nanoSUS™ is a stainless steel that has ultrafine grained (UFG) microstructures with average grain sizes smaller than 1 μm.

Compared to normal material, various property improvements can be expected, such as improved strength, fatigue properties, and workability by controlling the microstructure.

Thickness : 0.010mm-0.60mm *Contact Sales if your need 0.20mm-0.60mm.

Width : 3.0mm-300mm

Length : COIL or SHEET less than L2000mm

The following advantages can be expected with grain refinement.

Due to ultrafine grained (UFG) microstructures, roughness on the surface of bending parts are improved during metallic materials processing.

Normal materials with large crystal grains may not have a smooth shear surface due to grain dropout when fine pressing is performed.

Ultrafine grain steels can stabilize the contour shape of the fine-pressed shear surface.

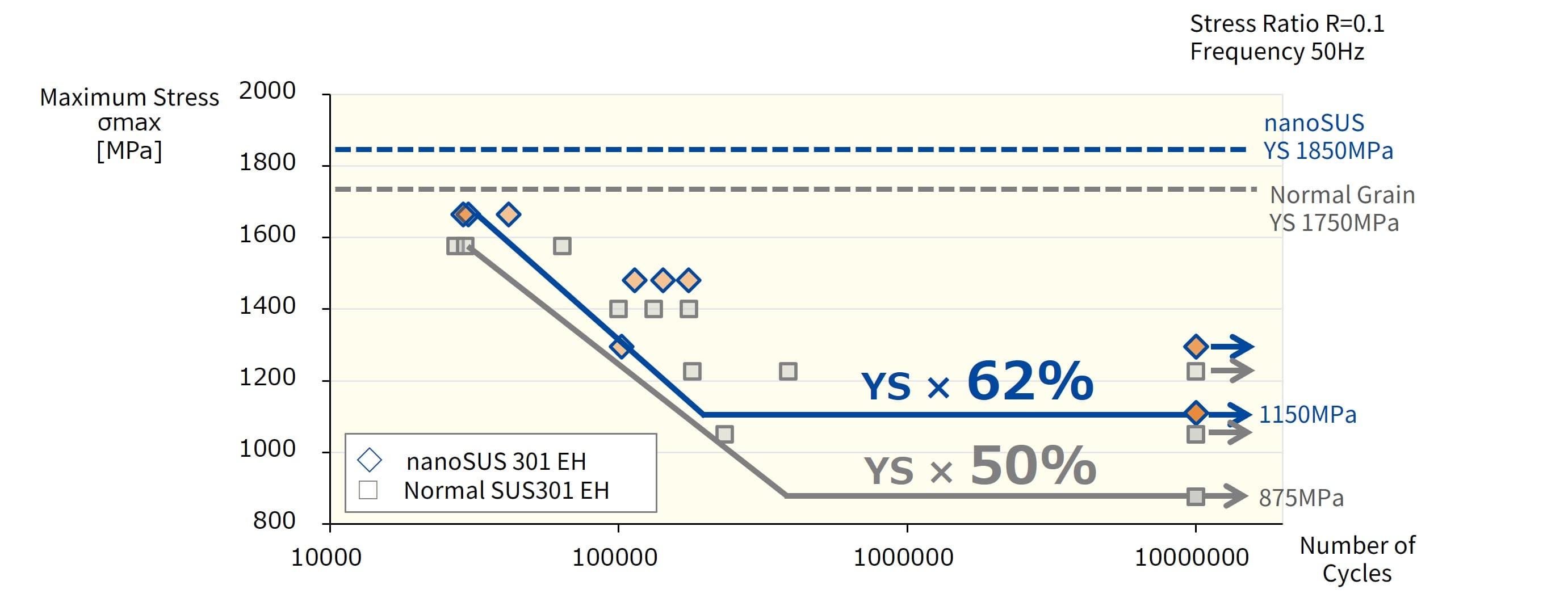

Improved fatigue properties enable longer service life of parts. The fatigue limit of SUS301 normal grain is about 50% of the proof stress (YS) while nanoSUS™ has a fatigue limit of 62% of YS, which is about 10% higher than that of normal grain.

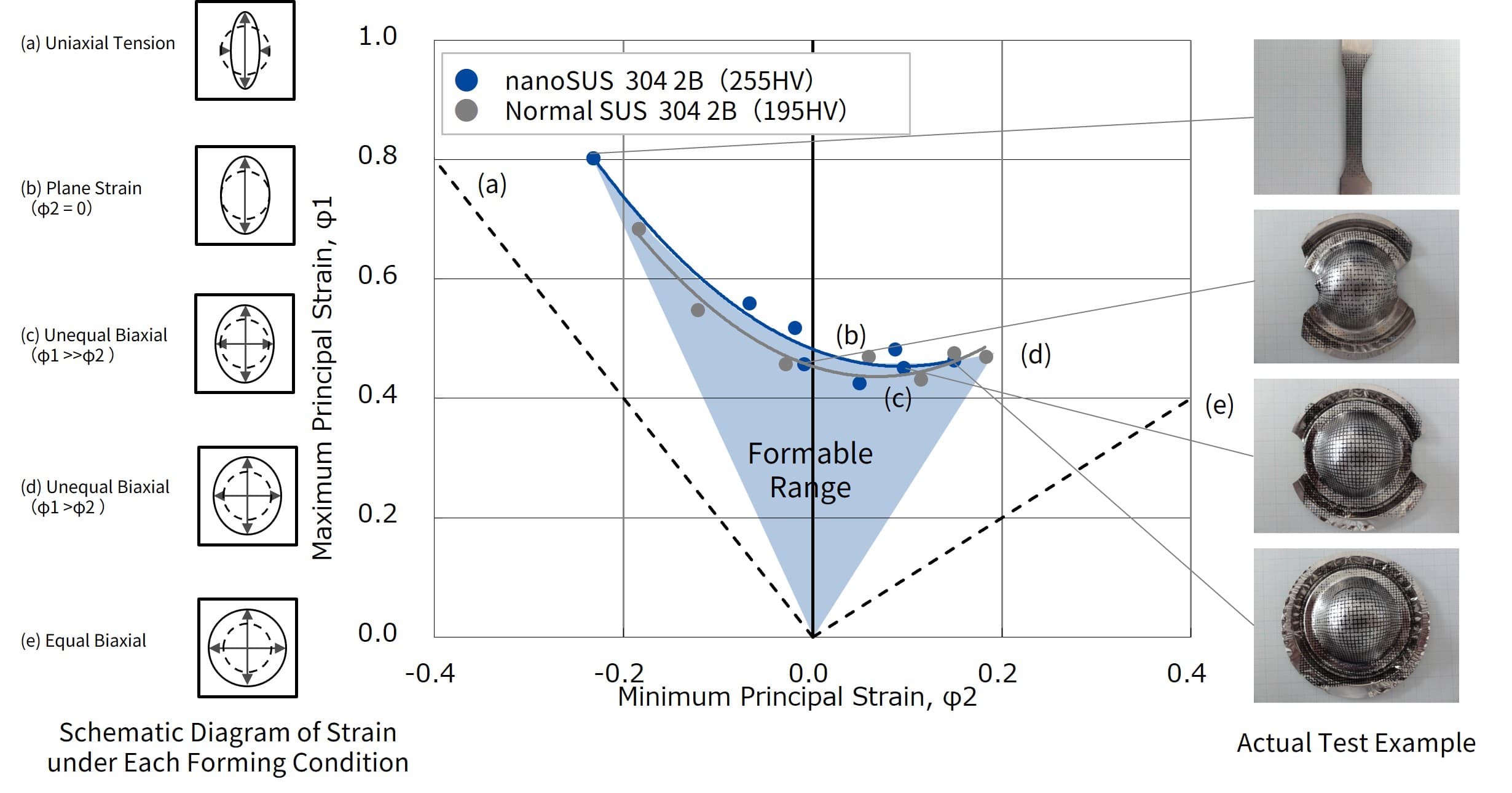

Compared to ordinary 2B material, nanoSUS™ 2B has higher hardness and higher resistance (YS), but has almost the same performance in terms of stretch formability.

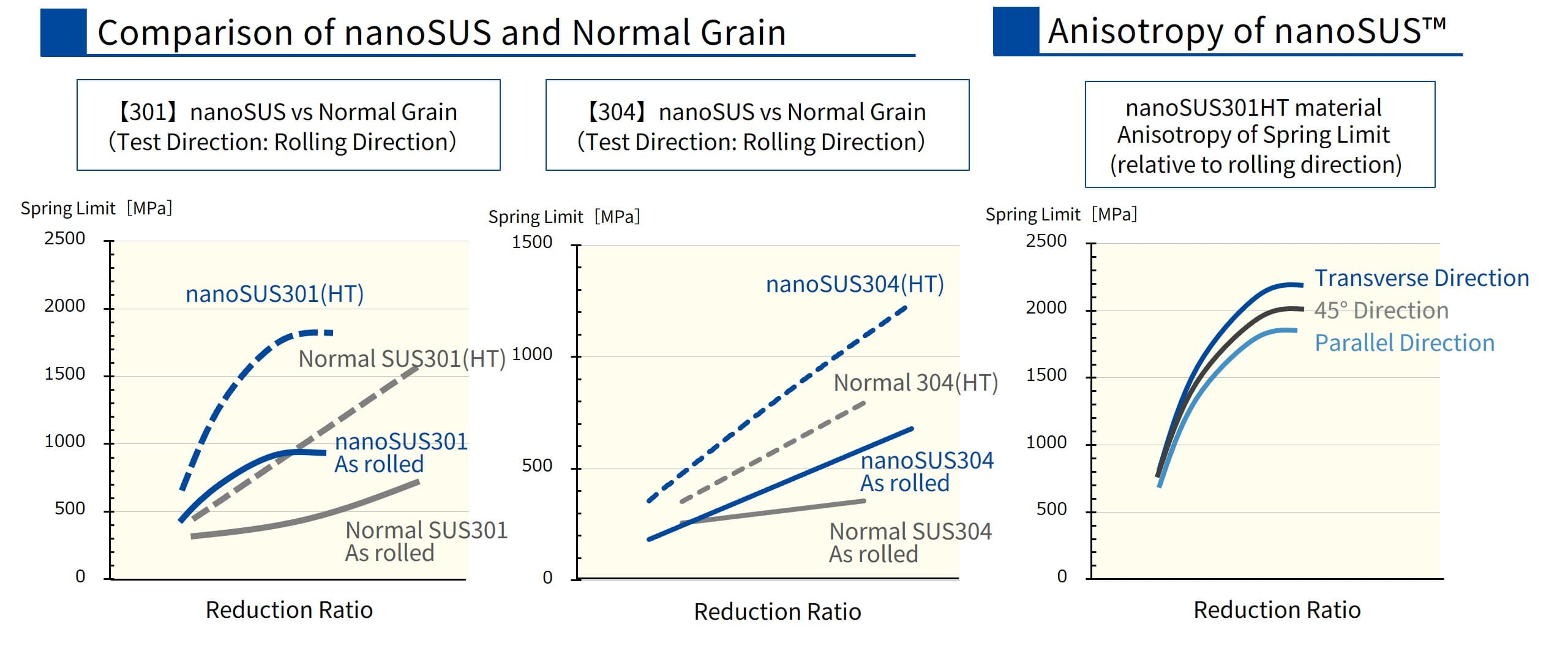

High spring limit values can be obtained by low temperature annealing (HT:Heat Treatment). In particular, nanoSUS™ 301 can achieve extremely high spring properties exceeding 1600 MPa in the rolling direction and 2000 MPa in the transverse direction, making it suitable for high-strength spring material applications.

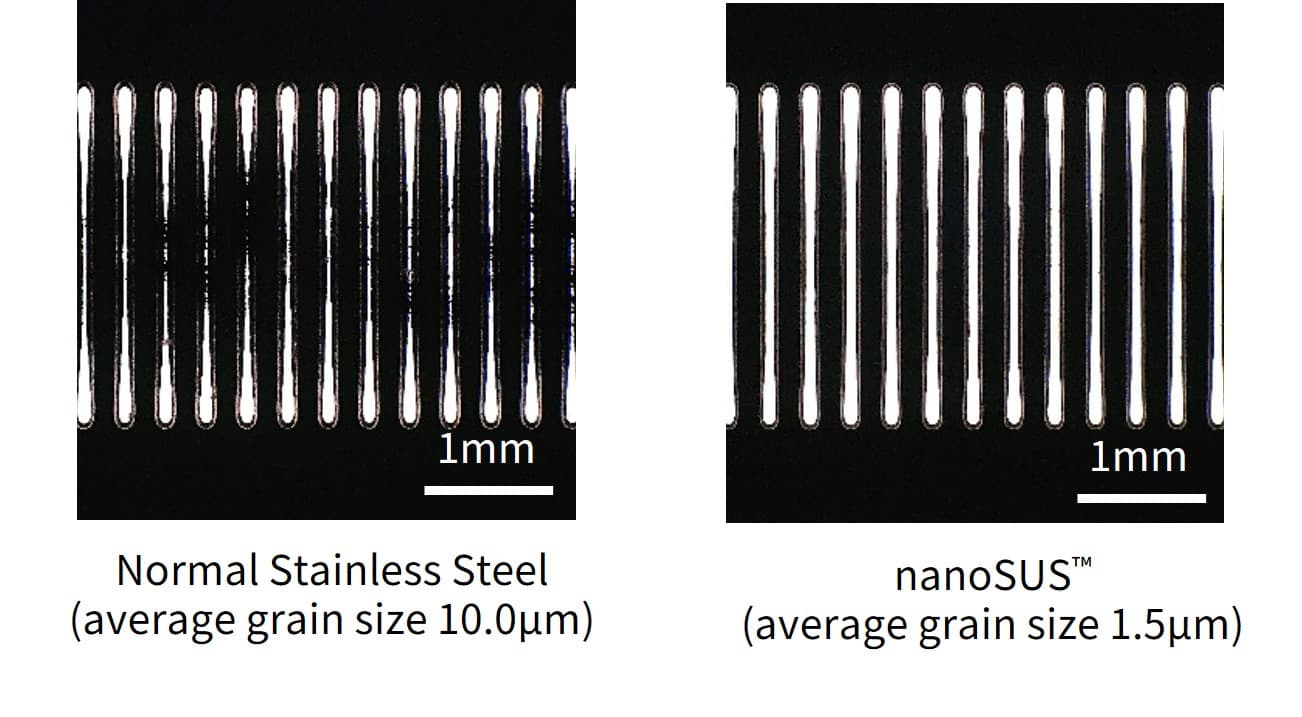

Fine grain structure minimizes skin roughness and dripping during etching, also enables finer and more precise etching process.

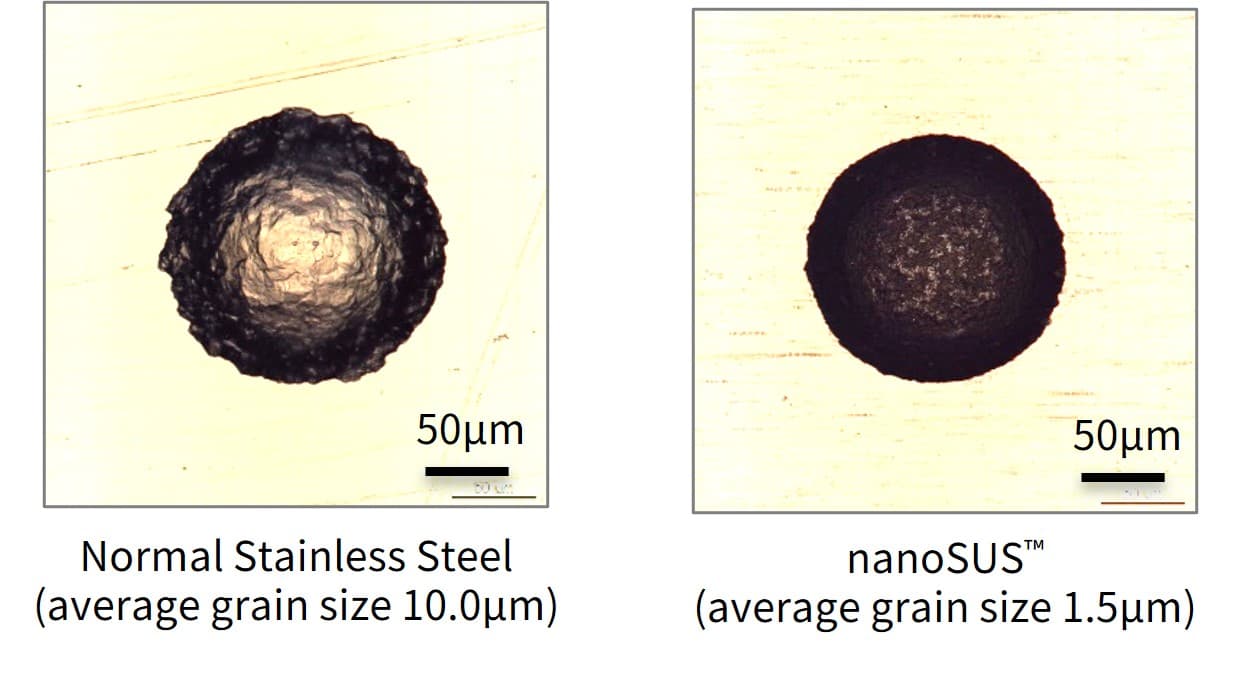

When making etched holes with a hole diameter of 0.22 mm, stainless steel normally does not penetrate, but nanoSUS does.

Normally, stainless steel is insufficiently etched in the center of the slit, but nanoSUS provides a good etched shape over the entire area.

It can be seen that nanoSUS has less skin roughness after half etching and that the edges of the round holes are machined with high precision.

TOKKIN's nanoSUS ultrafine grained material has the following advantages.

We can make it to foils (less than 0.10 mm thick) in all the stainless steels we manufacture.

nanoSUS 301 uses SUS301 raw material.

nanoSUS 304 uses SUS304 raw material.