SOLDER | Molten-Solder Plated Metals

- HOME

- SEARCH MATERIALS

- Composite Metal Materials

- Composite Metal Materials

- SOLDER | Molten-Solder Plated Metals

Composite Metal Materials

Composite Metal Materials

SOLDER | Molten-Solder Plated Metals

Overview & Features

Strong adhesion can be obtained at the boundary between the base metal and the solder due to bonding by diffusion and chemical bonding by tin.

Molten-Solder Plated Metals is often used as a pre-soldering and has a significant effect on workability and productivity.

The features of our Molten-Solder Plated Metals:

(1) All of our Molten-Solder Plated Metals use lead-free solder in consideration of environmental issues. (2) Diffusion bonding prevents peeling and no surface preparation is required)(3) Jig manufacturing method enables inexpensive striped coating.

(4) Thick layer solder can be produced.

(5) Prevents whisker generation.

(6) Can be coated with a wide variety of solder components.

(7) Less solder dust during stamping.

Solder Coating Patterns

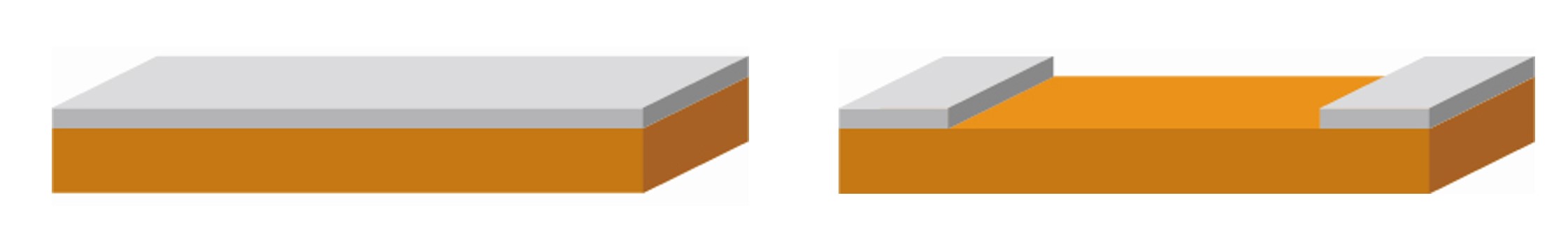

The figure below shows the examples of solder coating patterns.

Stripe is inexpensive due to roll coater method, but please keep in mind that the border area will be blotchy.

Detailed Information

Please contact us for more detailed information.

It is possible to combine with other composite metal materials.

Related Pages

Composite Metal Materials

Composite metal materials are materials composed of a single metal with additional functions. Combining multiple functions in a single product makes it possible to reduce the number of processes and reduce total costs.

Molten-Solder Plated Metals

Molten-Solder Plated Metals is a material in which a thin layer of molten solder is pre-coated on the base metal surface prior to stamping.

Related Products

Plated Rolled Materials

Rolling and heat treatment after plating eliminates pinholes in the plated layer and also has diffusion bonding at the boundary surface, which improves sliding wear resistance and adhesion. In the normal manufacturing process of clad metals (laminating multiple metals), the thickness of the clad part becomes thicker, and the cost of precious metal cladding tends to be high. However, in the case of Plated Rolled Materials, the thickness of the cladded part is almost the same as that of plating, cost reductions can be expected through a significant reduction in the amount of precious metal used.

Although the plating process itself is outsourced, we select the most suitable partner for each type of plating, and provide integrated services including rolling, heat treatment, plating and final quality assurance for Plated Rolled Materials.

Plating

Although the plating process itself is outsourced, we will select the most suitable material and outsourcing company depending on the type, quantity, and application of the plating. Of course, we provide final quality assurance including material and post plating process.

Features of our plating materials:

(1) Comprehensive management including materials and plating.(2) Combination of cold rolling and heat treatment on plated materials improves adhesion compared to normal plated materials

(3) Our experience with many plating manufacturers enables us to select the most suitable partner.