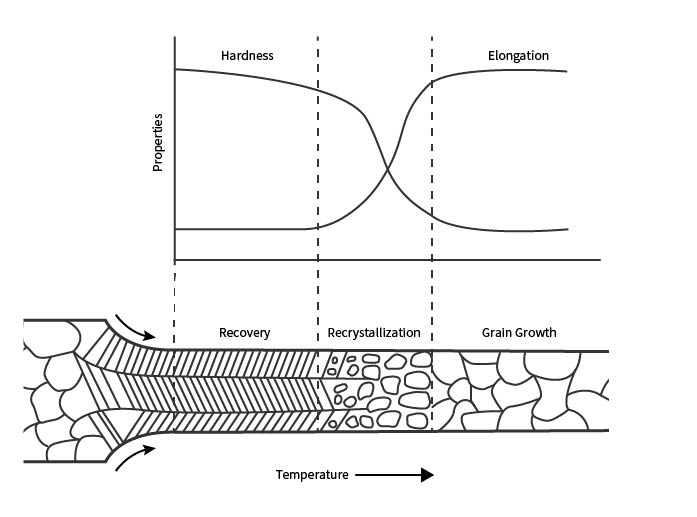

Heat treatment is performed to recover the metal structure changed by cold rolling (plastic deformation) and to remove residual stress and strain.

We use either a bell-type furnaces for heat treating coiled materials or continuous furnaces for heat treating non-coiled materials, depending on the material and purpose.

Changes in metallurgical structure and mechanical properties caused by plastic deformation and annealing

Annealing Furnace(BELL Type)

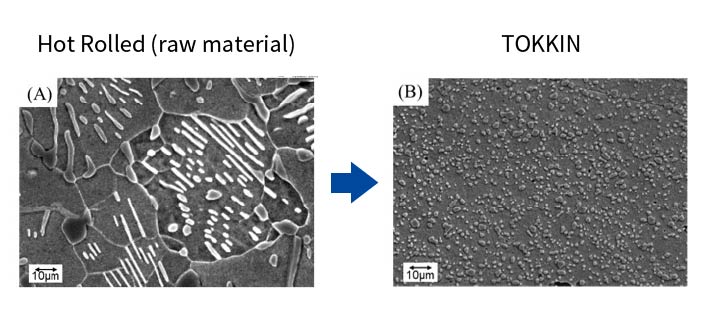

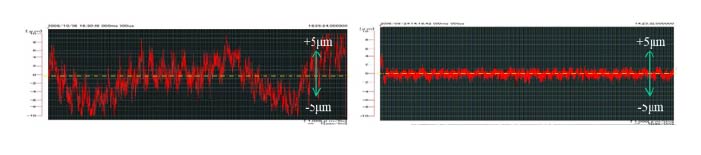

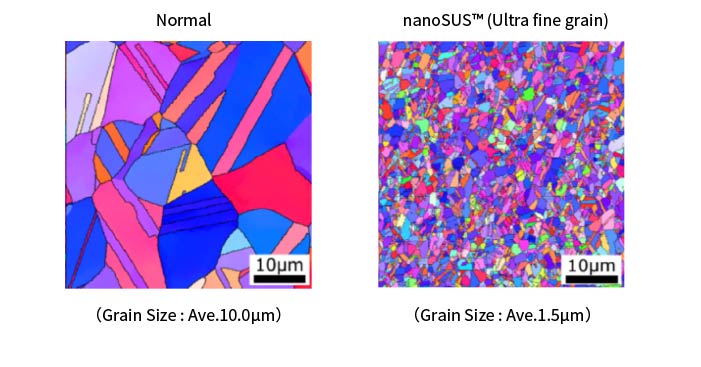

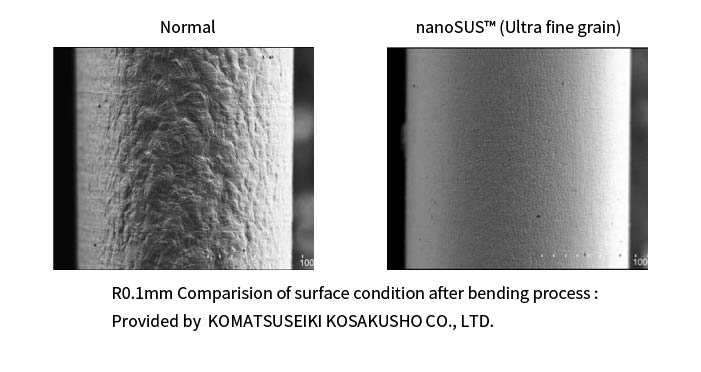

We control the internal structure of metals with our proprietary cold rolling and heat treatment know-how that we have cultivated over many years.

By controlling the metallurgical structure, workability, strength, and ductility can be adjusted.

| Type/Method | Temperature | Atmosphere Gas | Remarks |

|---|---|---|---|

| Annealing Furnace BELL Type/Electric heating |

~ 760℃ | H2/N2 | 2Bell-4Base |

| Annealing Furnace BELL Type/Gas heating |

~ 700℃ | H2/N2 | 1Bell-1Base |

| Bright Annealing Continuous furnaces |

~ 1150℃ | H2/N2 | Manufacturing Range: t0.030 ~ 1.00mm ×w340mmMAX t0.200 ~ 2.20mm ×w340mmMAX |

| ~ 850℃ | H2/N2 | Manufacturing Range: t0.040 ~ 1.70mm ×w130mmMAX |

| Type/Method | Temperature | Atmosphere Gas | Remarks |

|---|---|---|---|

| Tension Annealing Continuous furnaces |

~ 550℃ | N2 | Manufacturing Range: t0.030 ~ 0.70mm ×w340mmMAX |