Stainless Steels

Martensitic

RB-S | Martensitic Stainless Steel

Overview & Features

With a higher Carbon content compared to SUS420J2, great hardening occurs during quenching, it has the highest level of hardness among stainless steels. Because it is quite hard even after annealing, less suitable for complex processing, but it is an ideal material for blades.

Main features of RB-S:

(1) Suitable for Wear and Heat Resistant Applications.This grade is best suited for wear-resistant stainless steel applications, and can be used for heat-resistant applications due to its high tempering resistance.

(2) Less Mechanical and Physical Anisotropy

Due to the effect of microstructural transformation, it has less mechanical and physical anisotropy than austenitic spring materials that are hardened by cold rolling.

(3) Make thickness and width smaller.

Due to being a martensitic stainless steel, it has a higher Young's modulus compared to non-ferrous or austenitic stainless steels for springs. This allows the thickness and width of leaf springs to be reduced.

Examples of Applications

Electric Razors , Industrial Knives/Blades

Available Shapes

Manufacturable Range (COIL, SHEET)

Thickness

0.050-1.2mm

Width

3.0-300mm

Length

COIL or SHEET less than 2000mm

This is the manufacturing range of coils and sheets we manufacture.

Standards

TOKKIN's own grade of steel.

Standards are listed as equivalent or similar to our materials, so please use them as a reference.

AISI

420D

EN

1.4037

ISO

X65Cr13

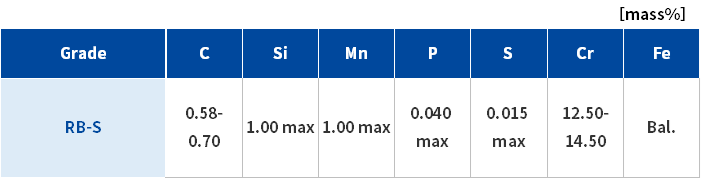

Chemical Composition

Physical Properties

Density

7.7 g/cm³

Specific Heat

430 J/(kg・K)

Electrical Resistivity

60 μΩ・cm

Young's Modulus

220 GPa

Thermal Conductivity

25 W/(m・K)

Magnetism

Strong

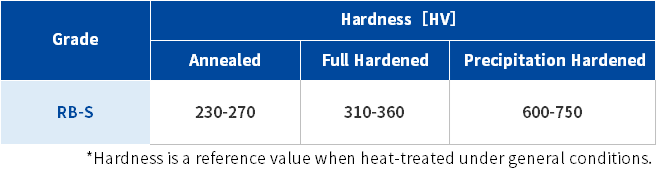

Mechanical Properties

We can manufacture according to your desired hardness between annealed to full hardened as shown in the table below.(The hardness of hardened steel strip is to be discussed each by each)

Some finishes may not be available depending on the thickness of the sheet, so please consult with us first.

*For ultra-thin foil, soft materials such as annealed or BA finish may not be applicable due to concerns about defects (folding, wrinkling, etc.).

Quenching and Tempering

RB-S can be hardened by quenching and tempering.

The max quenched hardness is[620-680HV].

Please select tempering temperature according to required hardness and toughness by referencing quenching and tempering curve.

Related Pages

Steels for Blades

Material which is used to make various blades such as razor blades, shaver blades, and medical blades. Depending on the application and required properties, you can choose from a variety of options such as high carbon steel or martensitic stainless steel.

Martensitic Stainless Steels

They have a high carbon content and can acquire extremely high strength if quenched after stamping.

Hardened Stainless Steels

We provide quenched stainless steel strips.