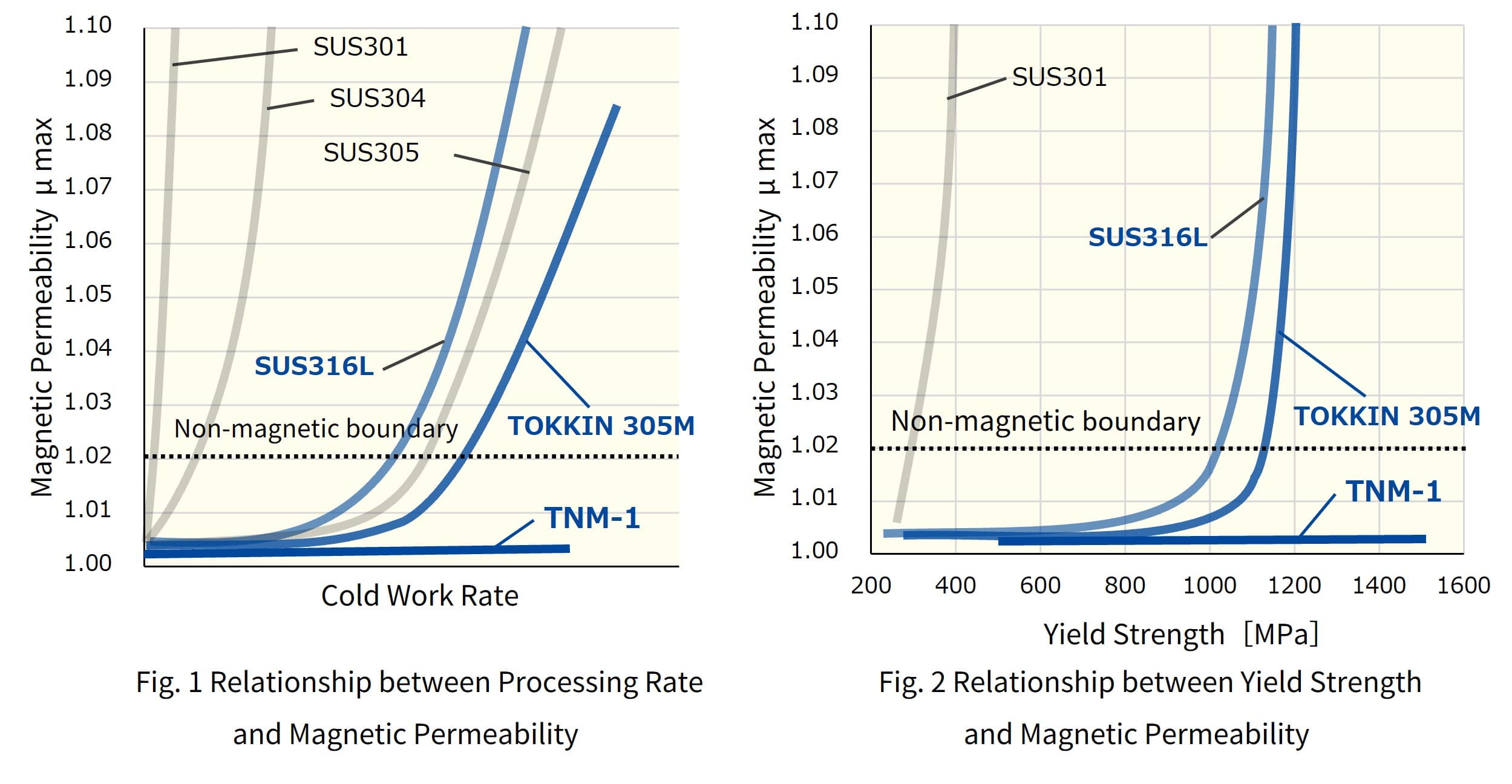

SUS304, a representative austenitic stainless steel, is nonmagnetic in the solution heat-treated state, but it becomes magnetic due to martensitic transformation after cold working.Therefore, there were challenges such as keeping the processing rate low and sacrificing strength in order to maintain non-magnetic properties.

As Non-magnetic stainless steels are grades that are adjusted so that martensite is not induced (or is not easily induced) by cold working, it can maintain its nonmagnetic properties even after machining. We will propose steel grades according to your usage conditions, such as processing method and required non-magnetic level.

Electromagnetic Shielding, Vibration Motors, Camera Modules, FPCs, Communication Equipment Components, Medical Devices, Indwelling Needles

Thickness : 0.010mm-2.0mm *Availability may vary by steel grade.

Width : 3.0mm-300mm *Contact Sales if your desired values is over 300mm.

Length : COIL or SHEET less than L2000mm

Please scroll horizontally to view.

| Type | Grade | Features | High Strength | Non-Magnetic | Wokability | Corrosion Resistance |

|---|---|---|---|---|---|---|

| Non-Magnetic Stainless Steel | TNM-1™ [TOKKIN Original Product] |

A steel grade whose composition has been adjusted to maintain nonmagnetic properties even at extremely high working rates. Extremely high strength of 500 HV can be obtained, making it ideal for applications that require high non-magnetic properties and high springiness. Soft materials can also be drawn. | S | S | A | A |

| TOKKIN 305M [TOKKIN Original Product] |

This is a steel grade in which the austenite phase is stabilized by increasing the content of nickel, manganese, chromium, etc. in SUS304 (18Cr-8Ni), and is hardly magnetized even after cold rolling. TOKKIN 305M is more stable than general SUS305 because these elements are adjusted to a higher level within the range of JIS standard SUS305. It also has excellent workability and corrosion resistance due to its high nickel content. |

A* | A* | A | A | |

| SUS316L | Among general-purpose stainless steels, it is often used for applications that require non-magnetic properties because of its slow martensitic transformation during processing. However, it tend to gain magnetism (measured as “magnetic permeability”) when they are work-hardened (machined, formed, stamped, bent, etc.). Its high nickel content and addition of molybdenum provide excellent workability and corrosion resistance. |

B* | A* | A | S |

*Please note that weak magnetism occurs as the processing rate increases.

Please scroll horizontally to view.

[mass%]

| Type | Grade | C | Si | Mn | P | S | Cr | Ni | Mo | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Non-Magnetic Stainless Steel | TOKKIN 305M | 0.07-0.09 | 0.60-1.00 | 1.40-1.80 | 0.045 max | 0.030 max |

18.00-19.00 | 12.00-13.00 | - | Bal. |

| SUS305 (JIS) |

0.12 max |

1.00 max |

2.00 max |

0.045 max | 0.030 max |

17.00-19.00 | 10.50-13.00 | - | Bal. | |

| SUS316L | 0.030 max |

1.00 max |

2.00 max |

0.045 max | 0.030 max |

16.00-18.00 | 12.00-15.00 | 2.00-3.00 | Bal. |

Please scroll horizontally to view.

| Typical Value | Before Processing (Skin-passed material) | Maximum Strength | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Permeability μ max |

Hardness [HV] |

Tensile Strength [MPa] |

Yield Stress [MPa] |

Elongation [%] |

Permeability μ max |

Hardness [HV] |

Tensile Strength [MPa] |

Yield Stress [MPa] |

Elongation [%] |

|

| TNM-1™ | 1.003 | 260 | 920 | 570 | 48 | 1.003 | 510 | 1730 | 1700 | 0.1 |

| TOKKIN 305M | 1.004 | 190 | 700 | 420 | 50 | Over 1.2 | 400 | 1220 | 1200 | 0.3 |

| SUS316L | 1.004 | 185 | 660 | 420 | 50 | Over 1.2 | 380 | 1200 | 1180 | 0.3 |

We can make it to foils (less than 0.10 mm thick) in all the stainless steels we manufacture.

Austenitic materials are nonmagnetic in the solution heat-treated state and become magnetic when cold worked. However, TOKKIN 305M is a non-magnetic stainless steel designed to reduce this tendency.

This steel type is specifically designed with adjusted composition to maintain non-magnetism even at extremely high processing rates.

This material has a lower carbon content than SUS316, and has improved drawability and intergranular corrosion resistance.