Stainless Steels

Precipitation Hardening

SUS631 (17-7PH) | Precipitation Hardening Stainless Steel

Overview & Features

From the softest solution-treated to the hardest full hard rolled, depending on the processing and application, it is possible to have a strength second only to high-carbon martensitic quenched materials by applying various heat treatments.

In the solution heat-treated state, more than 30% elongation allows for strong processing such as drawing.

Please note that the material is weakly magnetic in the solution heat-treated state, but becomes quite strongly magnetic after precipitation hardening treatment.

This material is hard to obtain due to its relatively small distribution volume, and most of the materials distributed in stock sales are 3/4H finish. However, we can provide from the softest material in solution heat-treated condition (A material) to the hardest material with full hard finish (EH) per your use and processing method in small lot.

TOKKIN supplies a variety of stainless steels for springs as specified in JIS G4313.

Please refer to this page for the features and comparison of each grade of stainless steel for springs.

Examples of Applications

Diaphragms, Reed Valves, CPU/GPU Springs, Tire Mold Side Blades, Chains, Dental Equipment, Springs

Available Shapes

Manufacturable Range (COIL, SHEET)

Thickness

0.030-3.0mm

Width

3.0-300mm

Length

COIL or SHEET less than 2000mm

This is the manufacturing range of coils and sheets we manufacture.

For inquiries regarding procurement items, please contact us.

Standards

We manufacture in accordance with JIS G4313 standards.

Overseas standards are listed as equivalent or similar to our materials, so please use them as a reference.

JIS

SUS631 (G4305, G4313)

UNS

S17700

AISI/ASTM

631

EN

1.4568

ISO

X7CrNiAl17-7

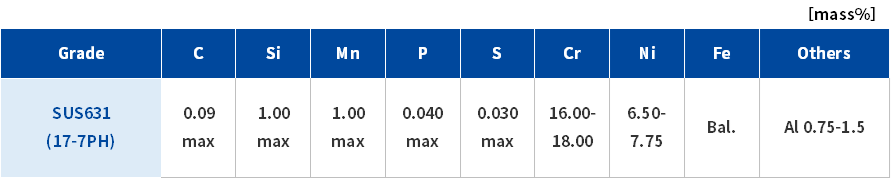

Chemical Composition

Physical Properties

Density

7.81 g/cm³

Specific Heat

420 J/(kg・K)

Electrical Resistivity

79 μΩ・cm

Young's Modulus

200 GPa

Thermal Expansion

15.3×10-6/K(0~100℃)

Thermal Conductivity

16.3 W/(m・K)

Melting Range

1414-1447 ℃

Magnetism

It is weakly magnetic in the solution heat-treated state, but becomes quite strong after precipitation hardening treatment.

Mechanical Properties

Unless otherwise specified, we manufacture in accordance with JIS standards (table below), but you can also specify stricter standards or custom specifications.

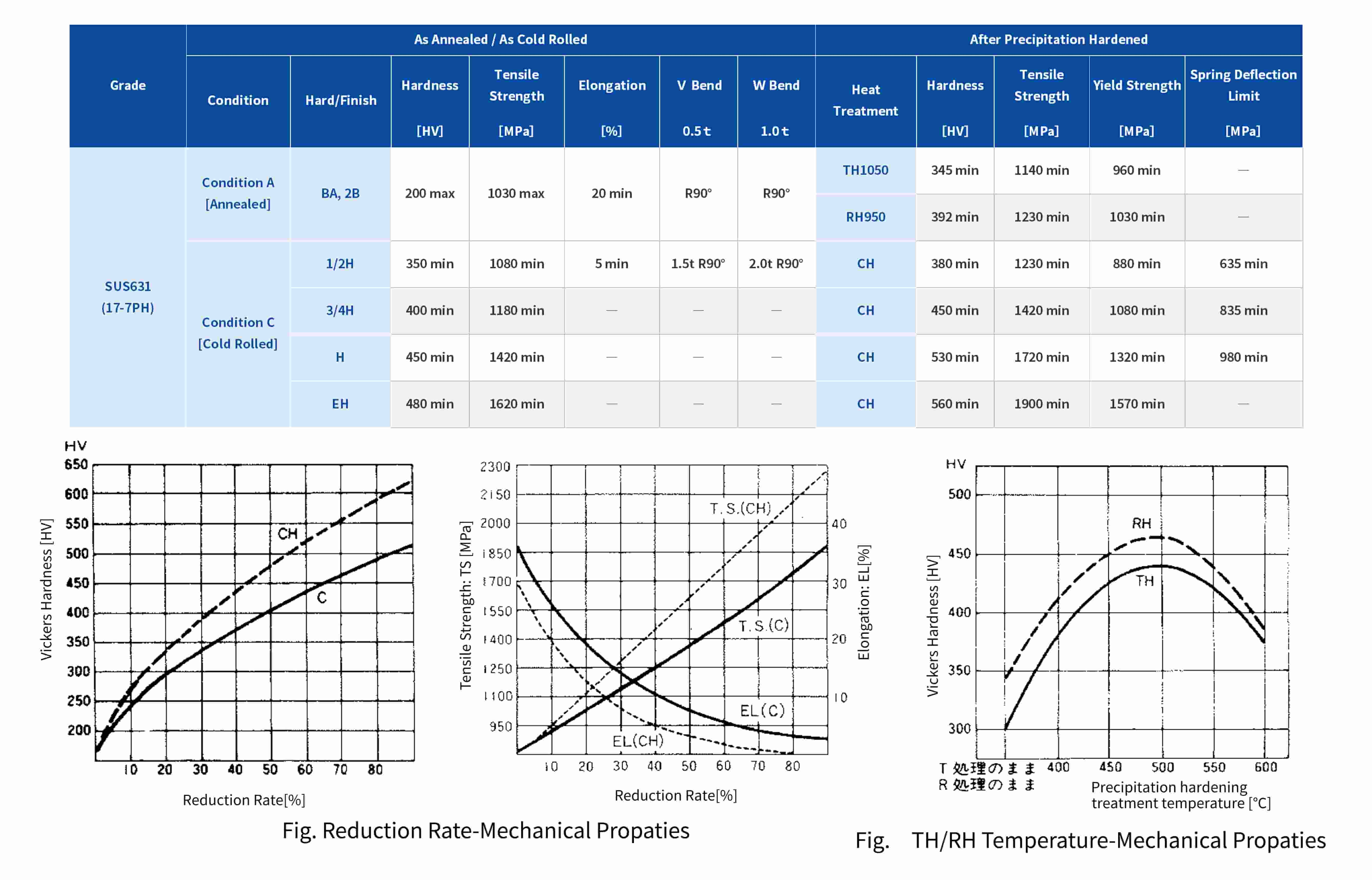

The mechanical properties of C materials and materials after CH treatment are shown in the figure below.

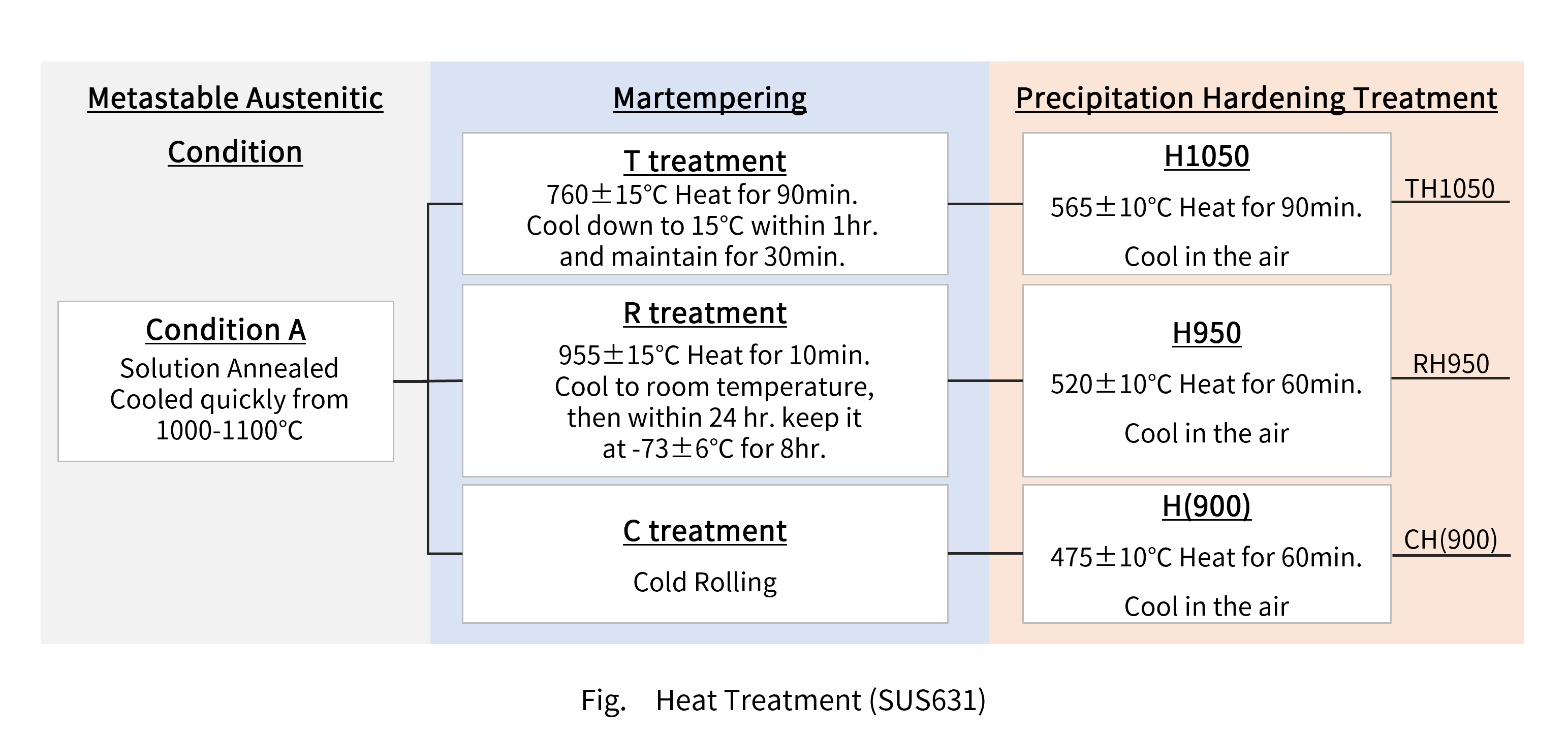

Heat Treatment

Age hardening(Precipitation Hardening) can be performed on SUS631 after precipitation hardening.

*Typical steel grades that precipitation hardened are stainless steels in the 600 series (SUS631, SUS632J2, TOKKIN 350, etc.) as well as maraging steels.

The method of precipitation hardening of SUS631 is shown in the figure below.

■TH1050、RH950 Treatmen

It is hardened by repeating two types of heat treatments. The first, T and R treatments are primary hardening heat treatments to martensitize the metastable austenite phase A material, like quenching in steel, while the second, H treatment is for complete hardening by causing precipitation hardening, the most distinctive feature of this steel grade.

*Precipitation hardening is not possible even if only H treatment is performed in the solid solution state (A material).

■CH(900) Treatment

Instead of martensitization by heat treatment, cold working is used for hardening. We provide cold-rolled C-materials with appropriate hardness, so customers only need to perform one more precipitation hardening heat treatment.

<Note>

・The numbers TH1050, RH950, and CH(900) represent the precipitation hardening treatment temperature in degrees Fahrenheit.

・We can provide A and C materials.

(Customers are requested to perform the hardening heat treatment of TH and RH.)

・Please refer to this article for more information on heat treatment.

Corrosion Resistance

The corrosion resistance of precipitation hardened stainless steels is generally inferior to that of austenitic stainless steels.

(Superior) Austenitic > Precipitation hardening > Ferritic > Martensitic (Inferior)

*It depends on the temper and environment, so please consult us first if you have specific issues.

Related Pages

Stainless Steels for Springs

This materials are possible to increase their hardness by rolling, they can be used as spring parts.

Precipitation Hardening Stainless Steels

These grades were developed with the concept of steels that are easy to form like austenitic stainless steels, and provide high strength like that of martensitic stainless steels.

Stainless Steels Foils (Under t0.10mm)

We offer not only thin stainless steel foils, but also propose the appropriate steel grade and temper depending on specific application and use requirements, such as strength, workablility, magnetism, and corrosion resistance.