A resistive material is a material whose composition is adjusted so that it is difficult to conduct electricity (high electrical resistance) in metals.

They are mainly classified into two types: "materials for electric resistance" used for resistors, etc. and "materials for electric heating" used for heating elements, etc.

"Materials for electric resistance" limit the flow of current through metal resistance, and "materials for electric heating" are used to generate heat due to metal resistance when an electric current is applied.

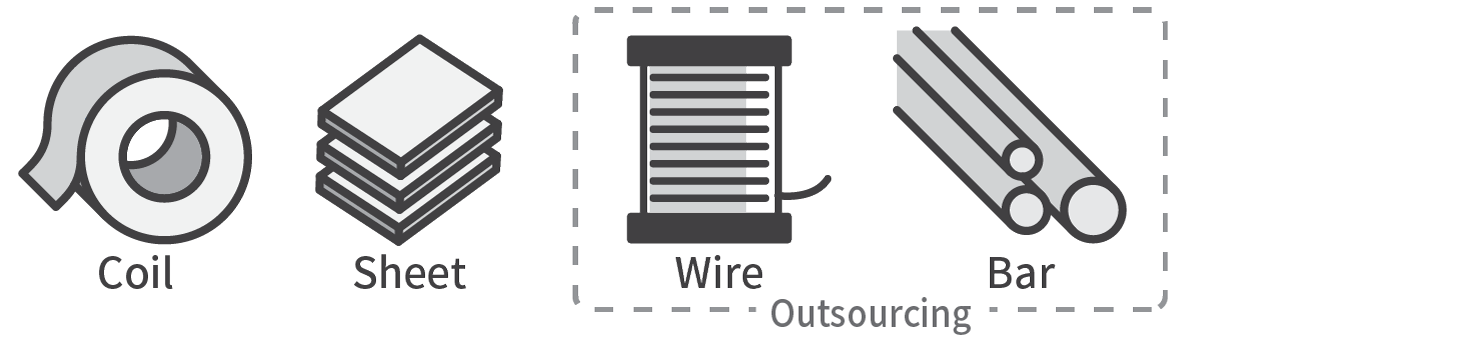

We manufacture various types of resistor materials in small lots with high quality.

Various Resistors, Heaters, Heating Elements, etc.

It depends on material grade, so please confirm details on each material grade page.

Please scroll horizontally to view.

*1 Evanohm® is a registered trademark of Carpenter Technology Corporation.

*2 MANGANIN® and ZERANIN® are registered trademarks of Isabellenhütte Heusler GmbH & Co. KG.

Each standard is for reference only.

Please scroll horizontally to view.

| Types | Product Name |

Other Alloy Designations | Standards | ||

|---|---|---|---|---|---|

| Germany DIN | China GB | Japan JIS | |||

| Ni-Cr | NCH-1 | ISA-CHROM 80 | NiCr8020 | 2080 Cr20Ni80 |

NCHRW1 GNC108R |

| NCH-2 | ISA-CHROM 60 | NiCr6015 | 1560 Cr15Ni60 |

NCHRW2 GNC112R |

|

| Ni-Cr-Al | Evanohm R ® *1 | ISAOHM | NiCr20AlSi | --- | --- |

| Cu-Ni | CN30 | ISAZIN | CuNi23Mn | B25 | GCN30R |

| CN49 | ISOTAN | CuNi44 | 6J40 | GCN49R | |

| Cu-Mn-Ni | MANGANIN® *2 | MANGANIN | CuMn12Ni | 6J12 6J13 |

GCM44 |

| Cu-Mn-Sn | ZERANIN® *2 30 | ZERANIN 30 | CuMn7Sn | 6J8 | --- |

| Fe-Cr-Al | TJR-1 | Resistohm | CrAl205 | 0Cr20Al5 | GFC142 |

*1 Evanohm® is a registered trademark of Carpenter Technology Corporation.

*2 MANGANIN® and ZERANIN® are registered trademarks of Isabellenhütte Heusler GmbH & Co. KG.

Please scroll horizontally to view.

[mass%]

| Product Name |

JIS | C | Si | Mn | Cu | Al | Cr | Ni | Sn | Fe | Others | Density |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NCH-1 | GNC108 | 0.15 max |

0.75-1.6 | 2.5 max |

ー | ー | 19-21 | 77 min | ー | 1.0 max |

ー | 8.4 |

| NCH-2 | GNC112 | 0.15 max |

0.75-1.6 | 1.5 max |

ー | ー | 15-18 | 57 min | ー | Bal. | ー | 8.3 |

| EVANOHM®*1 R | - | ー | 1 | 1 | 2 | 2.5 | 20 | 73.5 | ー | ー | ー | 8.1 |

| CN30 | GCN30 | ー | ー | 1.5 max |

ー | ー | ー | 20-25 | ー | ー | Cu+Ni+Mn 99 min | 8.9 |

| CN49 | GCN49 | ー | ー | 0.5-2.5 | ー | ー | ー | 42-48 | ー | ー | Cu+Ni+Mn 99 min |

8.9 |

| MANGANIN®*1 | GCM44 | ー | ー | 10-13 | ー | ー | ー | 1-4 | ー | ー | Cu+Ni+Mn 98 min | 8.4 |

| ZERANIN®*1 30 | - | ー | ー | 7 | Bal. | ー | ー | ー | 2.3 | ー | ー | 8.5 |

| TJR-1 (Stainless Steels) |

- | 0.015 max | 1.0 max |

1.0 max |

ー | 4.5-6 | 19-21 | ー | ー | Bal. | ー | 7.3 |

*1 Evanohm® is a registered trademark of Carpenter Technology Corporation.

*2 MANGANIN® and ZERANIN® are registered trademarks of Isabellenhütte Heusler GmbH & Co. KG.

We can adjust conductor resistance upon your request.

Even with the same material, conductor resistance varies depending on the product dimensions (thickness / width) and the degree of softening (tempering) of the product. By controlling these factors, we can achieve high-precision conductor resistance values.

■Difference between volume resistivityand conductor resistance.

【Relationship between Volume Resisivity (ρ) and Conductor Resistance(R)】

ρ : Volume Resistivity(μΩ・m)

t :Thickness(mm)

w :Width(mm)

Please scroll horizontally to view.

| Product Name |

Types | Typical Value | Features | |||

|---|---|---|---|---|---|---|

| Volume Resistivity [μΩ・m] |

Maximum Operating Temperature [℃] |

Hardness [HV] |

Magnetism | |||

| Electrical resistance nickel-chromium alloys for heating |

1.08 | 1100 | 250 max | Non-magnetic |

|

|

| 1.12 | 1000 | 250 max | Non-magnetic | |||

| Iron-chromium alloys for electrical heating |

1.42 | 1200 | 250 max | Magnetic |

|

|

| 1.23 | 1100 | 250 max | Magnetic | |||

| Electrical resistance copper-nickel alloys for general use |

0.05 | 300 | 120 max | Non-magnetic |

|

|

| 0.10 | 300 | 120 max | Non-magnetic | |||

| 0.15 | 400 | 120 max | Non-magnetic | |||

|

(Stainless Steels) |

- | 1.42 | 1200 | 250 max | Magnetic |

|

Each standard is for reference only.

Please scroll horizontally to view.

| Types | Product Name |

Other Alloy Designations | Standards | ||

|---|---|---|---|---|---|

| Germany DIN | China GB | Japan JIS | |||

| Ni-Cr | NCH-1 | ISA-CHROM 80 | NiCr8020 | 2080 Cr20Ni80 |

NCHRW1 |

| NCH-2 | ISA-CHROM 60 | NiCr6015 | 1560 Cr15Ni60 |

NCHRW2 | |

| Cu-Ni | CN5 | ALLOY 30 | CuNi2 | --- | GCN5R |

| CN10 | ALLOY 60 | CuNi6 | B5 | GCN10R | |

| CN15 | ALLOY 90 | CuNi10 | BFe10-1-1 | GCN15R | |

| Fe-Cr-Al | FCH-1 | Resistohm | CrAl255 | 0Cr25Al5 | FCHWR1 |

| FCH-2 | --- | --- | --- | FCHRW2 | |

| TJH-1 | Resistohm | CrAl205 | 0Cr20Al5 | FCHRW1 | |

Please scroll horizontally to view.

[mass%]

| Product Name |

JIS | C | Si | Mn | P | S | Al | Cr | Ni | Fe | Others | Density |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NCH-1 | NCHRW1 | 0.15 max | 0.75-1.6 | 2.5 max |

ー | ー | ー | 19-21 | 77 min | 1.0 max |

ー | 8.4 |

| NCH-2 | NCHRW2 | 0.15 max | 0.75-1.6 | 1.5 max |

ー | ー | ー | 15-18 | 57 min | Bal. | ー | 8.3 |

| FCH-1 | FCHRW1 | 0.1 max | 1.5 max | 1.0 max |

ー | ー | 4-6 | 23-26 | ー | Bal. | ー | 7.2 |

| FCH-2 | FCHRW2 | 0.1 max | 1.5 max |

1.0 max |

ー | ー | 2-4 | 17-21 | ー | Bal. | ー | 7.4 |

| CN5 | GCN5 | ー | ー | 1.0 max |

ー | ー | ー | ー | 0.5-3 | ー | Cu+Ni+Mn 99 min | 8.9 |

| CN10 | GCN10 | ー | ー | 1.0 max |

ー | ー | ー | ー | 4-7 | ー | Cu+Ni+Mn 99 min | 8.9 |

| CN15 | GCN15 | ー | ー | 1.0 max |

ー | ー | ー | ー | 8-12 | ー | Cu+Ni+Mn 98 min | 8.9 |

| TJH-1(Stainless Steels) | - | 0.015 max | 1.0 max |

1.0 max |

0.04 max |

0.03 max |

4.5-6 | 19-21 | ー | Bal. | ー | 7.3 |

Heat Quantity depends on the product dimensions (thickness / width), volume resistivity(ρ), and coefficient of increase in resistance.

Please let us know your requirements so that we can propose the grade and dimensions that best suit your needs.

【Relationship between heat quantity (Q), volume resistivity (ρ), and coefficient of increase in resistance】

R :Electric Resistance(Ω)

ρ :Volume Resistivity(μΩ・m)

k :Coefficient of Increase in Resistance

I :Electric Current(A)

T :Time(sec.)

t :Thickness(mm)

w :Width(mm)

We can make it to foils (less than 0.10 mm thick) in all the materials we manufacture.

We define ultra-thin metal foil less than 10 microns thick as “GOKUHAKU”. We are capable of manufacturing foils as thin as 2 Microns.