Introduction to the High Carbon Steels.

Carbon content greatly affects hardenability, wear resistance, and workability.

Click on any particular grade to see the details. Please refer to the table of contents below to see the properties of each steel.

Please scroll horizontally to view.

| Type | Grade | Description *Links are to related pages |

|---|---|---|

| Razor Steel |

TE-2 |

Razor Steel has improved hardenability by adjusting the composition and strictly controlling manufacture history, and have finer carbides to improved sharpness and wear resistance. It is used in razor blades replacement, long blades, high-grade blades, etc. |

| Carbon Tool Steel *Reference Standards |

SK120(SK2) SK75(SK6) SK65(SK7) |

Among special cold-rolled strips, carbon tool steel is the most widely used for its workability, hardenability, product performance, price, etc. Applications range from hard items such as industrial knives, cutting tools, and tools to items requiring elasticity and toughness such as springs, knitting needles, horns, tape measures, and washers. |

| Carbon Steel *Reference Standards |

S60C S55C S15C |

Carbon steel has a lower carbon content than carbon tool steel and is less restrictive on impurities, making it suitable for general applications that require a certain degree of strength and toughness. Low carbon materials have better workability in raw materials, but are prone to uneven hardening, so they are used for structural parts, springs, washers, clutch parts, thompson blades, bearing parts, etc. for office machines, electrical equipment, and machinery. |

| Alloy Tool Steel *Reference Standards |

SKS2 SKS7 |

SKS2 and SKS7 are high-carbon steels with tungsten and chromium added to disperse fine hard double carbides. It has excellent abrasion resistance and high-temperature strength and is used for cutters, hacksaws, metal band saws, etc. Also, SKS51 is a material with increased toughness due to the addition of nickel and chromium and is used in hand saws, cutters, etc. |

| Steel for Knitting Needles, Textile Machinery High-cleanliness Steel |

M1 M2 MB-1 |

General steel made under normal manufacturing conditions will inevitably contain some non-metallic inclusions during its steelmaking process, which can often be a problem in applications where high reliability is required. These steels are based on SK95 (SK4) with improved wear resistance and heat treatability, and are suitable for applications where longevity and fatigue properties are important. In MB-1, a special refining process is added to the conventional steelmaking process to reduce inclusions, resulting in a high cleanliness steel. |

| Chrome Molybdenum Steel *Reference Standards |

SCM415 | Chrome-molybdenum steel is a typical structural alloy that can be hardened and tempered to achieve medium strength and toughness. These materials have low hardness and are highly workable. In addition, due to the effects of the alloy components, it has good hardenability, and even if the cooling rate is somewhat slow, it will harden and the occurrence of distortion will be reduced. SCM415 is a case-hardening steel, typically carburized to harden the surface. It is used for office machines, electricity, mechanical parts, thomson blades, chain parts, etc. |

Approximate rolling reduction rate of each temper / finish is as follows.

| Temper/Finish | Rolling Reduction Rate |

|---|---|

| Annealed | 0% |

| Skin Passed | Under 5% |

| Rolled(As-Rolled) | 15-40% |

| Full Hard | Over 35% |

Approximate strength of each steel grade by temper/finish is shown in the table below. (Steel grades not supplied by our company are also listed for reference.)

Please scroll horizontally to view.

| Grade | Temper/Finish | Hardness Test | Tensile Test | ||

|---|---|---|---|---|---|

| [HV] | Tensile Strength [N/m㎡] |

Elongation [%] |

|||

| TE-2 SK120(SK2) |

Annealed | 170~210 | 520~685 | 20~32 | |

| Skin Passed | 190~230 | 570~715 | 10~28 | ||

| Rolled | 250~290 | 735~980 | 2~15 | ||

| Full Hard | 280~320 | 835~1080 | 1~3 | ||

|

Related Page Materials for Industrial Knives and Blades │ TE-2, SK95, SK85, SUS420J2 |

|||||

| SK95(SK4) M1 M2 MB-1 |

Annealed | 160~200 | 490~645 | 24~35 | |

| Skin Passed | 175~215 | 540~695 | 12~32 | ||

| Rolled | 245~285 | 725~970 | 2~15 | ||

| Full Hard | 270~310 | 825~1040 | 1~4 | ||

|

Related Page Materials for Knitting Needles and Textile Machinery Parts│MB-1, M1, M2 |

|||||

| SK85(SK5) | Annealed | 150~190 | 460~625 | 26~37 | |

| Skin Passed | 170~210 | 510~685 | 15~35 | ||

| Rolled | 240~280 | 725~930 | 3~16 | ||

| Full Hard | 260~300 | 805~1000 | 1~5 | ||

| SK75(SK6) S70C |

Annealed | 145~185 | 440~615 | 27~38 | |

| Skin Passed | 160~200 | 490~665 | 15~35 | ||

| Rolled | 235~275 | 715~920 | 3~16 | ||

| Full Hard | 255~295 | 795~990 | 1~5 | ||

| SK65(SK7) S60C S55C S50C S45C S20C S15C |

Annealed | 140~180 | 410~610 | 28~39 | |

| Skin Passed | 155~195 | 460~655 | 16~36 | ||

| Rolled | 230~270 | 705~900 | 3~17 | ||

| Full Hard | 250~290 | 775~970 | 1~5 | ||

| SKS2 | Annealed | 190~230 | 615~715 | 20~30 | |

| Full Hard | 280~320 | 835~1080 | 1~3 | ||

| SKS7 | Annealed | 200~240 | 645~735 | 20~28 | |

| Full Hard | 300~340 | 880~1125 | 1~3 | ||

| SCM415 | Annealed | 125~165 | 335~540 | 28~50 | |

| Full Hard | 200~240 | 655~735 | 1~8 | ||

Please scroll horizontally to view.

| Type | Grade | Chemical Compositions[mass%] | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cr | Ni | Fe | Cu | Others | ||

| Razor Steel | TE-2 | 1.20-1.30 | 0.15-0.35 | 0.35 max |

0.030 max |

0.020 max |

0.30- 0.50 | 0.25 max |

Bal. | 0.25 max |

- |

| SKS81M | 1.10- 1.30 | 0.35 max |

0.50 max |

0.030 max |

0.030 max |

0.20- 0.50 | 0.25 max |

Bal. | 0.25 max |

- | |

| Carbon Tool Steel | SK120M (SK2M) |

1.15-1.25 | 0.10-0.35 | 0.10-0.50 | 0.030 max |

0.030 max |

0.30 max |

0.25 max |

Bal. | 0.25 max |

- |

| SK95M (SK4M) |

0.90-1.00 | 0.10-0.35 | 0.10-0.50 | 0.030 max |

0.030 max |

0.30 max |

0.25 max |

Bal. | 0.25 max |

- | |

| SK85M (SK5M) |

0.80-0.90 | 0.10-0.35 | 0.10-0.50 | 0.030 max |

0.030 max |

0.30 max |

0.25 max |

Bal. | 0.25 max |

- | |

| SK75M (SK6M) |

0.70-0.80 | 0.10-0.35 | 0.10-0.50 | 0.030 max |

0.030 max |

0.30 max |

0.25 max |

Bal. | 0.25 max |

- | |

| SK65M (SK7M) |

0.60-0.70 | 0.10-0.35 | 0.10-0.50 | 0.030 max |

0.030 max |

0.30 max |

0.25 max |

Bal. | 0.25 max |

- | |

| Steel for Knitting Needles, Textile Machinery High-cleanliness Steel |

MB-1 | 0.95-1.05 | 0.15-0.35 | 0.50-0.70 | 0.010 max |

0.003 max |

0.30- 0.45 | - | Bal. | - | V 0.050 max Mo 0.050 max |

| M2 | 0.95-1.05 | 0.15-0.35 | 0.60-0.80 | 0.026 max |

0.010 max |

0.35- 0.45 | - | Bal. | - | Mo 0.02-0.03 |

|

| M1 | 0.90-1.00 | 0.15-0.35 | 0.35-0.50 | 0.030 max |

0.007 max |

0.20- 0.30 | - | Bal. | - | Mo 0.01-0.02 |

|

| Alloy Tool Steel | SKS7M | 1.10-1.20 | 0.35 max |

0.50 max |

0.030 max |

0.030 max |

0.20- 0.50 | 0.25 max |

Bal. | 0.25 max |

W 2.00-2.50 |

| SKS2M | 1.00-1.10 | 0.35 max |

0.80 max |

0.030 max |

0.030 max |

0.50- 1.00 | 0.25 max |

Bal. | 0.25 max |

W 1.00-1.50 |

|

| SKS51M | 0.75-0.85 | 0.35 max |

0.50 max |

0.030 max |

0.030 max |

0.20- 0.50 | 1.30-2.00 | Bal. | 0.25 max |

- | |

| Carbon Steel | S70CM | 0.65-0.70 | 0.15-0.35 | 0.60-0.90 | 0.030 max |

0.035 max |

0.20 max |

0.20 max |

Bal. | 0.30 max |

- |

| S60CM | 0.55-0.60 | 0.15-0.35 | 0.60-0.90 | 0.030 max |

0.035 max |

0.20 max |

0.20 max |

Bal. | 0.30 max |

- | |

| S55CM | 0.52-0.58 | 0.15-0.35 | 0.60-0.90 | 0.030 max |

0.035 max |

0.20 max |

0.20 max |

Bal. | 0.30 max |

Ni±Cr 0.35 max |

|

| S50CM | 0.47-0.53 | 0.15-0.35 | 0.60-0.90 | 0.030 max |

0.035 max |

0.20 max |

0.20 max |

Bal. | 0.30 max |

Ni±Cr 0.35 max |

|

| S45CM | 0.42-0.48 | 0.15-0.35 | 0.60-0.90 | 0.030 max |

0.035 max |

0.20 max |

0.20 max |

Bal. | 0.30 max |

Ni±Cr 0.35 max |

|

| S20CM | 0.18-0.23 | 0.15-0.35 | 0.30-0.60 | 0.030 max |

0.035 max |

0.20 max |

0.20 max |

Bal. | 0.30 max |

Ni±Cr 0.35 max |

|

| S15CM | 0.13-0.18 | 0.15-0.35 | 0.30-0.60 | 0.030 max |

0.035 max |

0.20 max |

0.20 max |

Bal. | 0.30 max |

Ni±Cr 0.35 max |

|

| Chrome Molybdenum Steel | SCM415M | 0.13-0.18 | 0.15-0.35 | 0.60-0.85 | 0.030 max |

0.030 max |

0.90- 1.20 | 0.25 max |

Bal. | 0.30 max |

Mo 0.15-0.30 |

| Type | Grade | C | Si | Mn | P | S | Cr | Ni | Fe | Cu | Others |

| Chemical Compositions[mass%] | |||||||||||

Please scroll horizontally to view.

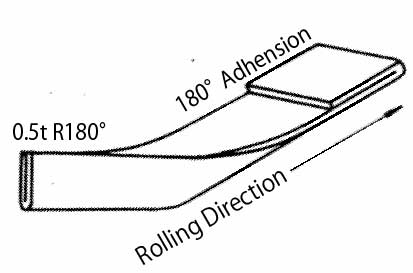

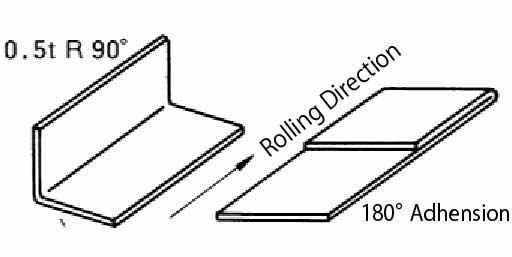

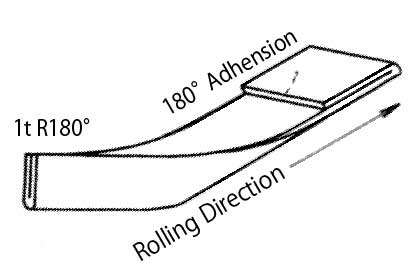

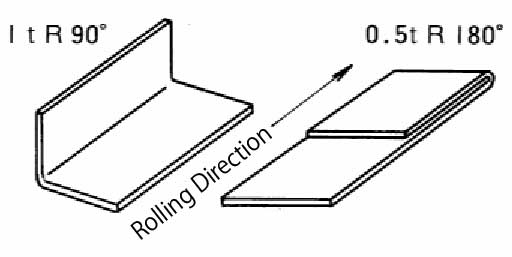

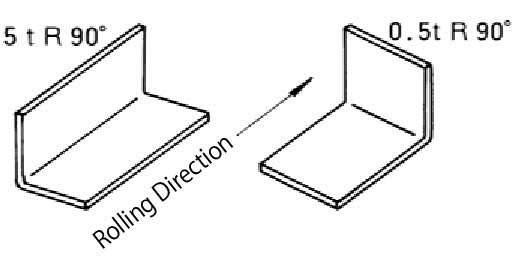

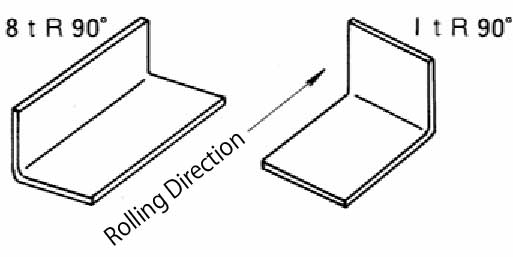

| Temper/Finish | Thickness:below 1mm | Thickness:over 1mm |

|---|---|---|

| Annealed |  |

|

| Skin Passed |  |

|

| (Lightly)As-Rolled |  |

|

[Note] t…Thickness R…Internal Bend Radius

[Reference] Approximation of Bending Power

| V-Bending | P=0.6bt2σB/L |

|---|---|

| U-bending | P=0.6bt2σB (1+t / L ) |

[Note] t…Thckness b…Width L…Die Groove Width σB…Tensile Strength of Material

Apart from light drawing, an annealed or skin-passed finish is usually used because uniformity of drawing in all directions is required.

Cold-rolled special steel strip does not have the significant stretcher strain phenomenon of soft steel, but its drawing limit is lower.For deep drawing, intermediate annealing is applied and re-drawing is performed.

In the case of normal flat drawaing : Drawing Ratio=0.4

In the case of redrawing : Drawing Ratio=0.6

Drawing Ratio= d / D

d…Diameter of Product to be Drawn D…Diameter before Drawing

Reference|Approximate Formula(Round Drawing)

P = π dt σB m

[Note] t…Thickness m…Correction Factor (normally 0.4~1.0) σB…Tensile Strength of Material

Almost all cold-rolled special steels are heat-treated by quenching and tempering according to their applications.

The following points should be noted during this heat treatment process.

(1) Heat treatment and cooling should be performed uniformly under appropriate conditions.

(2) Avoid decarburization, scale formation, high-temperature corrosion, etc as much as possible.

(3) Use a quenching method that minimizes quenching distortion.

Generally, when performing heat treatment, the furnace temperature of the heat treatment furnace is measured and used as the material heating temperature.

However large discrepancies or irregularities may occur between the true material temperature and the measured furnace temperature,

it is necessary to examine the temperature characteristics and make appropriate temperature compensation carefully or change the heat treatment method.

The higher the carbon content of a cold-rolled special steel strip, the more likely it is to be decarburized, and the risk increases when heating at high temperatures.

High-temperature corrosion will occur if the material is heated with dirt or foreign objects adhering to it.

Therefore, pretreatment to clean the material surface and adjustment of the furnace atmosphere is necessary before heat treatment.

The standard furnace atmosphere is RX gas for quenching and NX gas for annealing, but other than these, N2 gas, H2 gas, AX gas, etc. are also used,

Neutral salt bath furnaces, metal bath furnaces, furnace tubes, and cases are also used to prevent direct exposure to the outside air.

The material is typically heated to the approximate midpoint of the specified quenching temperature range, and then held for several seconds to several minutes, depending on the material, dimensions, shape, required properties, and quenching method.Quenching conditions have a significant impact on product performance. If the quenching temperature is too high or the holding time is too long, it can lead to grain coarsening and a reduction in toughness, as well as an increased risk of decarburization. Conversely, if the temperature is too low or the holding time too short, the material may not harden completely, or soft spots may appear. Therefore, selecting the appropriate conditions is crucial.

For cooling, oil or water is generally used. Water cooling results in harder quenching than oil cooling, but it carries a higher risk of quenching distortion and cracking. Therefore, in the case of cold-rolled special steels, oil cooling is typically used, with some exceptions.

To prevent quenching distortion, martempering is performed by raising the oil temperature. In special cases, quenching is done in salt baths or metal baths (austempering). For ribbon-shaped materials or those with simple shapes, methods such as flat quenching or press quenching are also used.

| Grade | Quenching Temperature(℃) |

|---|---|

|

TE2 |

790~850 Oil cooling (760~820 Water Cooling) |

|

SK95(SK4) |

790~850 Oil cooling (760~820 Water Cooling) |

|

SK85(SK5) |

790~850 Oil cooling (760~820 Water Cooling) |

|

SK75(SK6) |

790~850 Oil cooling (760~820 Water Cooling) |

|

SK64(SK7) |

790~850 Oil cooling (760~820 Water Cooling) |

|

SKS51 |

790~850 Oil cooling (760~820 Water Cooling) |

|

SKS2 |

830~880 Oil cooling |

|

SKS7 |

830~880 Oil cooling |

|

S70C |

790~850 Oil cooling |

|

S60C |

800~860 Water Cooling |

|

S55C |

800~860 Water Cooling |

|

S45C |

800~860 Water Cooling |

|

S15C |

800~860 Water Cooling |

Materials that have undergone quenching become harder but lose ductility, becoming brittle. Therefore, tempering is essential to achieve a material with both toughness and strength.

Tempering conditions are determined according to the performance requirements of each product by referring to tests and the quenching and tempering performance curves of the steel grade.

Since the cold rolled special steel strip is small and tempering is often performed continuously, tempering may be performed for a long time when particularly high tenacity is required, but in general, tempering is performed for a short time, within a few minutes.

In cases where a short time is required for continuous operation, the tempering temperature may be raised slightly or the tempering may be performed repeatedly.

However, as a general rule, tempering at a lower temperature for a longer time will result in greater toughness than tempering at a higher temperature for a shorter time,

Therefore, it is necessary to avoid using tempering temperatures that are too high or time that is too short.

Tempering in an oil bath, metal bath, or salt bath can also reduce the time required for tempering compared to tempering in air.