Cold Rolled Steel Strips

Soft Magnetic Iron Steels (pure iron)

SUY-1 | Soft Magnetic Iron

Overview & Features

This grade is specified in "JIS C2504 Soft magnetic Irons", and is generally called "Pure iron". SUY is classified into four types, from Type 0 (SUY-0) to Type 3 (SUY-3), depending on the value of magnetic properties. Because of low carbon and Impurities, good drawability and soft magnetic properties※, it is mainly used for motor applications. and recently, magnetic shielding application are also increasing. ※Magnetic properties include magnetic flux density and coercive force, which can be maximized by magnetic annealing again after cold working.

What is the difference between SUYP and SUYB?

In some cases, SUY is followed by P or B to indicate SUYP-1 or SUYB-1.This means P: Plate (plate/strip/strip) and B: Bar (bar/wire), and is an expression of shape within the name of the steel grade.

Example: SUYP-1 = SUY-1 with the shape of P (Plate, Strip, Stripe)

Examples of Applications

For deep drawing, Coining, etc., Electromagnetic, etc., Motor Yokes, Magnetic Shielding Plates

Available Shapes

Manufacturable Range (COIL, SHEET)

Thickness

0.030-2.5mm

Width

3.0-300mm

Length

COIL or SHEET less than 2000mm

This is the manufacturing range of coils and sheets we manufacture.

Standards

Unless otherwise specified, we manufacture in accordance with JIS standards.

JIS

SUY-1 (C2504)

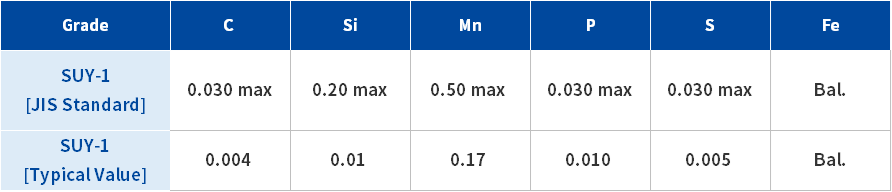

Chemical Composition

JIS standards and reference value of TOKKIN's chemical composition are shown in the table below.

Physical Properties

The following values are typical values for low carbon steel(Fe-0.06C).

Density

7.87 g/cm³

Specific Heat

481 J/(kg・K)

Electrical Resistivity

13 μΩ・cm

Young's Modulus

206 GPa

Thermal Expansion

11.7×10-6/K (0~100℃)

Thermal Conductivity

73.3 W/(m・K)

Magnetism

Soft Magnetism *Please refer to the section below for details.

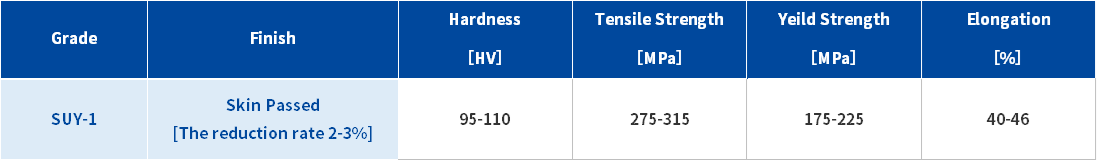

Mechanical Properties

The mechanical properties of SUY-1 are as follows.

Generally it is supplied as skin-passed, but it can be manufactured in hardness upon your request.

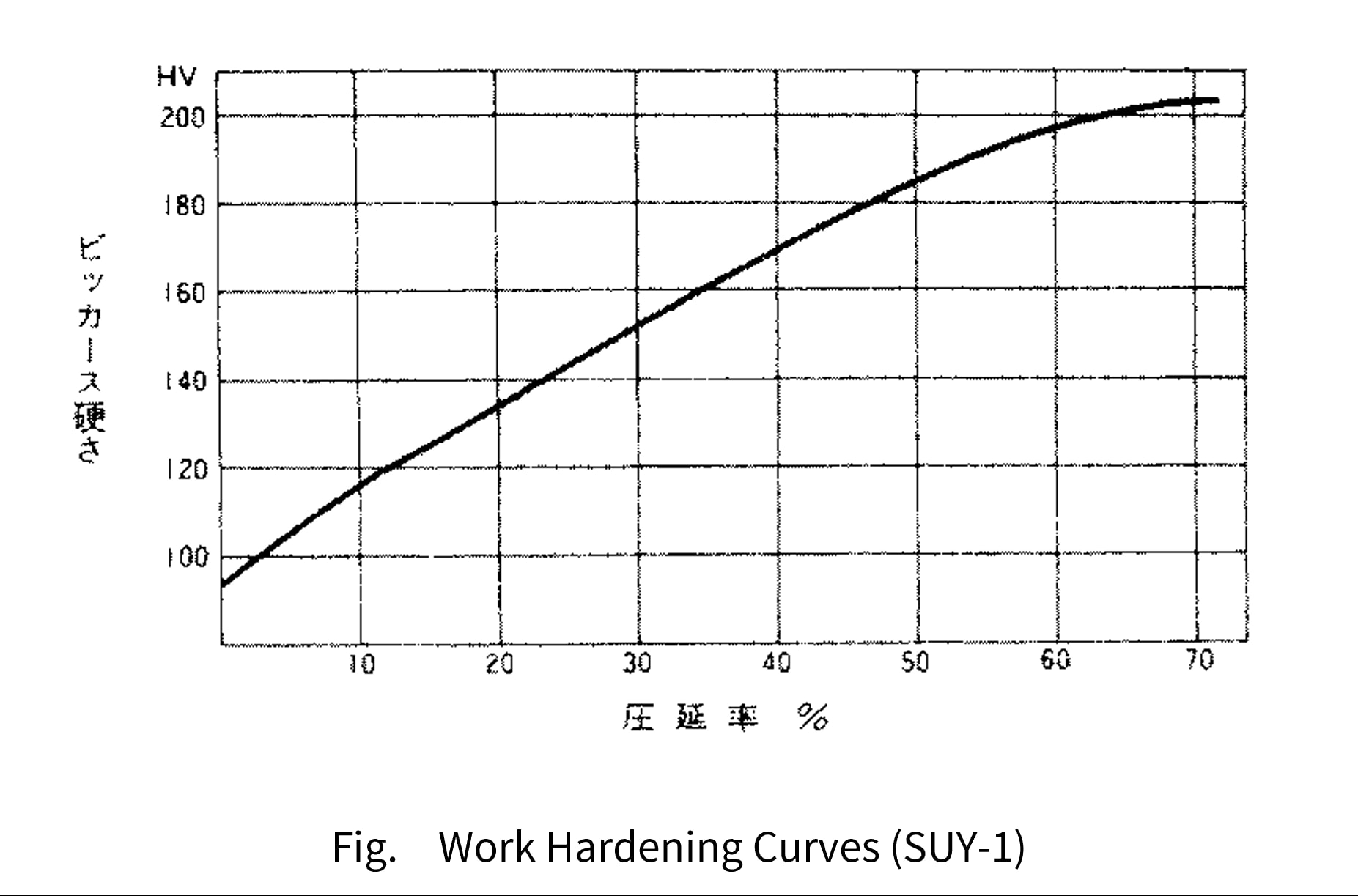

The table below shows "Typical mechanical properties of skin passed materials (rolling ratio 2-3%)

and the graph shows "Change in hardness when annealed material is cold rolled.

Magnetic Properties

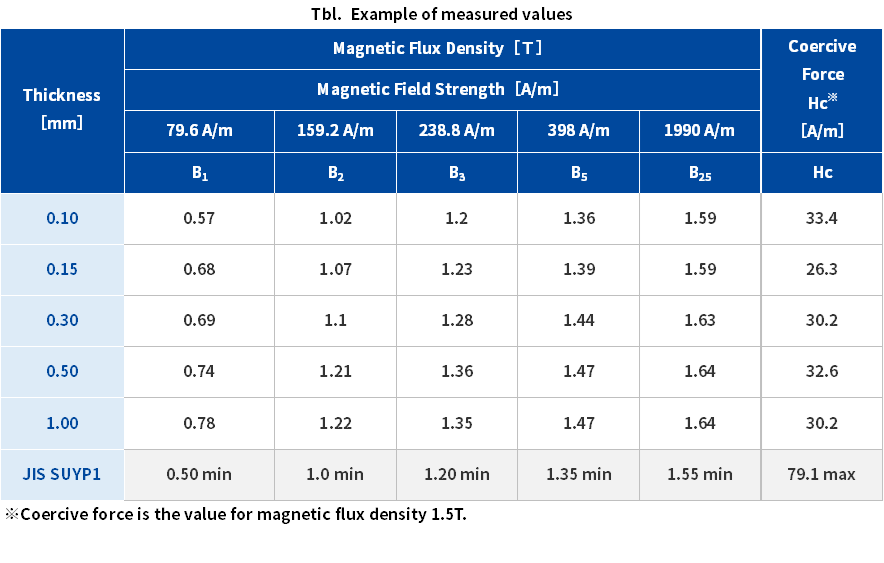

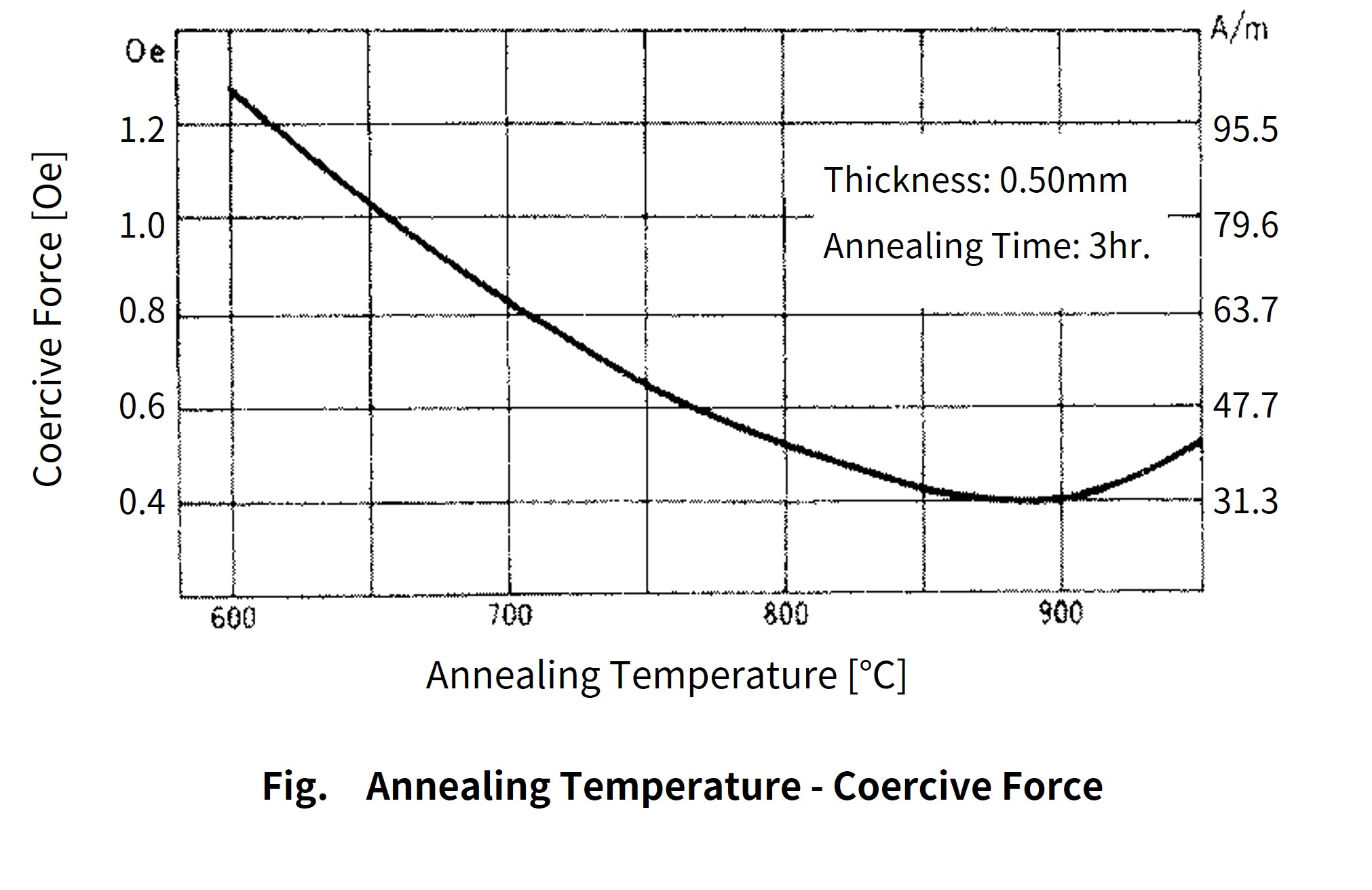

Materials with thickness of over 0.10mm and magnetic annealing is performed under the condition of [hold at 850℃ for3hours , then slow cooling]meet the standards of JIS SUY-1 as shown in the table below.

Also,the correlation of aneealing temperature and coercive force is shown in the figure below and it has same properties as JIS SUY-1.

Related Pages

Soft Magnetic Materials

Soft magnetic material is easily magnetized when a magnetic field is applied, but returns to its original state when the magnetic field is removed. We also manufacture our original steel grades such as electromagnetic stainless steel with corrosion resistance and extremely high strength.