NCH-2 | Electrical Heating Alloys

- HOME

- SEARCH MATERIALS

- Resistance Alloys / Electrical Heating Alloys

- Electrical Heating Alloys

- NCH-2 | Electrical Heating Alloys

Resistance Alloys / Electrical Heating Alloys

Electrical Heating Alloys

NCH-2 | Electrical Heating Alloys

Overview & Features

Examples of Applications

Heaters (surface heating element), E-cigarettes, Sealers

Available Shapes

This item is available in wire form only.

Please contact us for detailed specifications.

Standards

Standards are listed as equivalent or similar to our materials, so please use them as a reference.

JIS

NCHRW2 (C2520)

DIN

NiCr6015, 2.4867

GB

Cr15Ni60

Other names

ISA-CHROM 60

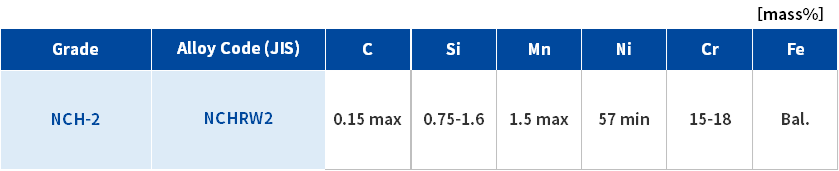

Chemical Composition

Physical Properties

Density

8.3 g/cm³

Volume Resistivity

1.12 μΩ・m

Temperature Coefficient of Resistance

50 ppm/K (23-100℃)

Maximum Ambient Temperature

1000℃

Magnetism

Non-magnetism

Mechanical Properties

The hardness of the annealed finish is [under 250 HV ], but we can provide hard materials upon your request.

*In the case of ultra-thin foil, soft materials such as annealed and 2B finish may not be available due to concerns about defects (folding, wrinkling, etc.).

Related Pages

Resistance Alloys

We supply various types of resistance alloys: "Electrical Resistance Alloys" to control electricity and electric current, and "Electrical Heating Alloys" that utilize the property of metals to generate heat due to electric resistance. We control Temperature Coefficient of Resistance (TCR), conductor resistance, and guarantee thickness with high precision.

Metal Foils (Under t0.10mm)

We can produce foil materials in all the materials we manufacture, from stainless steel, low carbon steel, high carbon steel, and other steel materials to nonferrous metals such as nickel alloys, cobalt alloys, and copper alloys.