Edge Treatment (Round edge, Debarred edge)

- HOME

- SEARCH MATERIALS

- Processing

- Processing Service

- Edge Treatment (Round edge, Debarred edge)

Processing

Processing Service

Edge Treatment (Round edge, Debarred edge)

Overview & Features

This process enables applications where the material width and edge are used as is.

Smoothing the edge also prevents fatigue failure from the width direction, leading to improved spring durability.

※1 Slit Edge: Slitting only (standard specs)

※2 Mill Edge: Removing burrs generated by slitting with file

※3 Round Edge: Processing burrs generated by slitting as well as the shear drop side.

(You can choose between arc-shaped rounded edges or rounded corners.)

Examples of Applications

Springs, Quartz Crystals, Industrial Cutting Tools, Knitting Needles, Tape Measures, Pen Clips, Design Parts, Ride Door Springs

Available Shapes

Manufacturable Range (COIL, SHEET)

Thickness

Debarred edge: 0.10-1.00mm

Round edge/Angle edge: 0.15-1.5mm

Width

Debarred edge: 5.0-70.0mm

Round edge/Angle edge: 8.0-40mm

Depends on material grade and specifications.Please contact us for more details.

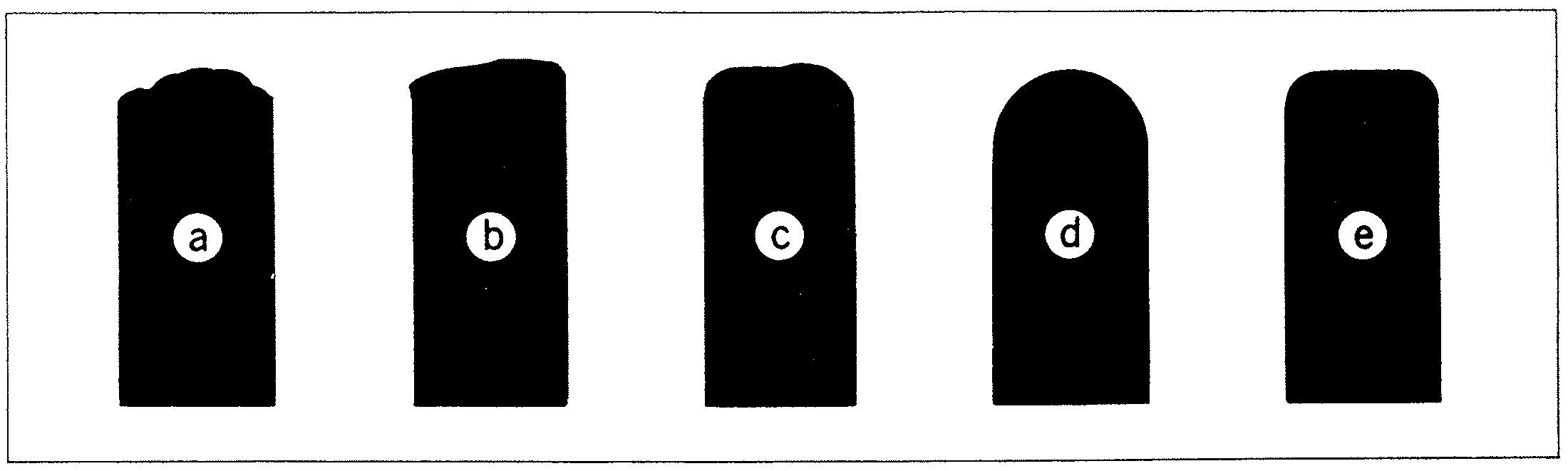

Types of Edge

We supply following five kinds of edges.

a) Mill edge …Edge condition after rolling

b) Slit edge …Edge condition after slit-off(general edge)

c) Deberred edge …Edge condition after slit-off and removing burr

d) Round edge …Edge condition after slit-off and round processing

e) Angle edge …Edge condition after slit-off and angle processing

Related Pages

Slitting (Processing Service)

We accept contract processing of slit only, starting from one coil.