High-precision thickness materials (t0.010mm - 2.0mm)

- HOME

- SEARCH MATERIALS

- Unique Technologies/High Performance Materials

- High Performance Materials

- High-precision thickness materials (t0.010mm - 2.0mm)

Unique Technologies/High Performance Materials

High Performance Materials

High-precision thickness materials (t0.010mm - 2.0mm)

Overview & Features

We produce wide range of thicknesses from 0.010 to 2.00 mm with precise thickness tolerances that cannot be manufactured by JIS or other companies. We guarantee high-precision thickness with little variation over the entire length of the hoop.

The following advantages are expected by using high precision thickness materials.

(1) Reduction of Post-Processing such as PolishingBy reducing the post-processing required for thickness adjustment, customer can easily manage quality, shorten lead time, and reduce costs.

(2) Improves Quality by Stabilizing Part Dimensions

By using materials with less variation in thickness, it is possible to reduce the variation in part dimensions after stamping or drawing and improve product yields and sorting time.

(3) Reduces Variations in Strength and Electrical Resistivity

High-precision thickness products improve the quality of parts by reducing variations in mechanical strength, conductor resistance, etc., which are affected by material cross-sectional area.

Examples of Applications

Shims, Thickness Gauges, Spacers, Knitting Machine Parts, Fineblanking Parts, Clock Gears, Sensor Caps, Springs

Available Shapes

Manufacturable Range (COIL, SHEET)

Thickness

0.010-2.0mm

Width

3.0-300mm

Length

COIL or SHEET less than 2000mm

This is the manufacturing range of coils and sheets we manufacture.

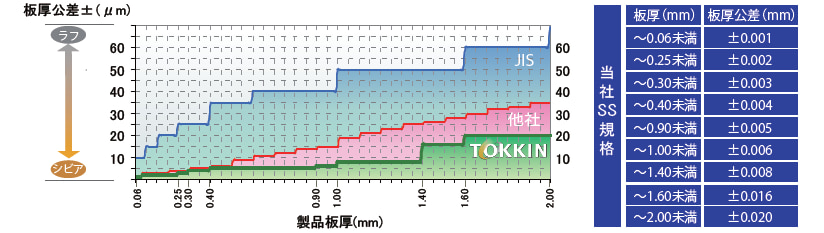

Comparison of thickness tolerance (our company vs. other company vs. JIS standards)

The comparison of the tolerances of our SS standard, other companies' special standards, and JIS standards is shown in the figure below.

Please refer to this page for specific thickness tolerances.

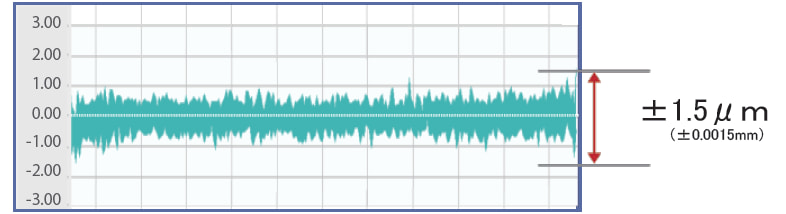

Thickness Chart in longitudinal direction ( Actual measured value for reference )

Our thickness chart (example of actual measurement) for a plate thickness of 0.20 mm is shown below.

In this example, the variation is ±1.5 μm (±0.0015 mm) over the entire length.

Related Pages

[Equipments] Cold rolling

Cold rolling is one of a plastic forming process which room-temperature material is passed between rotating rolls and stretched thinner by applying pressure at the top and bottom.

[Technology] Dimensional Tolerance

Various dimensional tolerances of the products we manufacture.