Stainless Steels

Ferritic

TDS-1 | Soft Magnetic Stainless Steel

Overview & Features

It has high magnetic flux density and low coercive force, making it excellent in magnetization, demagnetization, and magnetic shielding properties. It can be used as electromagnetic stainless steel by applying magnetic annealing.

Main features of TDS-1:

(1) Electromagnetic Stainless SteelIt can be used as an electromagnetic stainless steel by magnetic annealing.

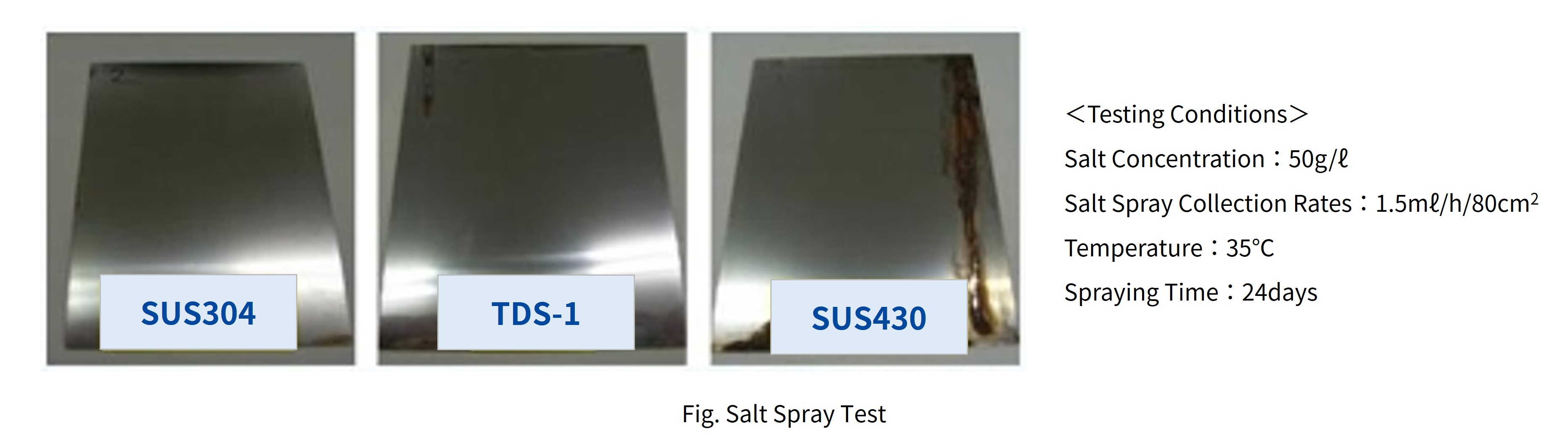

(2) Corrosion Resistance

TDS-1 has a better corrosion resistance than SUS430.

(3) Conductivity is nearly the same as 42 Alloy,

The coefficient of thermal expansion of TDS-1 is about half of 42Ni, though the conductivity is the same. Switching from 42Ni can reduce costs by as much as 50%.

(4) Extensive installation experiences with TDS-1 replacing other grades

We have abundant experience of introducing TDS-1 to our customers to replace their current steel grades such as 42Ni, phosphor bronze, SUY, Permalloy, etc.

We can also manufacture foils below 0.10 mm in thickness and in small lots.

Examples of Applications

Shielding Cases, Electromagnetic Shields, Capacitors, Actuators

Available Shapes

Manufacturable Range (COIL, SHEET)

Thickness

0.030-2.0mm

Width

3.0-300mm

Length

COIL or SHEET less than 2000mm

This is the manufacturing range of coils and sheets we manufacture.

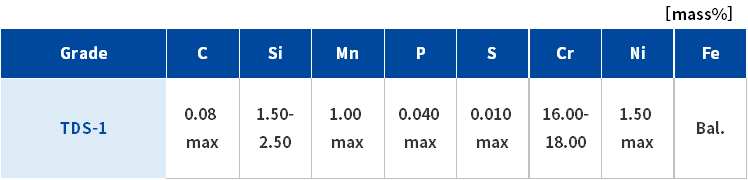

Chemical Composition

Physical Properties

Density

7.73 g/cm³

Electrical Resistivity

70 μΩ・cm

Young's Modulus

206 GPa

Thermal Expansion

11.3×10-6/K(0~100℃)

Thermal Conductivity

25.1 W/(m・K) (100℃)

Melting Range

1460-1500 ℃

Magnetism

Soft Magnetism

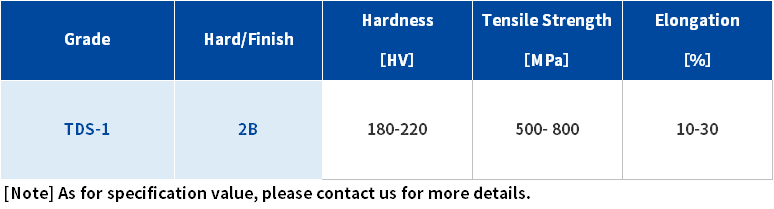

Mechanical Properties

Corrosion Resistance

The corrosion resistance is equivalent to or more than SUS430 and higher than soft magnetic iron steels and Permalloy.

In general environments, it can be used without plating or other surface treatment.

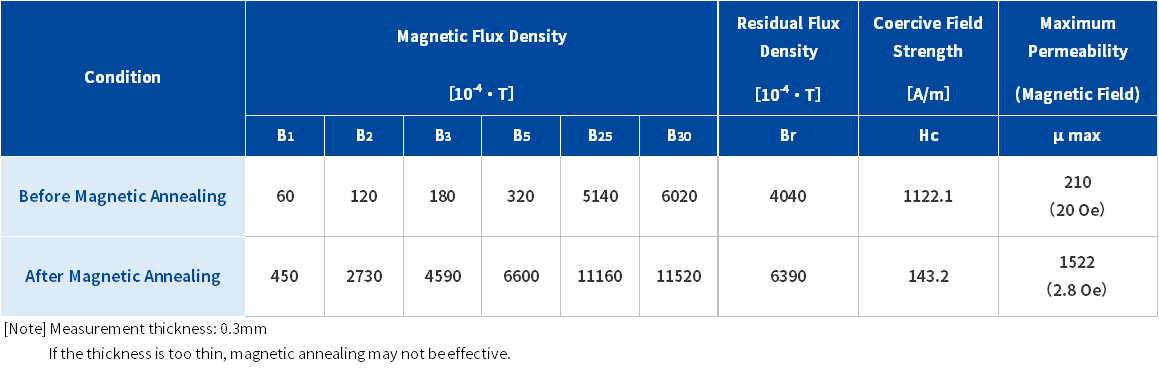

Magnetic Properties

By performing magnetic annealing, it has better maximum permeability and coercive force than SUS430, resulting in a high response to external magnetic fields.

Download Technical Data

Related Pages

Soft Magnetic Materials

Soft magnetic material is easily magnetized when a magnetic field is applied, but returns to its original state when the magnetic field is removed. We also manufacture our original steel grades such as electromagnetic stainless steel with corrosion resistance and extremely high strength.

Stainless Steels

Stainless steel is an alloy of iron (Fe) with at least 10.5% chromium (Cr) and is used in a wide range of applications because it has good properties in terms of corrosion resistance, strength, workability, and heat resistance.