General Steels made under normal manufacturing conditions inevitably contain some non-metallic inclusions during its steel making process, which can often be a problem in applications where high reliability is required.

MB-1, M1, and M2 are uniquely developed steel grades designed for knitting needles and textile machinery parts. These grades are based on SK95 and feature fewer inclusions due to adjustments in composition and the steel-making process, resulting in high cleanliness. Additionally, they aim to enhance fatigue resistance and wear resistance by incorporating elements such as Manganese, Chromium, and Molybdenum, while strictly controlling the metallic structure.

Knitting Needles, Knitting Related Parts, Textile Machinery Parts

Thickness: 0.010-2.0mm *Availability may vary by steel grade.

Width : 3.0-300mm *Contact Sales if your desired values is over 300mm.

Length : COIL or -2,000mm

| MB-1 [TOKKIN Original Product] |

This grade was developed with the aim of achieving high durability to withstand long hours of continuous and high speed use. It has higher cleanliness than made from conventional converter, and its strictly controlled metallurgical structure provides excellent fatigue resistance and wear resistance. |

|---|---|

| M1 [TOKKIN Original Product] |

This grade offers excellent heat treatment properties and high cleanliness in textile machinery parts, with improved wear resistance due to the addition of Molybdenum. Its workability matches that of SK95. |

| M2 [TOKKIN Original Product] |

This steel grade is designed to enhance wear resistance by incorporating higher levels of Carbon, Manganese, and Chromium compared to SK95. Additionally, it aims to improve cleanliness and durability by maintaining low levels of Phosphorus and Sulfur. Due to its excellent heat resistance, high cleanliness, and controlled material surface, this steel is recommended for use in knitting-related components that require high reliability. |

Please scroll horizontally to view.

[mass%]

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo | Fe | Others |

|---|---|---|---|---|---|---|---|---|---|---|

| MB-1 | 0.95-1.05 | 0.15-0.35 | 0.50-0.70 | 0.010 max | 0.005 max | 0.30-0.45 | 0.10 max | 0.050 max | Bal. | V 0.050 max |

| M1 | 0.90-1.00 | 0.15-0.35 | 0.35-0.50 | 0.030 max | 0.007 max | 0.20-0.30 | 0.25 max | 0.01-0.02 | Bal. | Cu 0.25 max |

| M2 | 0.95-1.05 | 0.15-0.35 | 0.60-0.80 | 0.026 max | 0.010 max | 0.35-0.45 | 0.25 max | 0.02-0.03 | Bal. | Cu 0.25 max |

| SK95M (reference) |

0.90-1.00 | 0.10-0.37 | 0.10-0.50 | 0.030 max | 0.030 max | 0.30 max | 0.25 max | - | Bal. | Cu 0.25 max |

The cleanliness standards as specified by JIS G0005:Microscopic testing method for the non-metallic inclusions in steel(point calculation method)is shown in the table below.

| Grade | dA | dB | dC | dT |

|---|---|---|---|---|

| MB-1 | 0.004 | 0.004 | - | 0.008 |

| M1 | 0.021 | - | - | 0.021 |

| M2 | 0.013 | - | - | 0.013 |

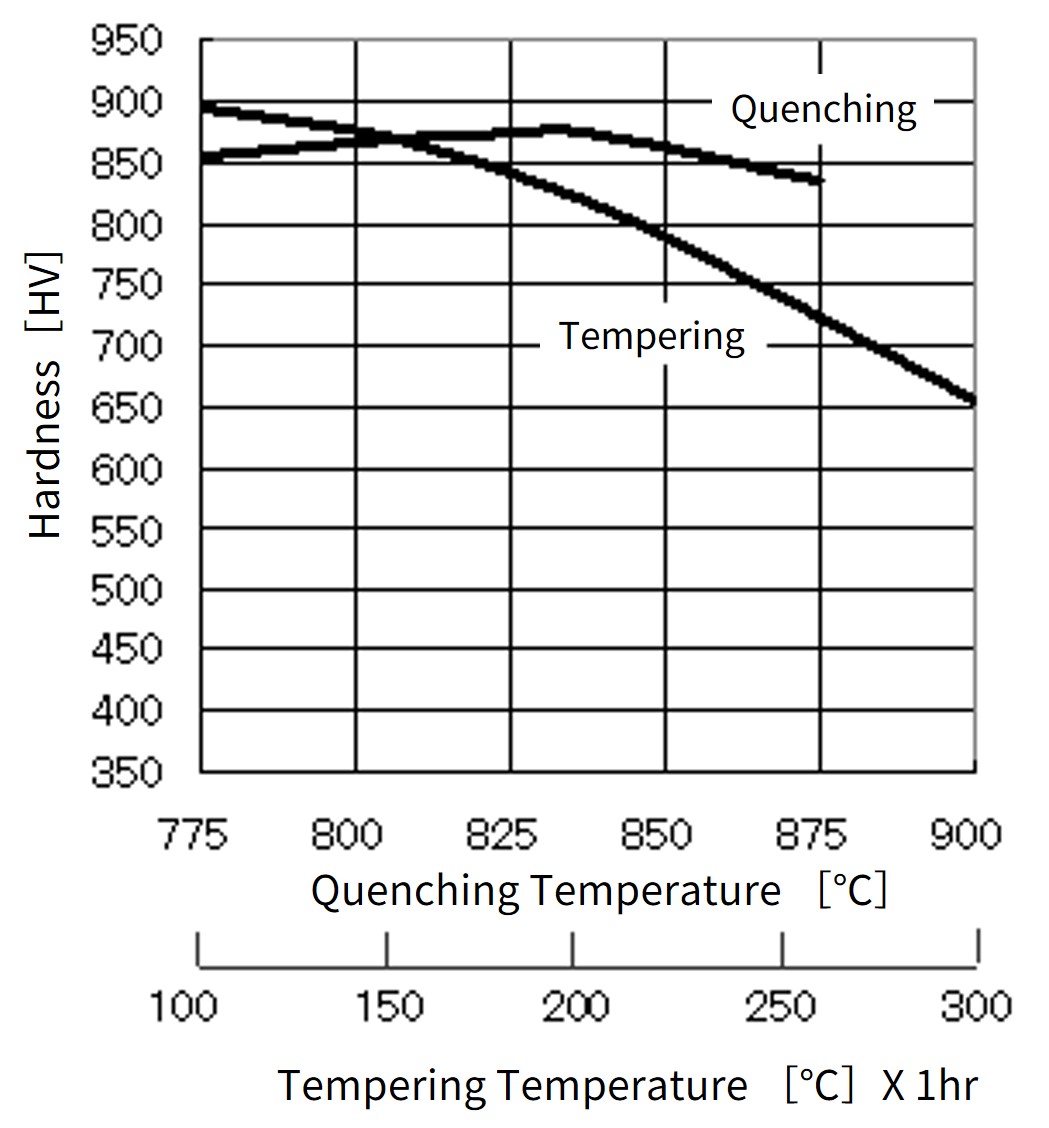

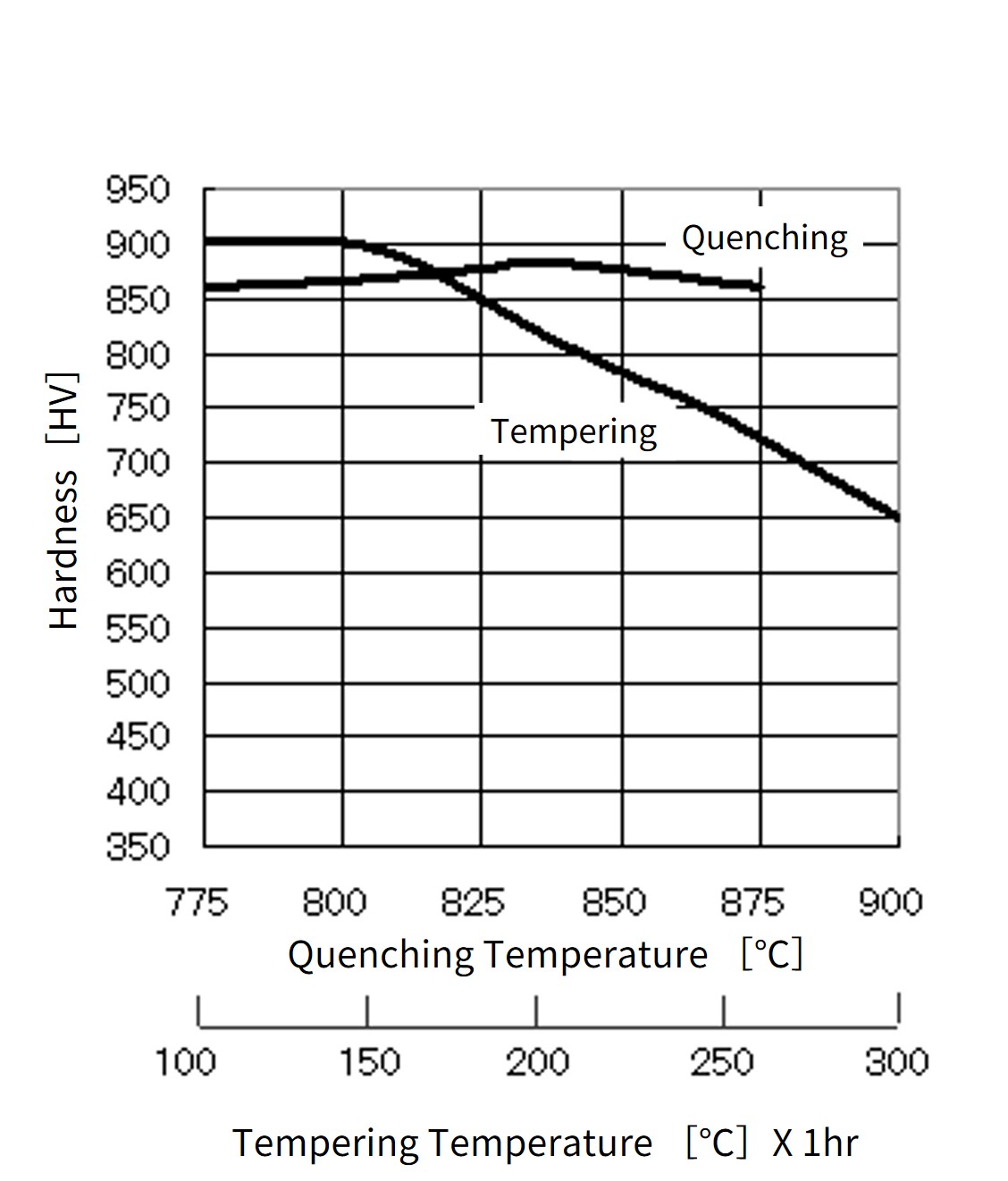

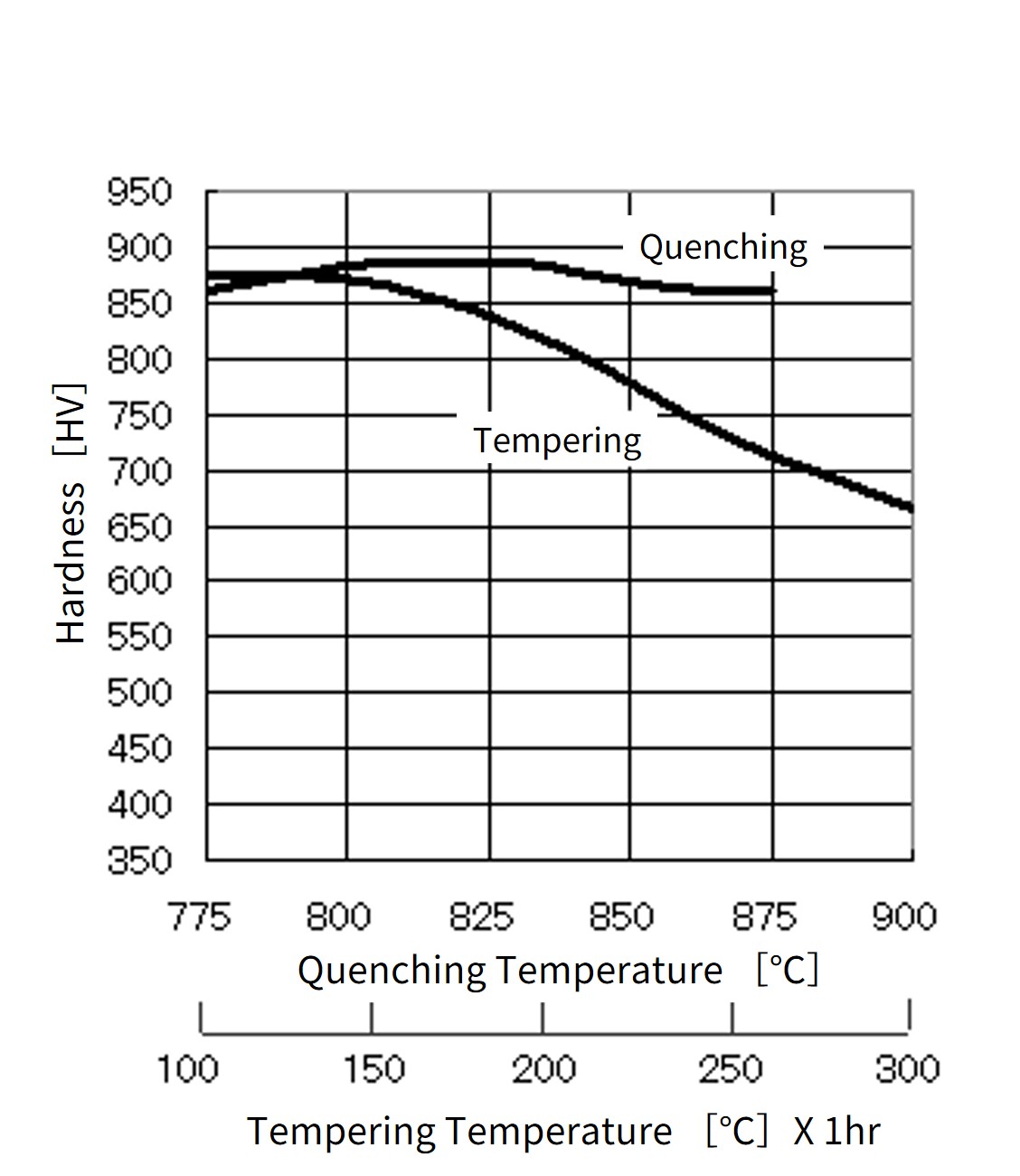

The general quenching conditions for each steel grade are outlined in the table below.

| Grade | Quenching Temperature | |

|---|---|---|

| Oil Cooling | Water Cooling | |

| MB-1 | 780-850℃ | 760-820℃ |

| M1 | ||

| M2 | ||

Typical mechanical properties after heat treatment, including quenching and tempering, are displayed in the table below. Please adjust the heat treatment conditions based on the specific application and required properties.

| Grade | Hardness [HV] |

Tensile Strength [MPa] |

|---|---|---|

| MB-1 | 550-700 | 1765-2155 |

| M1 | 550-610 | 1765-2155 |

| M2 | 550-700 | 1765-2155 |

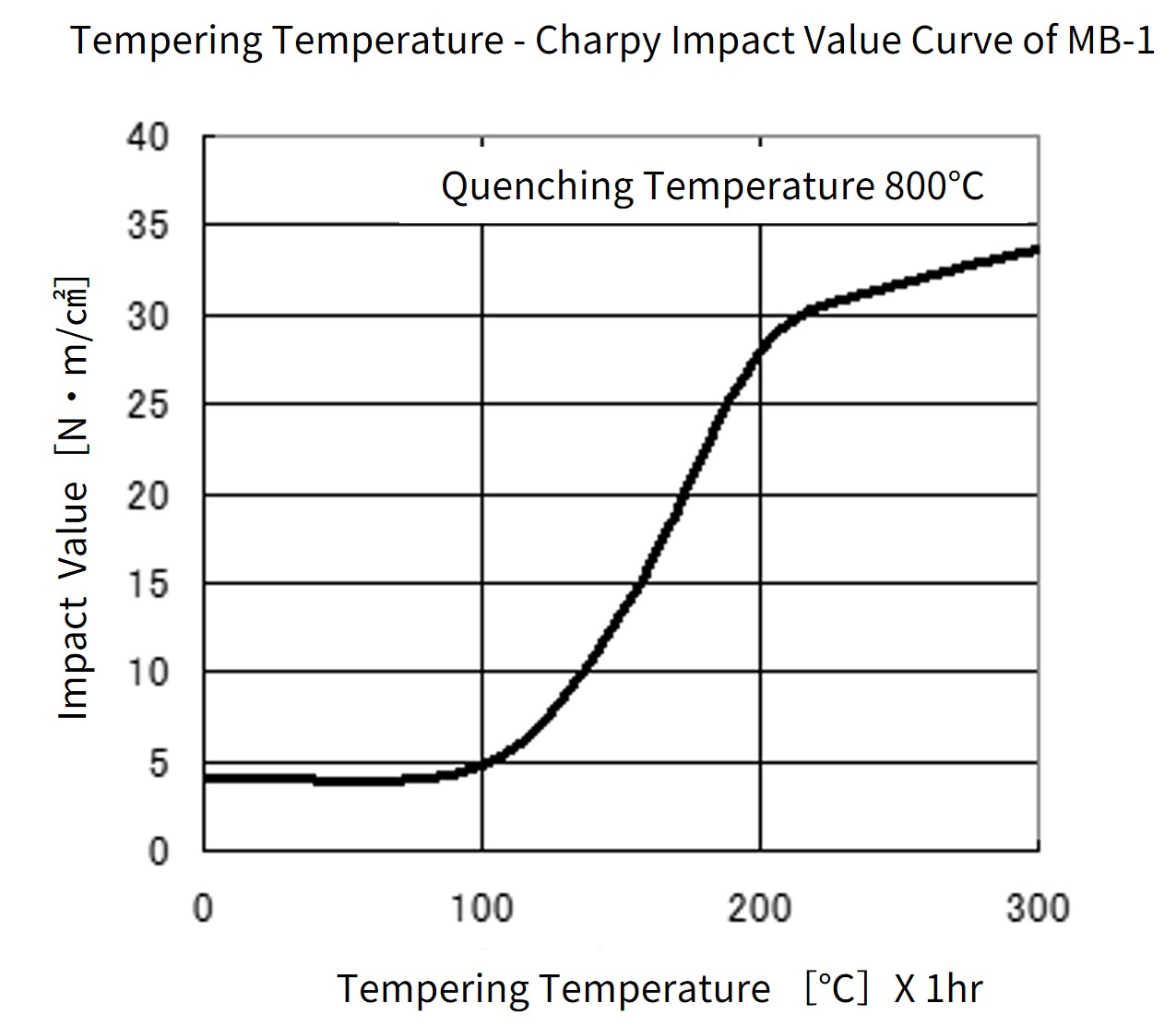

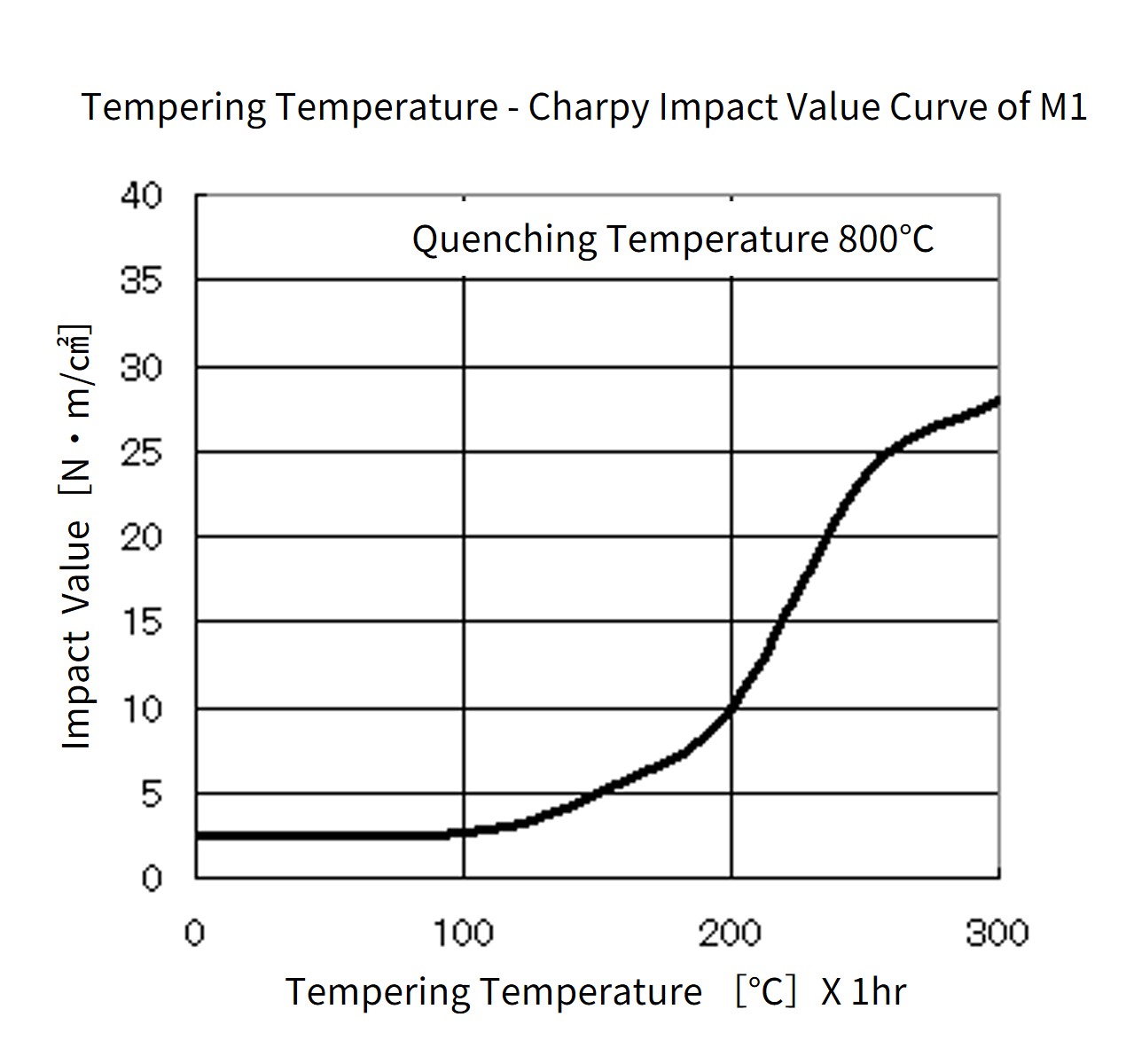

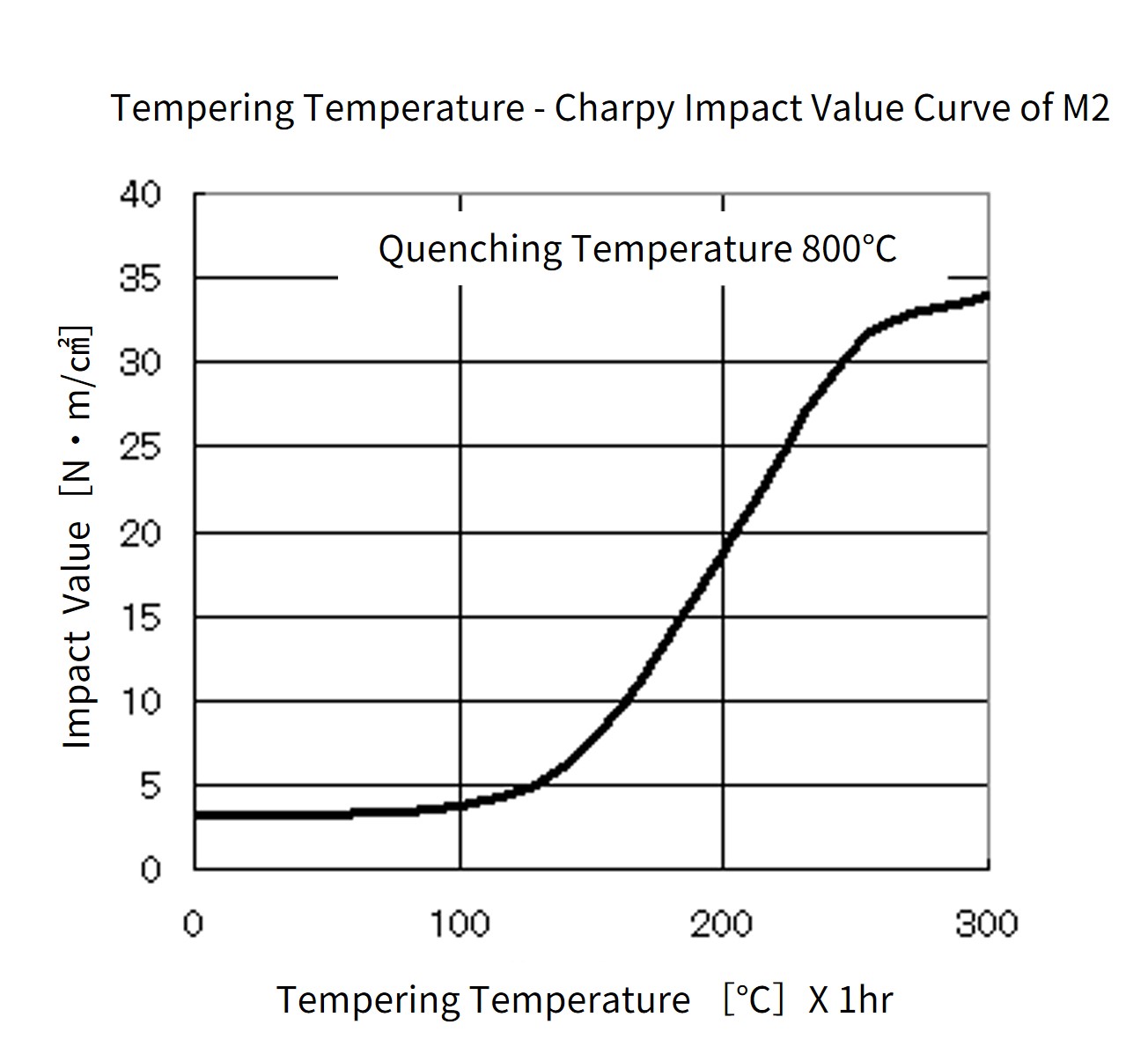

Impact values under general heat treatment conditions are shown in the figure below.

Please adjust the tempering conditions based on the applications and desired properties.

We can provide the following services.

You can see the features and properties of each cold-rolled special steel. If you are having difficulty with material selection, please check this page first.

Carbon tool steels are materials with high carbon content, widely used in various fields due to their workability, hardenability, product performance, and cost-effectiveness.