Slitting (Processing Service)

- HOME

- SEARCH MATERIALS

- Processing

- Processing Service

- Slitting (Processing Service)

Processing

Processing Service

Slitting (Processing Service)

Overview & Features

We guarantee high slitting quality by using our technology and know how developed through years of manufacturing experience, and cutting machines suited to the material.

Feature of our slitting service:

(1) Over 60 different materials can be prpcessed.(2) We promise high quality with the latest slitting machines.

(3) State-of-the-art backup system to keep delivery on time.

Please feel free to use our slitting service in the following situations:

・To re-slit only one coil.

・To slit multiple narrow coils from wide coil.

・To request slitting of special products such as plated materials and metal foils, etc.

Available Shapes

Finished ID: φ300mm, 400mm, 500mm

Unit weight: 5.0kg/mm max

Others: Inner core, Paper interleave, Packing etc. available

Manufacturable Range (COIL, SHEET)

Thickness

0.010-3.0mm

Width

3.0-330mm

Depends on material grade and specifications.Please contact us for more details.

Examples of Slittable Materials

Basically, if it is a metal strip (obi), it can be slit.

Materials(Example)

・Iron and Steels(anneled materials~rolled materials)

・Stainless Steels(anneled materials~full hardened materials)

・Non-ferrous metals(Copper and copper alloys, nickel alloys, aluminum alloys, titanium alloys, etc.)

Special Products

・Foil materials with thickness of under 0.10mm

・Plating

・Clad metals

・Materials which are easy to rust such as iron and steels.(Oil soaking and rustproof paper packaging are available after slitting)

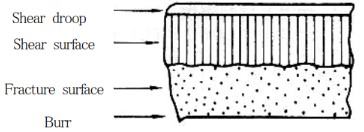

Also,as shown in the figure below, the cut surface will be in the following states: shear, shear, fracture, and burr.

We slit with the best condition based on our records, but if you have any preferece, please request it to the sales representative beforehand.

Slit Quality

Please refer to the the following pages for dimensional tolerances.

Related Pages

Re-rolling (Processing Service)

We offer contract rolling (rerolling) of materials provided by our customers, as well as rerolling of market materials.

Edge Treatment (Round edge, Debarred edge)

Edge treatment is a further processing applied to the normal Slit Edge and can be delivered with "Debarred Edge" to remove burrs or "Round Edge" to round the edge.