Alloy X

Nickel, Cobalt, and Titanium Alloys

Nickel Alloys

Alloy X

Overview & Features

Examples of Applications

Aerospace Applications, Industrial Gas Turbine Engine Combustion Chambers, Exhaust Pipes

Supported Shapes

Standards

Standards are listed as equivalent or similar to our materials, so please use them as a reference.

UNS

N06002

ASTM

B572

AMS

5536

JIS

NW6002(G4901-Bar/G4902-Strip, Sheet)

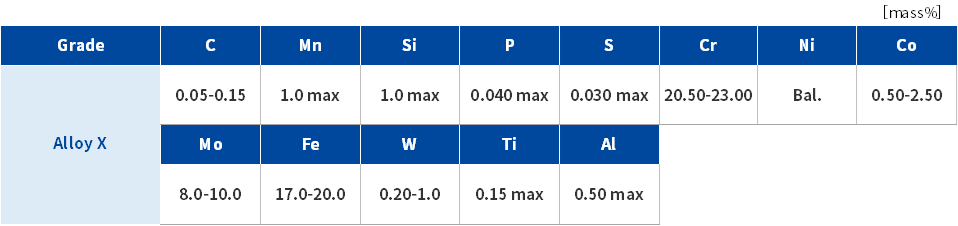

Chemical Composition

Physical Properties

Density

8.22 g/cm³

Electrical Resistivity

118 μΩ・cm

Related Pages

Superalloys(Nickel, Cobalt, and Titanium Alloys)

Materials based on Ni, Co, and Ti are superior to stainless steel in terms of corrosion resistance and heat resistance. In addition to cold-rolled strips manufactured by our company, we also provide thick plates, wires, bars, and ultra-thin pipes sourced from domestic and overseas partner companies for you.

Metal Foils (Under t0.10mm)

We can produce foil materials in all the materials we manufacture, from stainless steel, low carbon steel, high carbon steel, and other steel materials to nonferrous metals such as nickel alloys, cobalt alloys, and copper alloys.