High strength can be achieved through quenching, making our steel suitable for a variety of blades, including razor blades, cutter blades, and medical blades. We control the grain size using our proprietary rolling and heat treatment technologies, which enhance hardenability, workability for blade attachment, and wear resistance. In addition to high carbon steels, we also produce various types of stainless steels, allowing you to select the most suitable steel grade based on your specific applications and required properties.

Razor Blades, Electric Shaver Blades, Cutter Blades, Medical Scalpel Blades, Long Blades, Cutting Tools, Band Saws, Thomson Blades, Pinnacle Blades, Various Other Cutting Tools, Doctor Blades, Scales, Trowels, Scrapes

Thickness: 0.030-2.0mm *Availability may vary by steel grade.

Width: 3-300mm *Contact Sales if your desired values is over 300mm.

Length: COIL or -2000mm

Please scroll horizontally to view.

| Type | Grade | Features |

|---|---|---|

| High Carbon Steel | TE-2 [TOKKIN Original Product] |

TE-2 is our original steel grade. It is an improved grade of alloy tool steel SKS81 with improved hardenability by adjusting the composition and strictly controlling the manufacturing history, and has finer carbides to improved sharpness and wear resistance. It is used for razor blades and other high-grade blades. |

| SK95(SK4) | Classified as carbon tool steel, these grades have a lower carbon content than TE-2, which results in reduced hardness after quenching. However, they are versatile materials in terms of workability, hardenability, and cost. As a result, they are used in a wide range of applications, such as cutter blades, band saws, and tape measures. | |

| SK85(SK5) | ||

| Martensitic Stainless Steel |

SUS420J2 | Martensitic stainless steels are widely used in various fields due to their marketability and price. Our annealed finish makes the carbides completely spheroidized, making processing easier and has excellent hardenability. |

Please scroll horizontally to view.

[mass%]

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo | Fe | Others |

|---|---|---|---|---|---|---|---|---|---|---|

| TE-2 | 1.20-1.30 | 0.15-0.35 | 0.35 max | 0.030 max | 0.020 max | 0.30-0.50 | 0.25 max | - | Bal. | Cu 0.25 max |

| SK95 (SK4) |

0.90-1.00 | 0.10-0.37 | 0.10-0.50 | 0.030 max | 0.030 max | 0.30 max | 0.25 max | - | Bal. | Cu 0.25 max |

| SK85 (SK5) |

0.80-0.90 | 0.10-0.39 | 0.10-0.50 | 0.030 max | 0.030 max | 0.30 max | 0.25 max | - | Bal. | Cu 0.25 max |

| SUS420J2 | 0.26-0.40 | 1.00 max | 1.00 max | 0.040 max | 0.030 max | 12.00 -14.00 |

- | - | Bal. | - |

Please scroll horizontally to view.

| Grade | Density [g/cm3 ] |

Specific Heat [J/(kg・K)] |

Electrical Resistance [μΩ・cm] |

Young's Modulus [GPa] |

Thermal Expansion [×10-6/K] |

Thermal Conductivity [W/(m・K)] |

|---|---|---|---|---|---|---|

| SK95(SK4) SK85(SK5) |

7.84 | 420 | 18 | 208 | 11 | 50.2 |

| SUS420J2 | 7.75 | 460 | 55 | 200 | 10.3 | 24.7 |

We offer materials in either an annealed or cold-rolled finish for your selection. Please refer to the table below to submit your request.

You may also specify a finish that is intermediate between annealed and fully hardened.

Please scroll horizontally to view.

| Grade | Hardness[HV] | ||

|---|---|---|---|

| As annealed /As cold rolled | After Heat Treatment (Reference) |

||

| Annealed | Full Hardened | Quenching and Tempering | |

| TE-2 | 170-210 | 280-320 | 650-850 |

| SK95(SK4) | 160-200 | 270-310 | 620-820 |

| SK85(SK5) | 150-190 | 260-300 | 600-800 |

| SUS420J2 | 160-210 | 290-350 | 450-550 |

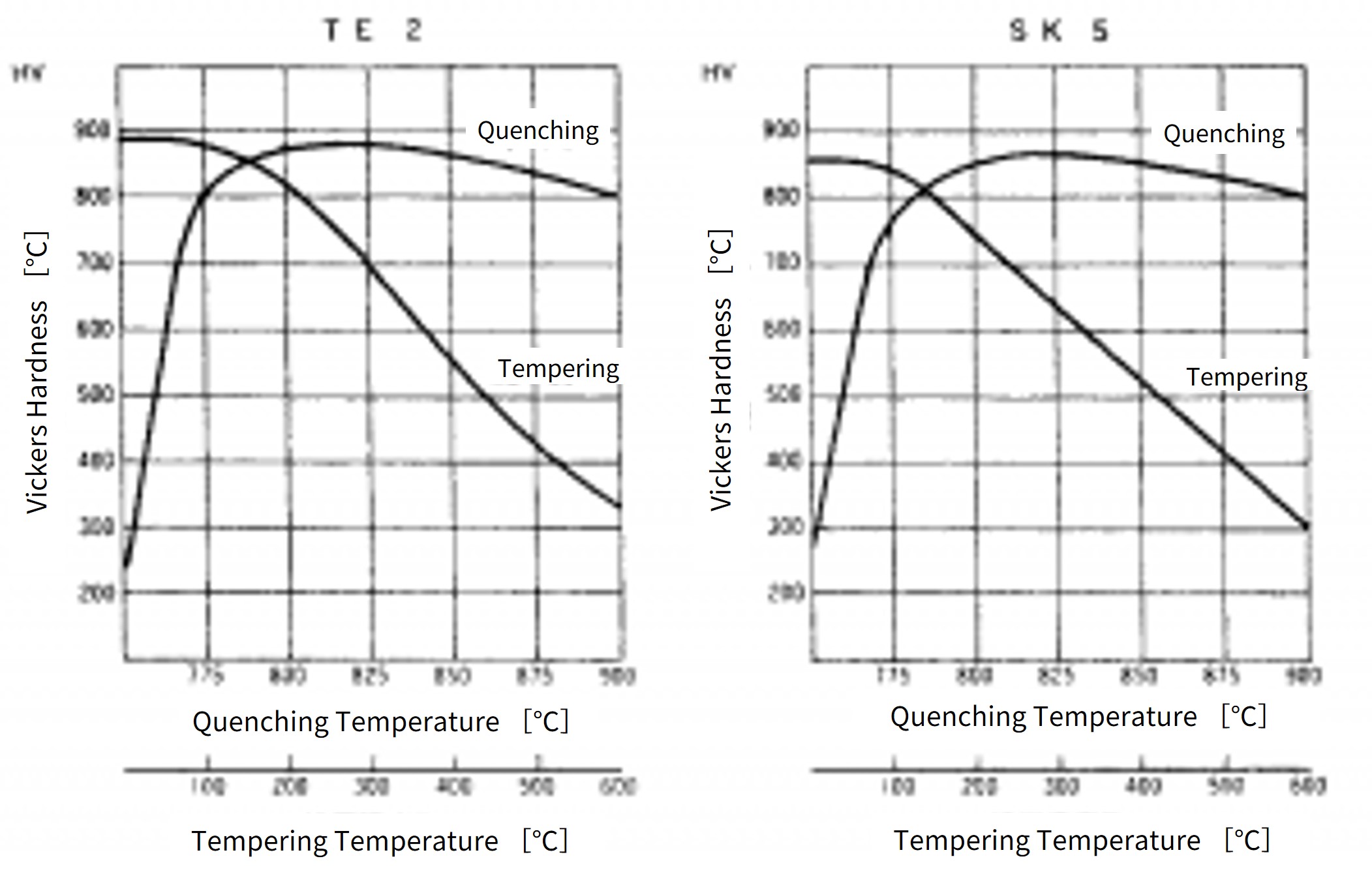

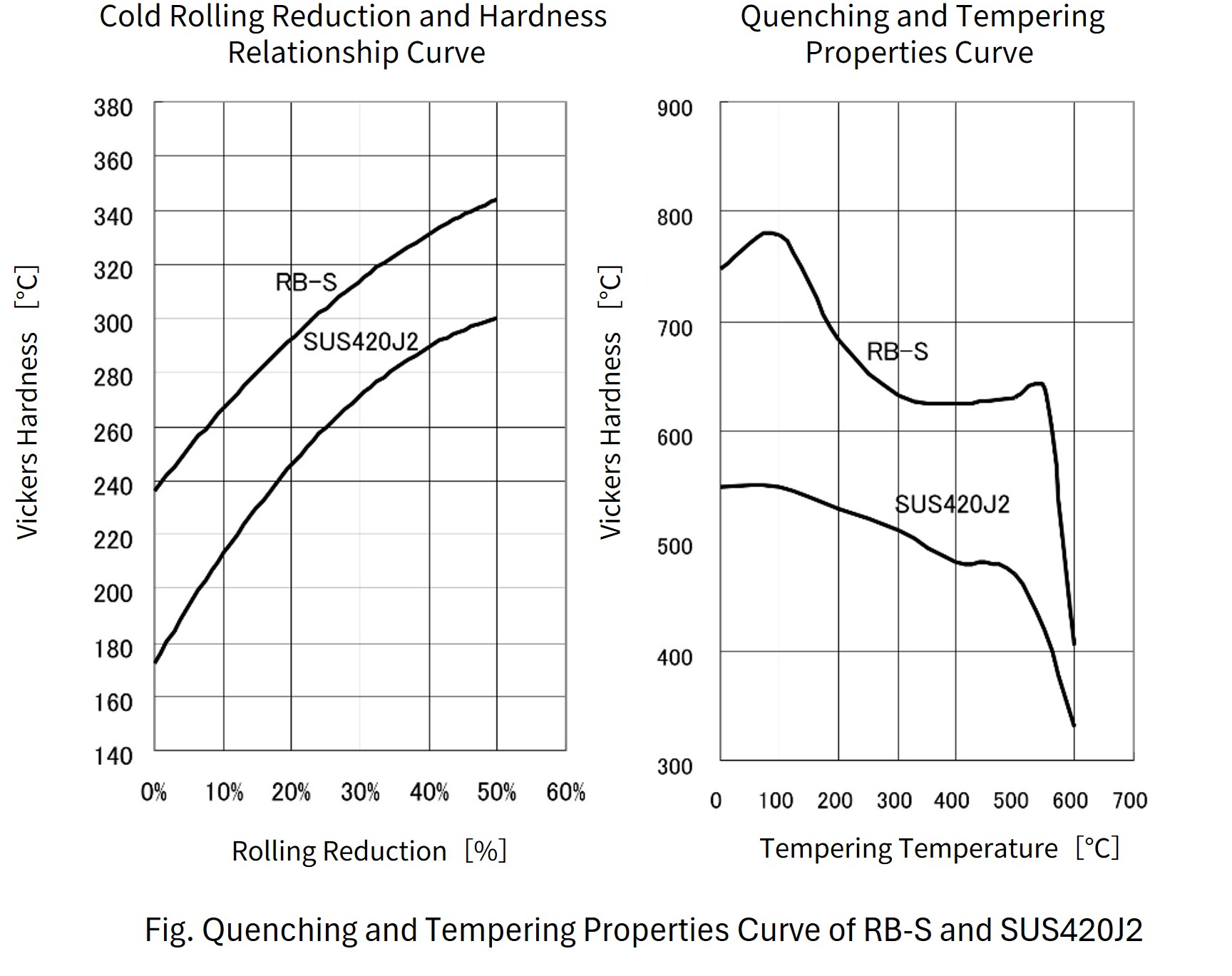

After achieving the optimal condition through quenching, it is important to perform tempering before the product is used. The relationship between tempering temperature and hardness is illustrated in the figure below. However, since this relationship can vary based on product size and the desired properties, it is advisable to conduct tests before making a final decision.

Fig. Quenching and Tempering Properties Curve of TE-2 and SK5

Fig. Quenching and Tempering Properties Curve of SUS420J2

It can be used for spring parts because high strength is achieved through cold rolling and heat treatment. Please click here to see the differences among each steel grade.