Maraging Steels

Maraging Steels

MAS-1 | Maraging Steel

Overview & Features

Because of its high strength, high toughness, and high notch strength, this material is used in aircraft, rockets, missiles, and space development equipment such as satellites.

TOKKIN's MAS-1 raw material is provided by Daido Steel.

Because it achieves over 1960 MPa tensile strength by age-hardening treatment and also has toughness, MAS-1 is also used for watch parts, computer parts, precision springs, diaphragmss, and other parts requiring an extremely high reliability

This is a very expensive material among iron-based alloys because it contains approximately 30% of expensive elements such as Nickel, Cobalt, and Molybdenum.

Main features of MAS-1:

(1) Tensile strength over 1,960 N/mm2MAS-1 can achieve over 1,960 N/mm2 tensile strength through comparatively simple age-hardening treatment.

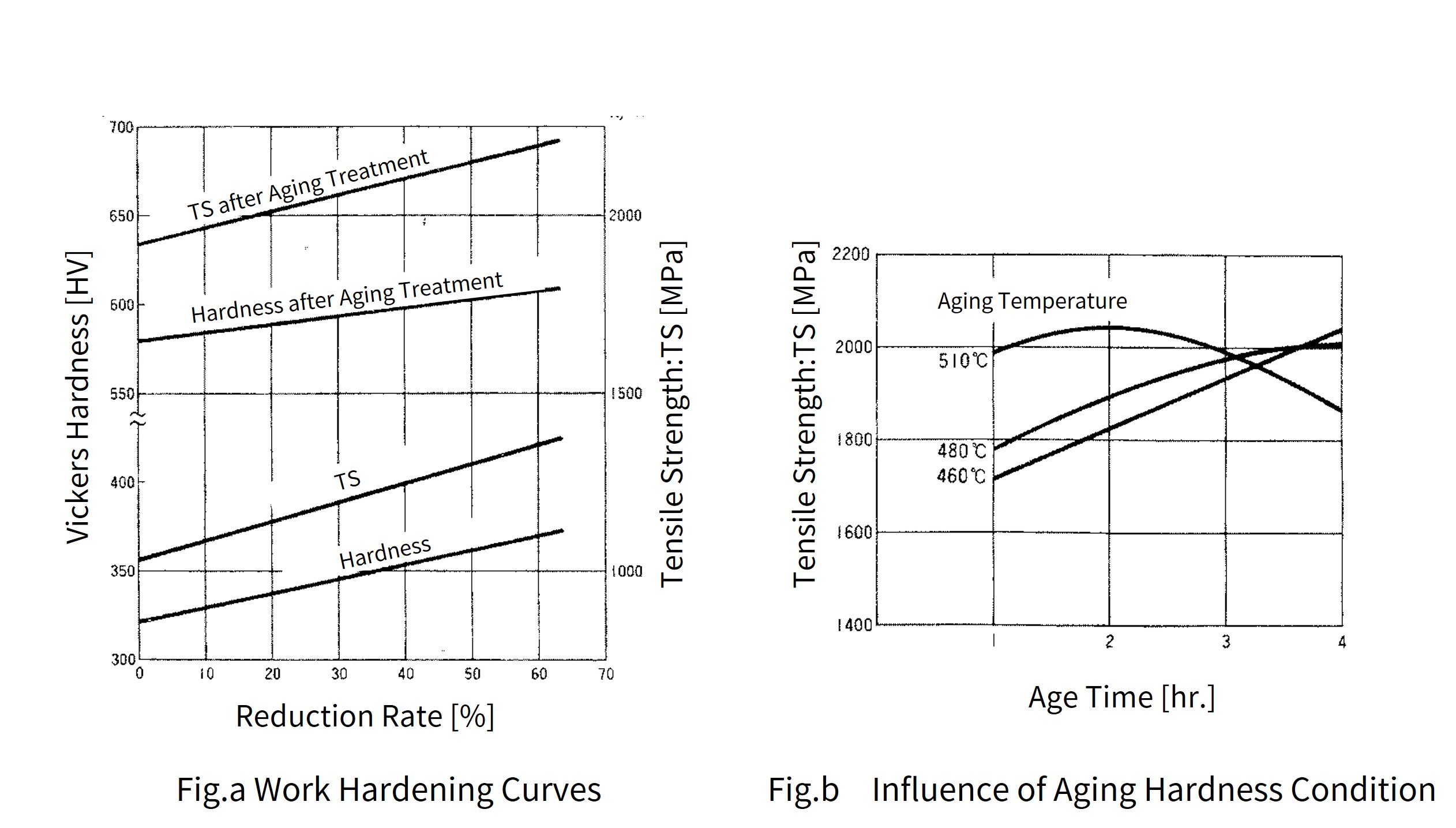

After cold working, tensile strength increases further; for example, tensile strength after age hardening of 50% cold-rolled material reaches over 2,110 N/mm2.

(2) High Strength and Toughness

In addition to high strength, MAS-1 has excellent toughness, and also has high notch and fatigue strength.

(3) Easy processing-Rapid cooling is not required after heat treatment

MAS-1 does not require rapid cooling after age hardening, making it easy to handle and virtually free from distortion due to heat treatment.

(4) Slight Hardening by Cold Working

MAS-1 has a martensitic structure even in the solid solution state, so there is only slight hardening by cold working.

(Increase amount around HV40 with 50% rolling.)

(5) Relatively Good Weldability and Machinability

Examples of Applications

Diaphragms, Valves, Tire Mold Blades, Watch Parts, Printer Parts,Continuously Variable Transmissions for Automobiles, Precision Springs, and Other Parts Requiring High Reliability

Available Shapes

Manufacturable Range (COIL, SHEET)

Thickness

0.050-1.5mm

Width

3.0-300mm

Length

COIL or SHEET less than 2000mm

This is the manufacturing range of coils and sheets we manufacture.

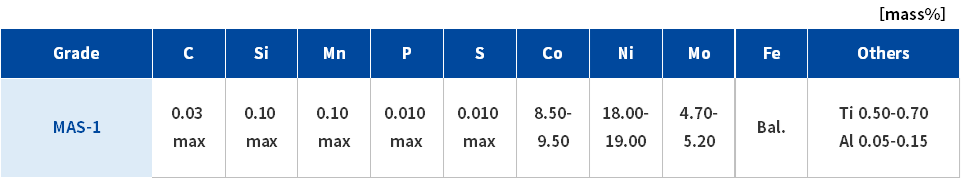

Chemical Composition

Physical Properties

Density

8.02 g/cm³

Specific Heat

335 J/(kg・K)

Electrical Resistivity

60~70 μΩ・cm

Young's Modulus

182 GPa

Thermal Expansion

10.1×10-6/K (20~480℃)

Thermal Conductivity

19.7 W/(m・K) (25℃)

Magnetism

Strong

Mechanical Properties

The table below shows the mechanical properties of the annealed finish and full hardened finish of MAS-1.

Even with annealed finish, it has hardness of 290-340 HV, so it can't be processed like general soft materials.

Heat Treatment

(1) Solution Heat Treatment

Standard solution heat treatment condition is [820-870°C x several minutes to 30 minutes, then cooling].

(2) Age Hardening Heat Treatment

MAS-1 is a steel grade that can be artificially age hardened

Standard age hardening heat treatment condition is [480℃×3 hours] but it is possible to change combinations of temperature and time.

Fig.a below shows mechanical properties resulting from age hardening treatment and cold rolling.

Fig.b below shows the effect of age hardening conditions on tensile strength.

(3) Heat Treatment Atmosphere

Hydrogen or AX gas is appropriate for atmosphere gas in heat treatment.

Corrosion Resistance

Related Pages

Superalloys(Nickel, Cobalt, and Titanium Alloys)

Materials based on Ni, Co, and Ti are superior to stainless steel in terms of corrosion resistance and heat resistance. In addition to cold-rolled strips manufactured by our company, we also provide thick plates, wires, bars, and ultra-thin pipes sourced from domestic and overseas partner companies for you.

Stainless Steels for Springs

This materials are possible to increase their hardness by rolling, they can be used as spring parts.

High-Strength, High-Ductility

JIN™

"TOKKIN's uniquely designed production method for JIN™ brings you a material that combines high strength and excellent workability that cannot be obtained with ordinary manufacturing methods. The balance of Yield stress (YS) exceeds 35,000 MPa x Elongation (EL) is among the highest in the world."