Nickel, Cobalt, and Titanium Alloys

Cobalt Alloys

MP35N® – UNS R30035 – ASTM F562 | Cobalt Alloy

Overview & Features

It has high resistance to stress corrosion cracking caused by sulfides and shows excellent performance in natural gas drilling in high hydrogen sulfide atmospheres. In seawater, it has the highest resistance to crevice corrosion, stress corrosion and pitting.

Additionally, this is often used in medical applications such as implants and dental instruments because of its high biocompatibility. It is also used in temperatures ranging from cryogenic to 454°C.

TOKKIN supplies a wide variety of shapes, including foils and sheets, as well as ultrafine pipes, rods, and plates.

*MP35N® is a registered trademark of SPS Technologies, Inc.

Examples of Applications

Implants, Dental Instruments, Offshore plants, Aerospace parts

Available Shapes

For inquiries regarding procurement items (Pipes, bars, Wires etc.), please contact us.

Manufacturable Range (COIL, SHEET)

Thickness

0.010-2.0mm

Width

3.0-300mm

Length

COIL or SHEET less than 2000mm

This is the manufacturing range of coils and sheets we manufacture.

Standards

Standards are listed as equivalent or similar to our materials, so please use them as a reference.

UNS

ASTM

R30035

F562

ISO

5832-6

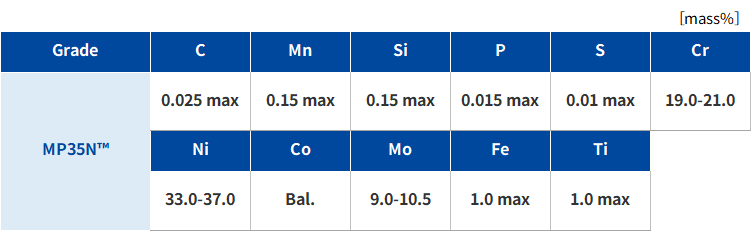

Chemical Composition

Physical Properties

Density

8.43 g/cm³

Electrical Resistivity

103 μΩ・cm

Young's Modulus

Annealed condition: 232.8 GPa (26℃)

Thermal Expansion

12.8×10-6/K(21~93℃)

Thermal Conductivity

11.2 W/(m・K) (21℃)

Melting Range

1315-1450 ℃

Magnetism

Non-magnetism *Permeability: 1.0009(21℃)

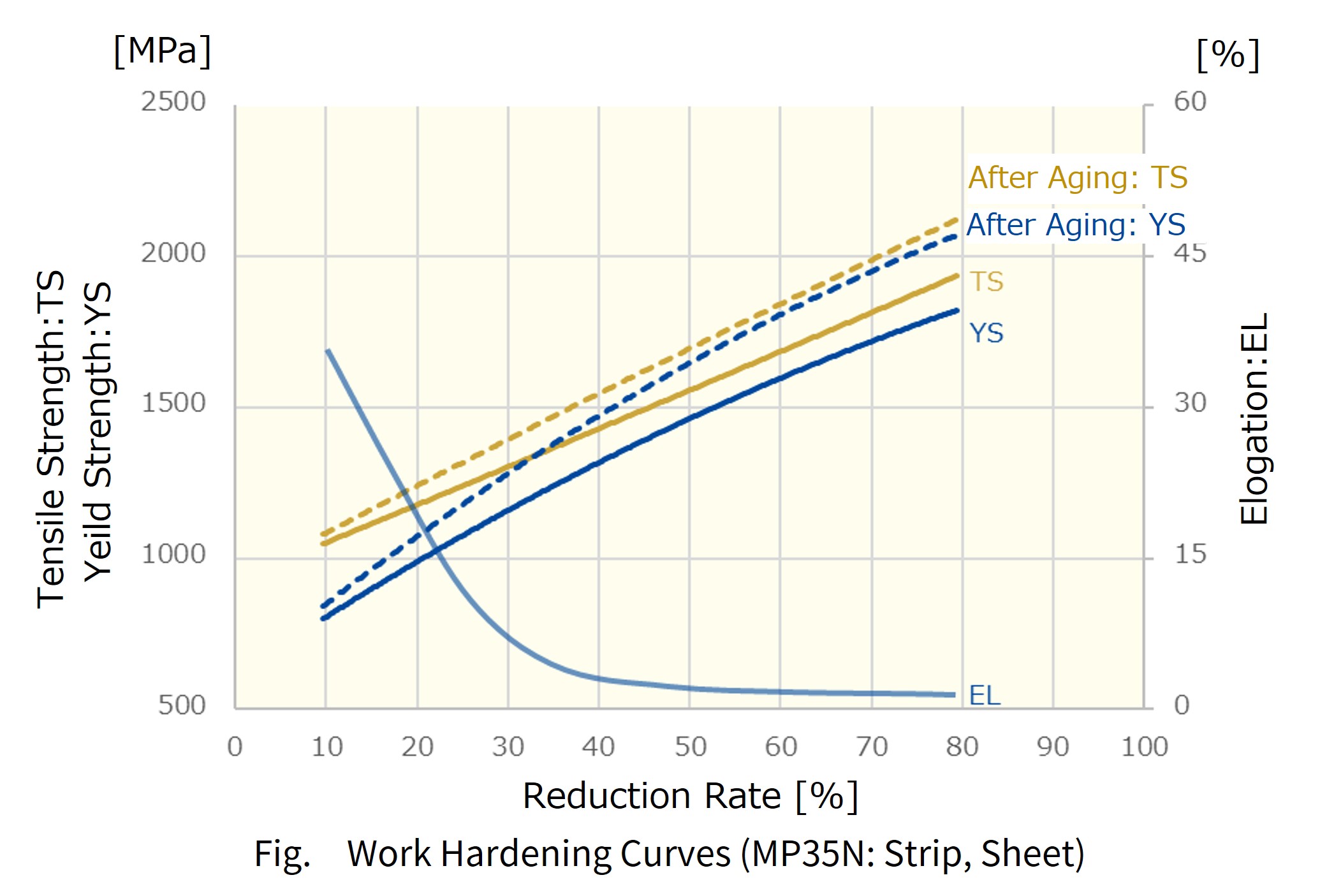

Mechanical Properties

The table below shows correlations of rolling ratio and tensile strength.

Its strength can be improved by age-hardening treatment(heat treatment).

Heat Treatment

■ Annealing Condition

[Heating at 1040~1100℃ → cooling]

■ Aging Treatment

To obtain optimum mechanical properties, aging treatment is performed [holding at 550-600℃ for 4 hours → air cooling] after cold working.

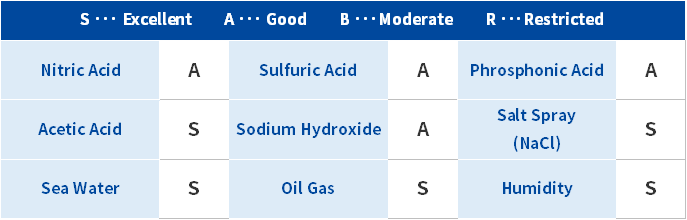

Corrosion Resistance

Download Technical Data

Related Pages

Superalloys(Nickel, Cobalt, and Titanium Alloys)

Materials based on Ni, Co, and Ti are superior to stainless steel in terms of corrosion resistance and heat resistance. In addition to cold-rolled strips manufactured by our company, we also provide thick plates, wires, bars, and ultra-thin pipes sourced from domestic and overseas partner companies for you.

Metal Foils (Under t0.10mm)

We can produce foil materials in all the materials we manufacture, from stainless steel, low carbon steel, high carbon steel, and other steel materials to nonferrous metals such as nickel alloys, cobalt alloys, and copper alloys.

Stainless Steels for Springs

This materials are possible to increase their hardness by rolling, they can be used as spring parts.