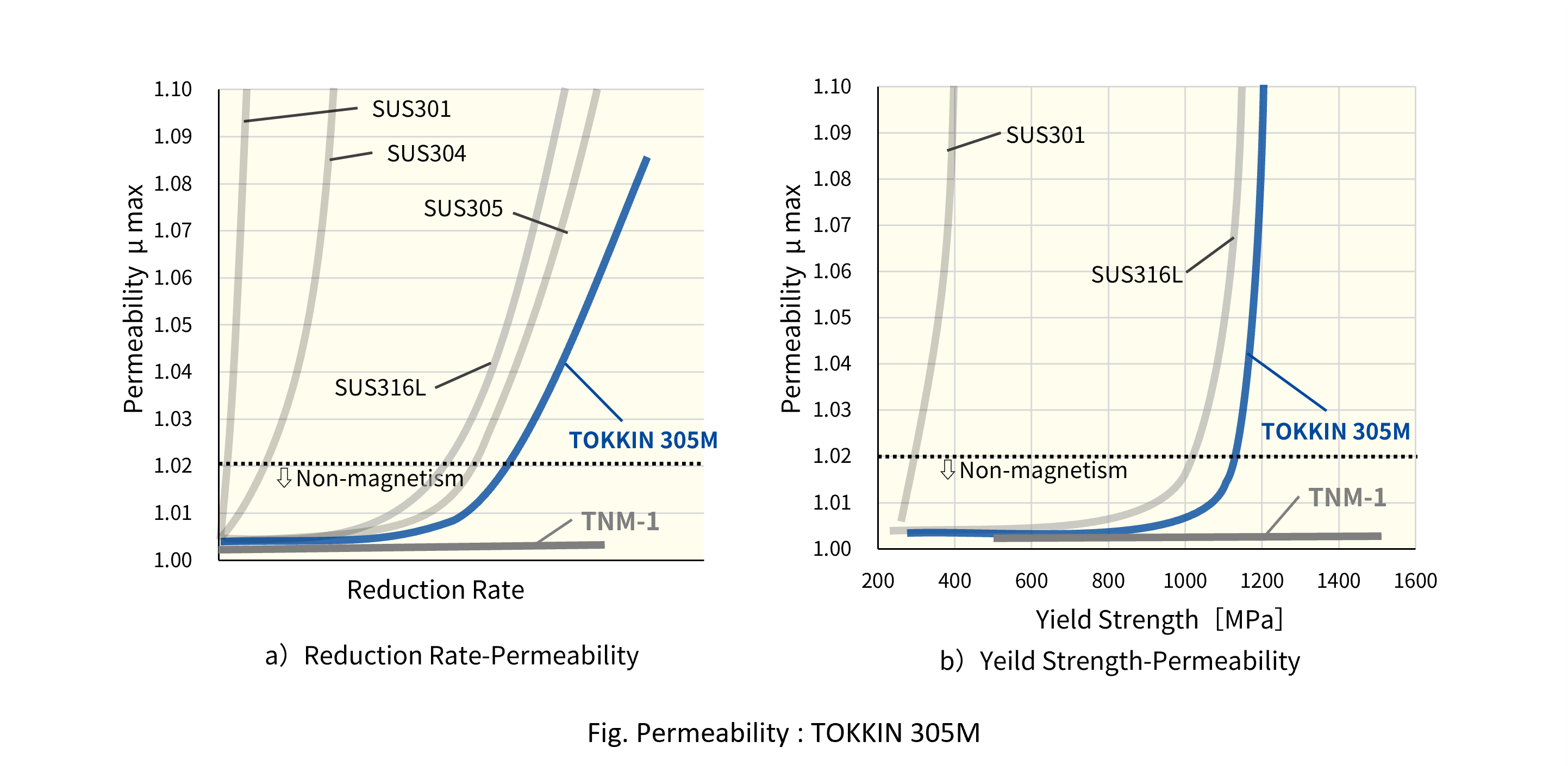

Cold Working and Magnetic Permeability

The figure below shows the correlation between rolling ratio and hardness and magnetic permeability of TOKKIN 305M.

Austenitic stainless steels represented by SUS304 are nonmagnetic in the solution (annealed) condition, but become magnetic when cold rolled,whereas TOKKIN 305M maintains non-magnetic properties due to its high Ni, Mn, and Cr content.

Also, TOKKIN 305M has a higher amount of these elements within the range of JIS SUS 305, so that it can maintain non-magnetic properties better than JIS SUS 305.

Download Technical Data

Related Pages

Non-magnetic Stainless Steels

Stainless steels that are not easily magnetized when a magnetic field is applied is called "non-magnetic stainless steel”.

Stainless Steels Foils (Under t0.10mm)

We offer not only thin stainless steel foils, but also propose the appropriate steel grade and temper depending on specific application and use requirements, such as strength, workablility, magnetism, and corrosion resistance.