Soft magnetic materials are materials that become magnetized when exposed to an external magnetic field, but return to their original (non-magnetized) state once the field is removed. They are characterized by high magnetic permeability (μ) and low coercivity (Hc). Because of its excellent magnetizing, demagnetizing, and magnetic shielding properties, soft magnetic materials are widely used in motor cores, shielding cases, digitizers, and other electronic devices. As the number of components in a single device increases, susceptibility to high-frequency noise and magnetic interference also rises. Consequently, the demand for materials with superior magnetic characteristics is steadily growing.

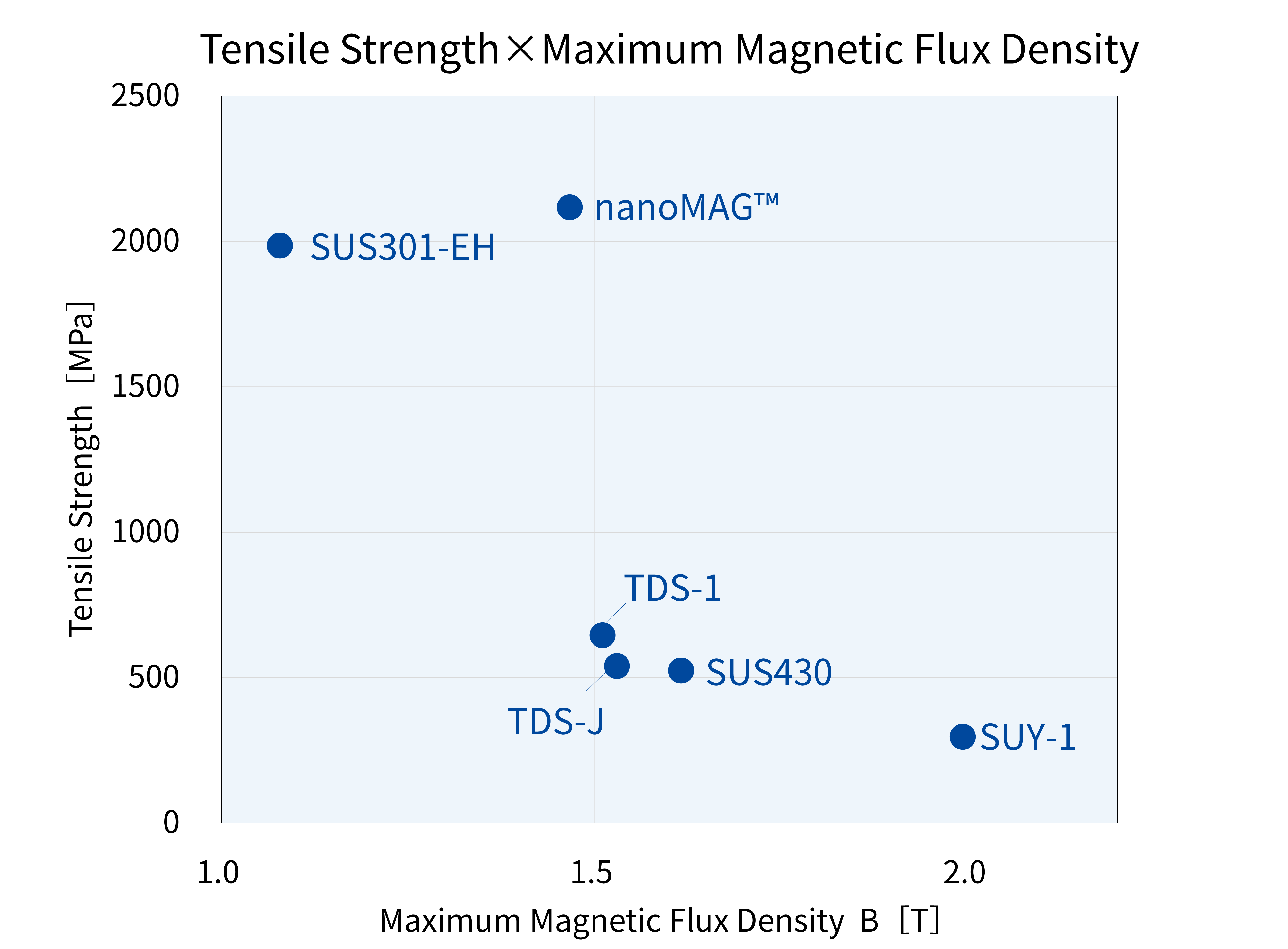

Furthermore, in response to growing demands for miniaturization, enhanced strength, and improved corrosion resistance, we are developing proprietary materials that integrate these features with excellent soft magnetic characteristics.

Yokes, Motor Cores, Rotor Cores, Digitizers, HDD Covers, Shielding Cases, Connectors

For available dimensions, please refer to the detailed page for each steel grade.

Please scroll horizontally to view.

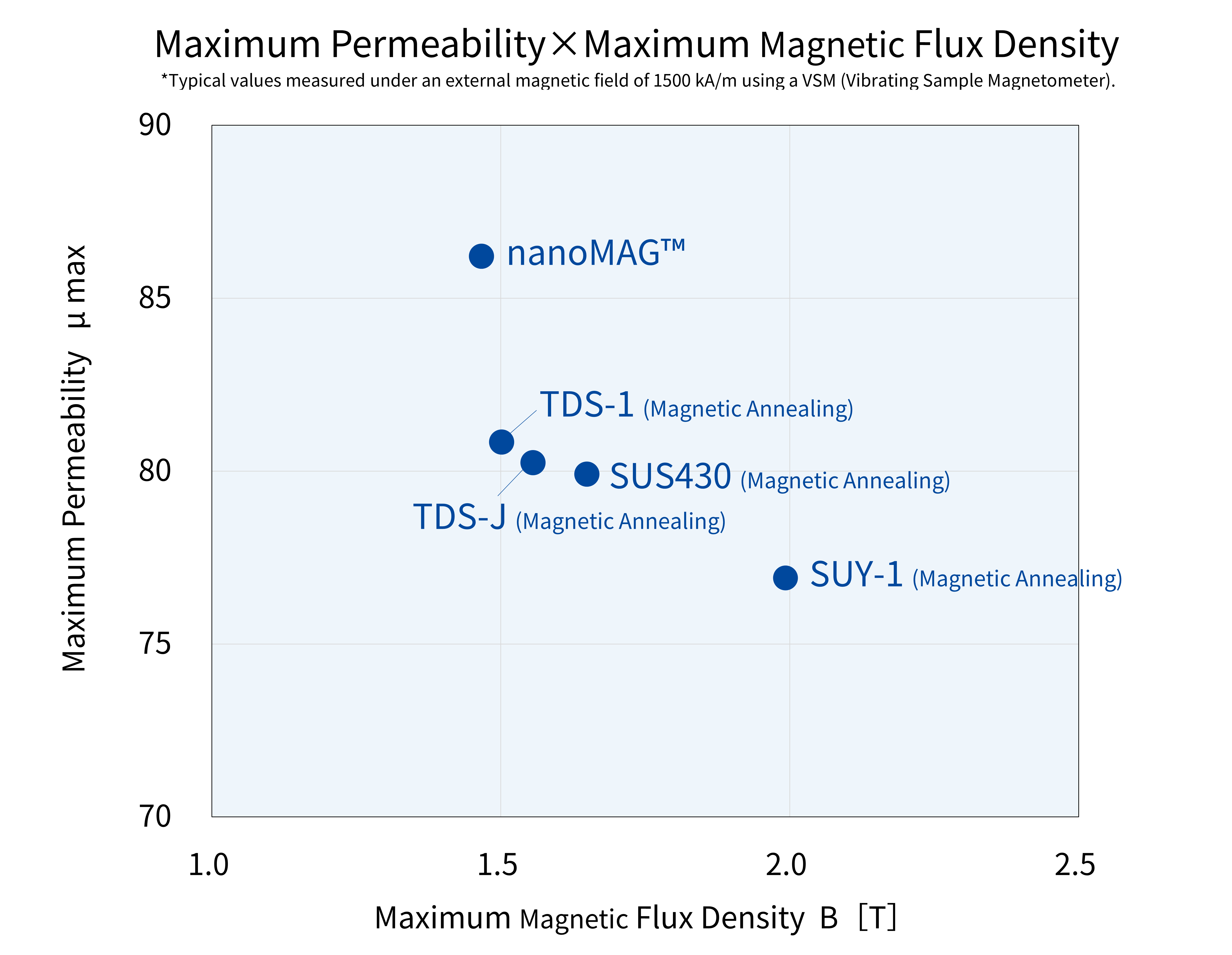

| Type | Grade | Condition | Maximum Permability μmax |

Saturation Magnetic Flux Density B [T] |

Coercive Force Hc [A/m] |

Volume Resistivity ρ [μΩ・cm] |

Corrosion Resistance *2 |

High Strength *2 |

Main Application |

|---|---|---|---|---|---|---|---|---|---|

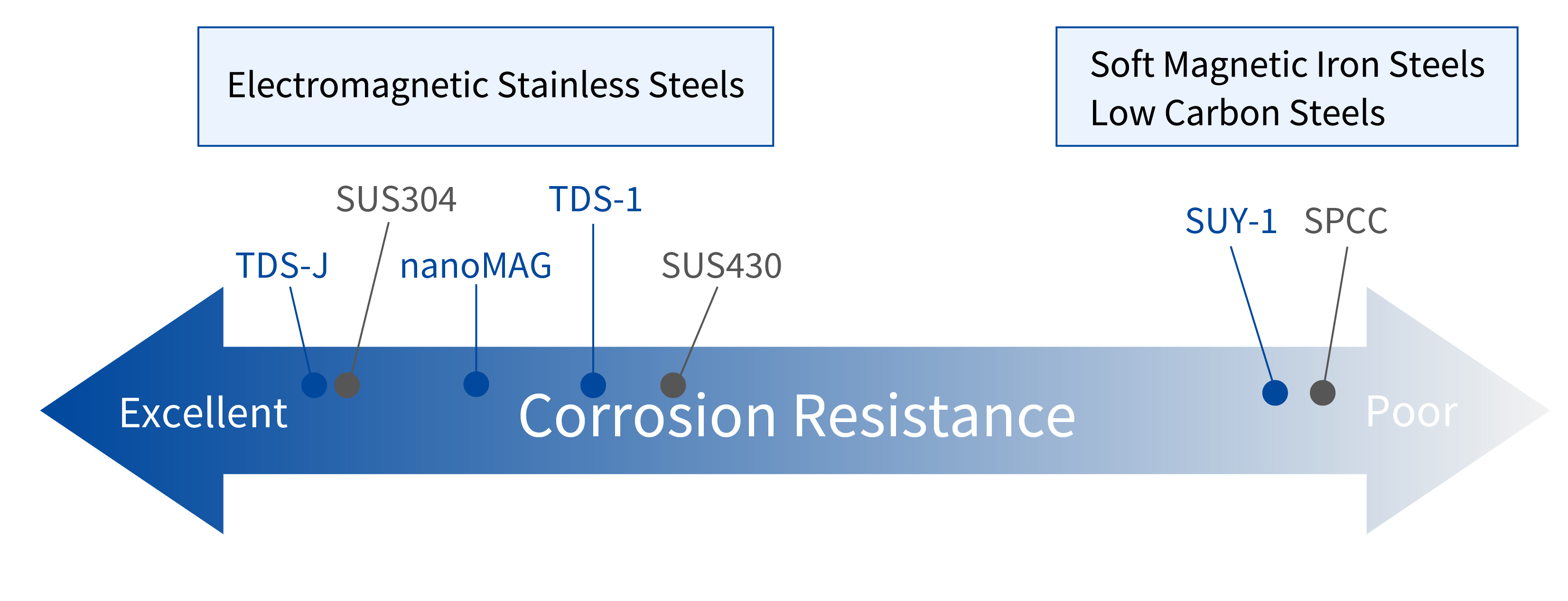

| Soft Magnetic Iron steels | SUY-1 | After Magnetic Annealing | 77 | 2.03 | 779 | 13 | R | R |

Yokes, |

| Low Carbon Steels | SPCC | Standard Tempering (SB) |

80 | ー | ー | 13 | R | R | Camera Modules |

| Electromagnetic Stainless Steels | TDS-1 | After Magnetic Annealing | 80 | 1.56 | 753 | 81 | A | A | Shielding Cases, Digitizers |

| TDS-J | After Magnetic Annealing | 80 | 1.56 | 344 | 51 | S | A | Shielding Cases, Digitizers | |

| nano MAG |

After Heat Treatment *1 |

86 | 1.46 | 1045 | 73 | A | S | Motor Cores, Rotor Cores |

*1 nanoMAG can be used without magnetic annealing, requiring only manufacturing processes like pressing.

*2 S ・・・ Excellent A ・・・ Good B ・・・Moderate R ・・・ Restricted

Please scroll horizontally to view.

[mass%]

| Type | Grade | C | Si | Mn | P | S | Cr | Ni | Fe | Others |

|---|---|---|---|---|---|---|---|---|---|---|

| Soft Magnetic Iron steels |

SUY-1 | 0.030 max | 0.20 max | 0.50 max | 0.030 max | 0.030 max | - | - | Bal. | - |

| Low Carbon Steels |

SPCC | 0.15 max | - | 0.60 max | 0.100 max | 0.035 max | - | - | Bal. | - |

| Electromagnetic Stainless Steels |

TDS-1 | 0.08 max | 1.50-2.50 | 1.00 max | 0.040 max | 0.010 max | 16.00-18.00 | 1.50 max | Bal. | - |

| TDS-J | 0.025 max | 1.00 max | 1.00 max | 0.040 max | 0.030 max | 20.00-23.00 | - | Bal. | Cu 0.30-0.80 Ti 0.80 max |

|

| nanoMAG | 0.09 max | 1.00 max | 1.00 max | 0.040 max | 0.030 max | 16.00-18.00 | 6.50-7.75 | Bal. | Al 0.75-1.5 |

Please scroll horizontally to view.

| Type | Grade | Density [g/cm3 ] |

Specific Heat [J/(kg・K)] |

Electrical Resistance [μΩ・cm] |

Young's Modulus [GPa] |

Coefficient of Thermal Expansion [×10-6/K] |

Thermal Conductivity [W/(m・K)] |

Melting Point [℃] |

|---|---|---|---|---|---|---|---|---|

| Soft Magnetic Iron Steels Low Carbon Steels |

SUY-1 SPCC * |

7.87 | 481 | 13 | 206 | 11.7 (0-100℃) |

73.3 | 1530 |

| Electromagnetic Stainless Steels |

TDS-1 | 7.73 | 420 | 70 | 206 | 11.3 (0-100℃) |

25.1 | 1460- 1500 |

| TDS-J | 7.74 | 440 | 58 | 204 | 10.5 (20-100℃) |

22.5 | 1460- 1500 |

|

| nanoMAG | 7.81 | 420 | 79 | 200 | 15.3 (0-100℃) |

16.3 | 1414- 1447 |

For mechanical properties, please refer to the detailed page for each steel grade.