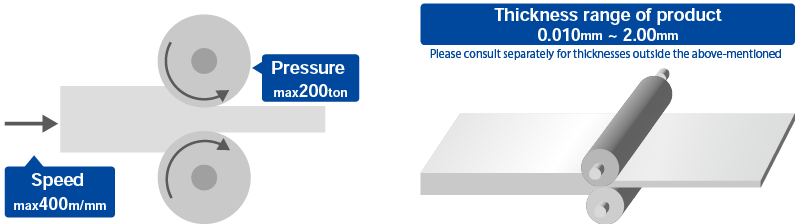

Cold rolling is one of a plastic forming process which room-temperature material is passed between rotating rolls and stretched thinner by applying pressure at the top and bottom.

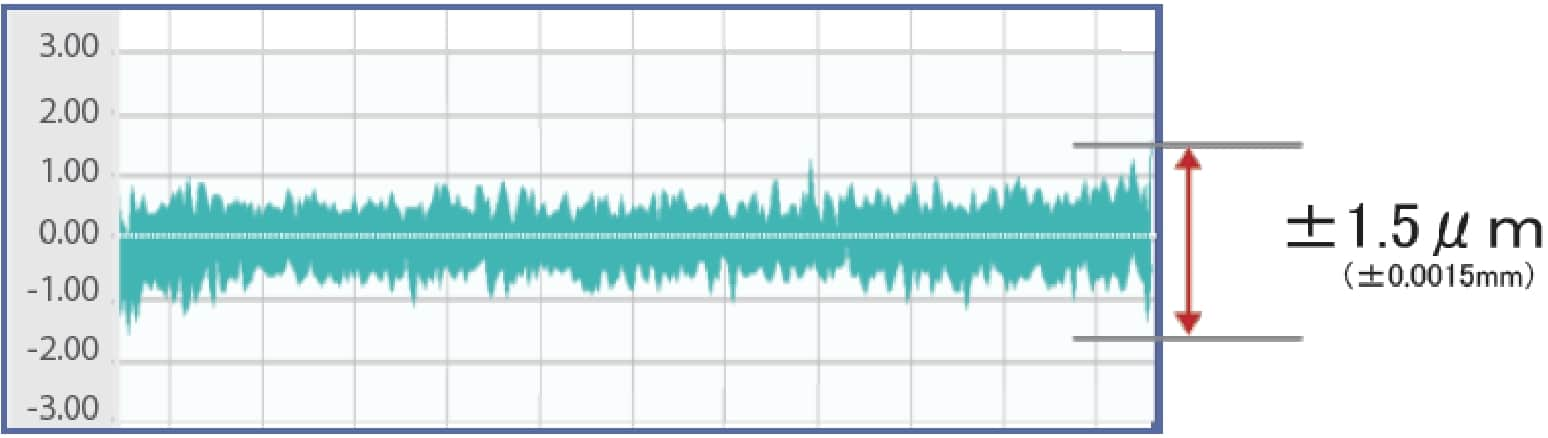

Our in-house designed rolling mills and Automatic Gage Control System built into rolling mills make it possible to controll the thickness with high precision.

What is a Plastic Forming?

This process uses the property of plasticity, which is the inability to return to the original shape after a certain amount of force is applied to deform it to create the desired shape.

This method generally reduces processing time and reduces material loss compared to other processing methods.

Compared to hot rolling, in which heated material is rolled, the plate thickness is more accurate and uniform, and can be processed to much thinner thicknesses.

Since an oxide film is not formed, a shiny surface finish can be produced. The internal structure can be made fine and homogeneous, leading to stabilization after part processing. In addition, mechanical properties (HV, TS, YS, EL) can be controlled.

The figure below is an example of the thickness chart measured with a thickness of 0.2 mm. The variation is within ±1.5μm (±0.0015mm) over the entire length.

Fig. Thickness chart measurement example (SUS301 t0.20mm)

Please scroll horizontally to view.

| Thickness & Width Manufacturing Range |

Remarks |

|---|---|

| Max t 2.50mm×w 340mm | Raw Material Rolling Intermediate Rolling Finishing Rolling |

| Max t 2.50mm×w 340mm | Intermediate Rolling Finishing Rolling |

| Max t 1.70mm×w 340mm | Intermediate Rolling Finishing Rolling |

Please scroll horizontally to view.

| Thickness & Width Manufacturing Range |

Remarks |

|---|---|

| Max t 1.50mm×w 310mm | Finish Rolling |

Please scroll horizontally to view.

| Thickness & Width Manufacturing Range |

Remarks |

|---|---|

| Max t 0.35mm×w 340mm | Finish Rolling |

Please scroll horizontally to view.

| Thickness & Width Manufacturing Range |

Remarks |

|---|---|

| Max t 0.20mm×w 100mm |

Please scroll horizontally to view.

| Thickness & Width Manufacturing Range |

Remarks |

|---|---|

| Max t 2.00mm×w 120mm |

Please scroll horizontally to view.

| Thickness & Width Manufacturing Range |

Remarks |

|---|---|

| Max t 4.00mm×w 150mm |

Please scroll horizontally to view.

| Thickness & Width Manufacturing Range |

Remarks |

|---|---|

| Max t 6.00mm×w 160mm | Cold-rolled cladding |