Alloys based on Nickel (Ni), Chromium (Cr), Cobalt (Co), and Titanium (Ti) are superior to stainless steel in terms of heat resistance and corrosion resistance.

TOKKIN manufactures a variety of nickel-based alloys, cobalt-based alloys, titanium-based alloys, and others.

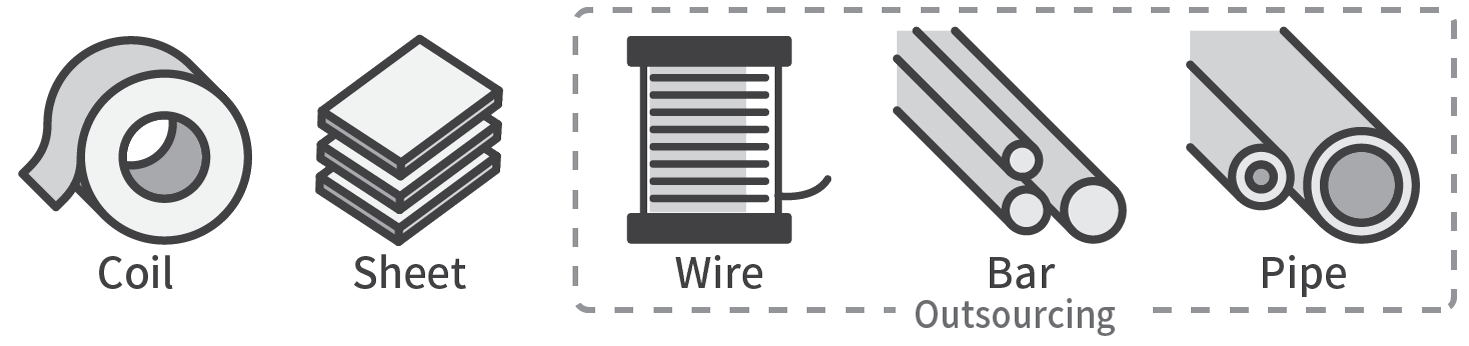

We not only supply cold-rolled thin sheets, strips, and foils manufactured by TOKKIN, but also supply sheets, wires, bars, and ultra-thin pipes purchased from our domestic and overseas partners upon your request.

It depends on the material and shape, please contact us first.

For HC-22, HC-276, Alloy 625, Alloy 718, Alloy X750, and MP35N, the details page shows the size range of coils and plates manufactured by us.

Please click on the alloy name to go to the detailed page of each alloy.

The table below lists only typical compositions. Please refer to the detail pages for other compositions.

Please scroll horizontally to view.

| Alloys Name | UNS No. | Typical Chemical Compositions [mass%] | Discription | |||

|---|---|---|---|---|---|---|

| Cr | Ni | Mo | Others* | |||

| HC-276 |

N10276 | 15.50 | 57.00 | 16.00 | HC-276 has resistance to wide range of corrosive environments and its welded portions also have good corrosion resistance. It is also used in applications requiring strength in high temperatures. We provide HASTELLOY C276 or its equivalent material. |

|

| HC-22 | N06022 | 22.00 | 56.00 | 13.00 | HC-22 has excellent overall corrosion resistance among Ni-Cr-Mo alloys. It has extremely excellent resistance to reducing and oxidizing corrosive environments, and is used in applications where reduction and oxidation are repeated. We provide HASTELLOY C22 or its equivalent material. |

|

| Alloy B-3 | N10675 | 1.50 | Bal. | 28.50 | Alloy B-3 has excellent corrosion resistance to hydrochloric acid, sulfuric acid, and other corrosive reducing environments. Also, it has excellent thermal stability, formability, and stress corrosion cracking resistance. | |

| Alloy C-2000 | N06200 | 23.00 | Bal. | 16.00 | Alloy C-2000 has excellent resistance to reducing and oxidizing corrosive environments. Compared to C-276, it shows superior corrosion resistance and stress corrosion cracking resistance under certain fixed conditions. | |

| Alloy C-4 | N06455 | 16.00 | 62.00 | 15.50 | Alloy C-4 has corrosion resistance equivalent to C-276 and excellent high-temperature stability between 650°C and 1040°C. | |

| Alloy X | N06002 | 22.00 | 47.00 | 9.00 | Fe 18.5 | Alloy X has an excellent balance of high-temperature strength, oxidation resistance, and formability at 1200°C. It is most commonly used in aerospace applications, industrial gas turbine engine combustion chambers, exhaust pipes, and similar applications. |

| Alloy 214 | N07214 | 16.00 | 75.00 | 0.50 | Alloy 214 has excellent oxidation resistance, carburization resistance, and chlorine resistance properties at temperatures up to 1260°C. It is uesd in components exposed to severe high-temperature environments, such as gas turbines, metal honeycombs, gas turbines, etc. |

|

| Alloy 230 | N06230 | 22.00 | 53.00 | 2.00 | W 14.0 | Alloy 230 is an alloy with excellent balance of workability, thermal cycle resistance, oxidation resistance, thermal stability and strength among major heat-resistant alloys. It is used in gas turbines, fossil fuel plants, chemical plants, and other plants requiring heat treatment. |

| Alloy 242 | N10242 | 9.00 | 60.00 | 25.00 | Alloy 242 is an age-hardening alloy with excellent strength in temperatures up to 705°C. Also, it has oxidation resistance in temperatures up to 815°C, low thermal expansion properties and high formability, as well as excellent resistance in high-temperature fluorine and fluoride resistant environments. It is used in gas turbines, chemical plants, fluoropolymer plastic production equipments, and CPI applications. |

|

| Alloy 263 | N07263 | 20.00 | Bal. | 6.00 | Co 20.0 | Alloy 263 is an age-hardening alloy with excellent formability in temperature range of 540°C to 870°C and excellent weldability. |

| Alloy 282 HAYNES® 282 |

N07208 | 19.50 | 57.00 | 8.50 | Co 10.0 | Alloy 282 is a super alloy with good weldability and workability, and excellent heat resistance properties unmatched by any other alloys. It is used in aerospace and automotive applications where high-temperature properties are required. We provide HAYNES 282 or its equivalent material. |

| Alloy 600 | N06600 | 15.50 | 72.00 | - | Alloy 600 is a Nickel-based alloy with excellent oxidation resistance under high temperature, It has high corrosion resistance to alkali. | |

| Alloy 601 | N06601 | 23.00 | 60.50 | - | Fe 14.0 | Alloy 601 has excellent workability, corrosion resistance, weldability, and strength without requiring heat treatment, and is used in temperatures ranging from cryogenic to 982°C. |

| Alloy 625 | N06625 | 21.50 | 58.00 | 9.00 | Alloy 625 is a solid solution strengthened alloy with excellent corrosion resistance and heat resistace, and good weldability. We provide Inconel 625 or its equivalent material. |

|

| Alloy 718 | N07718 | 19.00 | 52.50 | 3.05 | Fe 18.0 | Alloy 718 has workability under solution treatment condition, excellent strength and corrosion resistance after heat treatment, and weldability. It is used in temperatures ranging from cryogenic to 982°C. We provide Inconel 718 or its equivalent material. |

| Alloy X750 | N07750 | 15.50 | 70.00 | - | Alloy X750 is an age-hardening alloy with excellent strength in the temperature range up to 815℃. We provide Inconel X750 or its equivalent material. |

|

| Alloy 800 | N08800 | 21.00 | 32.00 | - | Fe 45.0 | Alloy 800 is an alloy with stable structure even when kept at high temperature for long periods, good strength and resistance to carburization. It also has good corrosion resistance in damp environments, and excellent workability. |

| Alloy 825 | N08825 | 21.50 | 42.00 | 3.00 | Alloy 825 has excellent corrosion resistance to both reducing and oxidizing acids, especially sulfuric and phosphoric acids, as well as resistance to stress corrosion cracking, pitting, and crevice corrosion. | |

| Alloy 925 | N09925 | 21.00 | 44.00 | 3.00 | Alloy 925 is a precipitation hardening alloy that shows good corrosion resistance equivalent to Inconel 825 in wide range of corrosive environments. | |

| Alloy 400 | N04400 | - | 66.50 | - | Cu 30.0 | Alloy 400 has strength and good workability, and also has good corrosion resistance in wide range of environments including seawater, acid, and alkalies. This is one of Nickel alloys that has been widely used for many years. |

| Alloy K500 | N05500 | - | 66.50 | - | Cu 30.0 | Alloy K500 is a precipitation hardening alloy with corrosion resistance equivalent to Monel 400, but with higher strength and hardness. It is completely non-magnetic even at extremely low temperatures of -100°C. |

| Alloy 902 | N09902 | 5.33 | 42.25 | - | Fe 45.0 | Alloy 902 is a precipitation hardening Ni-Fe-Cr alloy. Its elastic modulus can be kept constant between -45°C and 60°C depending on cold-rolling reduction rate and heat treatment conditions. |

| Alloy 90 | N07090 | 19.50 | 53.00 | - | Co 18.0 | Alloy 90 is a precipitation hardening alloy with excellent corrosion and oxidation resistance, and with high creep resistance at temperatures up to 920°C. |

| Alloy 41 |

N07041 | 19.00 | 52.00 | 10.00 | Co 11.0 | Alloy 41 is a precipitation hardening alloy with high strength in the temperature range of 649°C to 982°C. |

| WASPALOY | N07001 | 19.50 | 53.00 | 4.25 | Co 13.5 | Waspaloy is an alloy with high temperature strength, excellent resistance to high-temperature corrosion and sulfuration at temperatures up to 982°C. It is used in jet engine turbine whels, buckets, spencers, and shafts. |

| A286 | S66286 | 14.75 | 25.50 | 1.25 | Fe 56.0 | A286 is an age-hardenable Fe-Ni-Cr alloy with high strength and corrosion resistance at high temperatures. |

| Alloys Name | UNS No. | Cr | Ni | Mo | Others* | Discription |

| Typical Chemical Compositions [mass%] | ||||||

*For detailed information on chemical compositions, Please click on the alloys name.

These products or equivalent alloys will be used for manufacturing

*HAYNES® - Registered Trademark of Haynes International, Inc.

Please click on the alloy name to go to the detailed page of each alloy.

The table below lists only typical compositions. Please refer to the detail pages for other compositions.

Please scroll horizontally to view.

| Alloys Name | UNS No. | Typical Chemical Composition [mass%] | Discription | |||

|---|---|---|---|---|---|---|

| Cr | Ni | Co | Others | |||

| MP35N® | R30035 | 20.00 | 35.00 | 35.00 | Mo 10.0 | MP35N is classified as a non-magnetic Co-Ni-Cr-Mo (Cobalt-Nickel-Chromium-Molybdenum) alloy which has very high strength, excellent corrosion resistance, and high fatigue strength. It has high resistance to stress corrosion cracking caused by sulfides and shows excellent performance in natural gas drilling in high hydrogen sulfide atmospheres. In seawater, it has the highest resistance to crevice corrosion, stress corrosion and pitting. Additionally, this is often used in medical applications such as implants and dental instruments because of its high biocompatibility. It is also used in temperatures ranging from cryogenic to 454°C. TOKKIN supplies a wide variety of shapes, including foils and sheets, as well as ultrafine pipes, rods, and plates. |

| L605 | R30605 | 20.00 | 10.00 | 51.00 | W 15.0 | L605 has good strength, carburization resistance, and oxidation resistance properties in high-temperature atmospheres, it is often used in jet engine components and afterburner parts. |

| Alloy 188 | R30188 | 22.00 | 22.00 | 39.00 | W 14.5 | Alloy 188 is a cobalt-based Co-Ni-Cr-W (Cobalt-Nickel-Chromium-Tungsten) alloy with excellent resistance to high temperature and high temperature corrosion environments up to 1093°C (2000°F). |

| Alloys Name | UNS No. | Cr | Ni | Co | Others | Discription |

| Typical Chemical Compositions [mass%] | ||||||

Please click on the alloy name to go to the detailed page of each alloy.

The table below lists only typical compositions. Please refer to the detail pages for other compositions.

Please scroll horizontally to view.

| Alloys Name | UNS No. | Typical Chemical Compositions [mass%] | Discription | |||

|---|---|---|---|---|---|---|

| C max |

Fe max |

Ti | Others | |||

| TITANIUM Grade1 | R50250 | 0.08 | 0.20 | Bal. | TITANIUM Grade1 is a pure titanium of high purity, and by controlling the grain size appropriately, it is possible to get elongation properties suitable for deep drawing. | |

| TITANIUM Grade2 | R50400 | 0.08 | 0.30 | Bal. | TITANIUM Grade2 is a pure titanium used for applications requiring elongation and formability. | |

| TITANIUM Grade4 | R50700 | 0.08 | 0.50 | Bal. | TITANIUM Grade4 is a pure titanium with high strength. | |

| TITANIUM Grade7 | R52400 | 0.08 | 0.30 | Bal. | TITANIUM Grade7 is a titanium alloy with excellent weldability, workability and corrosion resistance. | |

| TITANIUM Grade11 | R52250 | 0.08 | 0.20 | Bal. | TITANIUM Grade11 is a titanium alloy with corrosion resistance in chloride environments. | |

| Beta 21S | R58210 | 0.05 | 0.40 | Bal. | Mo 15.0 Al 3.0 Nb 2.8 |

Beta 21S is metastable beta titanium that can be cold worked and has high oxidation resistance properties. |

| TITANIUM Grade9 (Ti-3-2.5) | R56320 | 0.05 | 0.30 | Bal. | Al 3.0 V 2.5 |

TITANIUM Grade9 (Ti-3-2.5) is an alpha and beta titanium with excellent weldability, workability and corrosion resistance. |

| Alloys Name | UNS No. | C max |

Fe max |

Ti | Others | Discription |

| Typical Chemical Compositions [mass%] | ||||||